Specications

Exploded View & Miscellaneous Parts

Block Diagram

Connection Diagram

Alignment

Board Unit (Schematics, Layouts & Parts)

MAIN Unit

BPF Unit

SCP Unit

CNTL Unit

LOCAL Unit

PA Unit

TUNER Unit

DSP Unit

FFT Unit

DISPLAY-1 Unit

DISPLAY-2 Unit

SW-A Unit

SW-B Unit

VR-A Unit

JACK Unit

MIC Unit

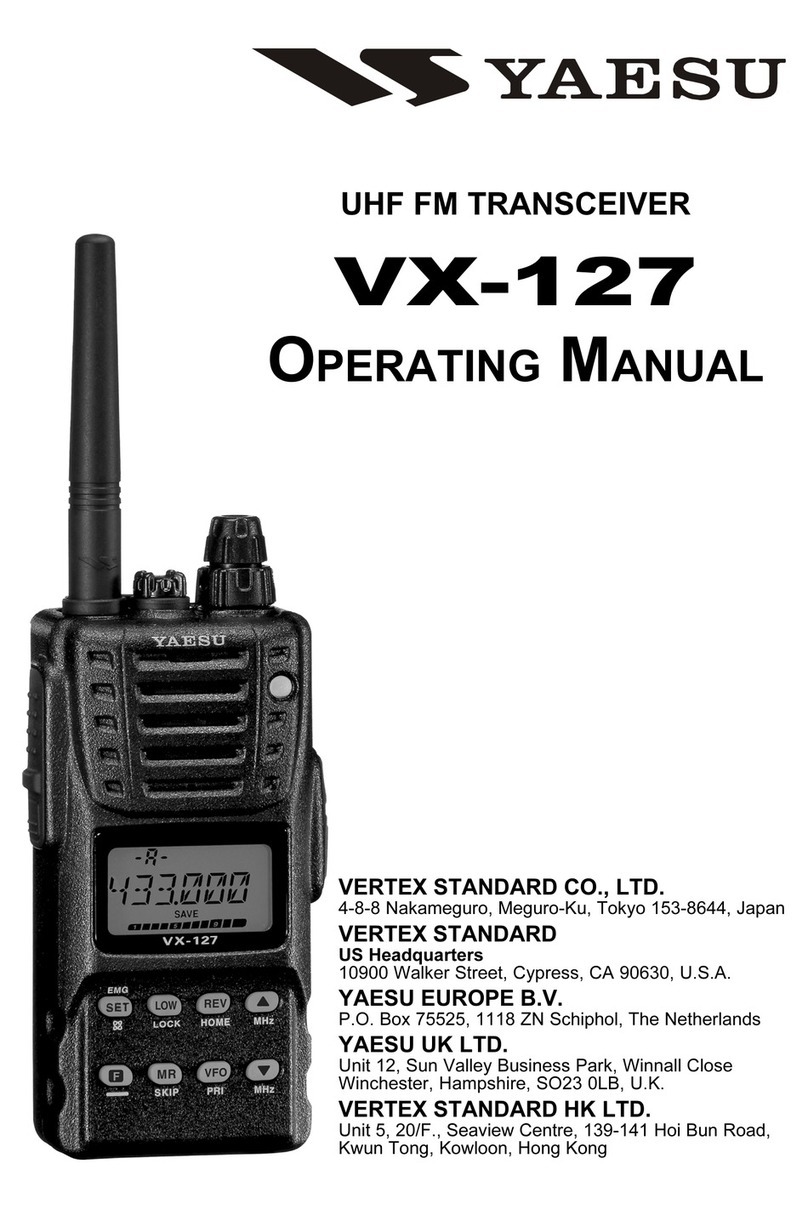

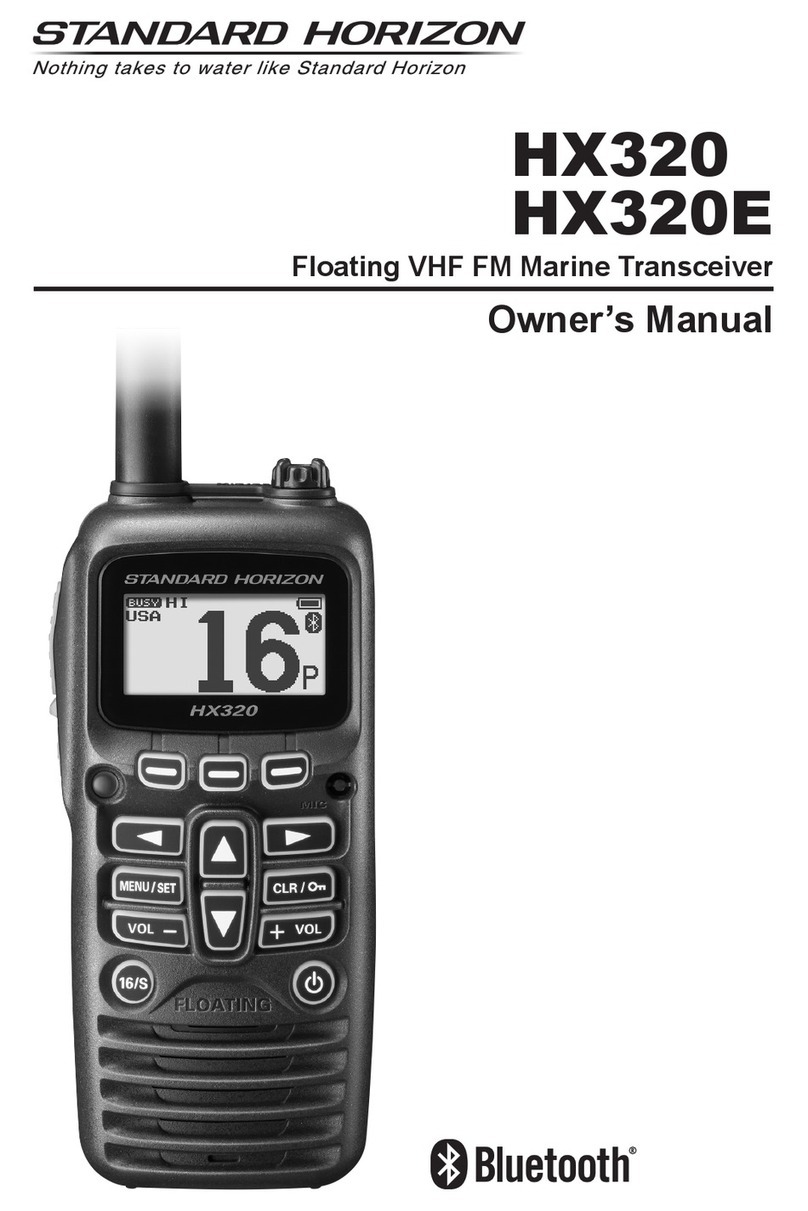

HF/50 MHz Transceiver

FTDX3000

Technical Supplement

©2013 YAESU MUSEN CO., LTD.

EH046H90A

YAESU MUSEN CO., LTD.

Tennozu Parkside Building

2-5-8 Higashi-Shinagawa, Shinagawa-ku, Tokyo 140-0002 Japan

YAESU USA

6125 Phyllis Drive, Cypress, CA 90630, U.S.A.

YAESU UK

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

YAESU HK

Unit 2002, 20/F, 9 Chong Yip Street,

Kwun Tong, Kowloon, Hong Kong

Introduction

This manual provides technical information necessary

for servicing the FTDX3000 HF/50 MHz Transceiver.

Servicing this equipment requires expertise in handling

surface-mount chip components. Attempts by non-

qualified persons to service this equipment may result

in permanent damage not covered by the warranty, and

may be illegal in some countries.

Two PCB layout diagrams are provided for each double-

sided circuit board in the Transceiver. Each side of is

referred to by the type of the majority of components

installed on that side ("leaded" or "chip-only"). In

most cases one side has only chip components, and

the other has either a mixture of both chip and leaded

components (trimmers, coils, electrolytic capacitors, ICs,

etc.), or leaded components only.

While we believe the technical information in this

manual to be correct, YAESU MUSEN assumes no

liability for damage that may occur as a result of

typographical or other errors that may be present. Your

cooperation in pointing out any inconsistencies in the

technical information would be appreciated.

Contents

Important Note

1) This transceiver was assembled using Pb (lead)

free solder, based on the RoHS specication.

Only lead-free solder (Alloy Composition: Sn-

3.0Ag-0.5Cu) should be used for repairs per-

formed on this apparatus. The solder stated

above utilizes the alloy composition required

for compliance with the lead-free specication,

and any solder with the above alloy composi-

tion may be used.

2) Risk of explosion if baery is replaced by an

incorrect type. Dispose of used batteries ac-

cording to the instructions.