Yamaha RCX222 User manual

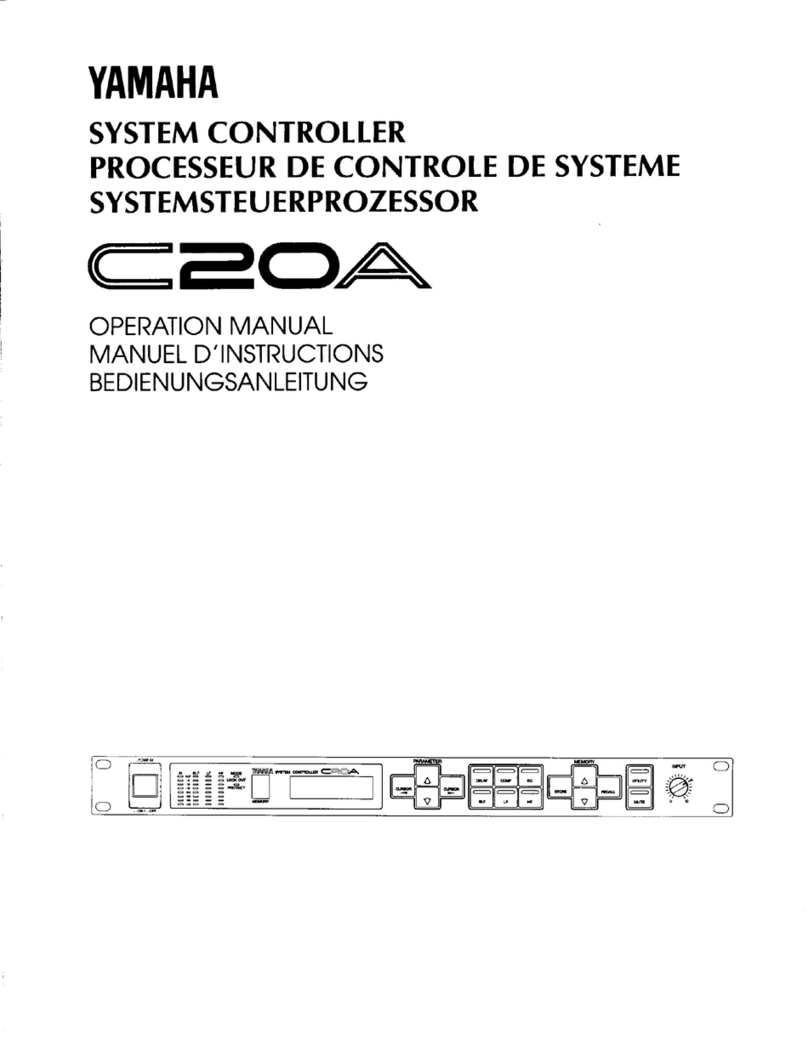

Other Yamaha Controllers manuals

Yamaha

Yamaha Mark IV User manual

Yamaha

Yamaha MJC8 User manual

Yamaha

Yamaha RCX142 User manual

Yamaha

Yamaha DRCX User manual

Yamaha

Yamaha RCX40 User manual

Yamaha

Yamaha RCX240 User manual

Yamaha

Yamaha RCX340 User manual

Yamaha

Yamaha disklavier DKC-850 User manual

Yamaha

Yamaha Nexo NXAMP4X4 User manual

Yamaha

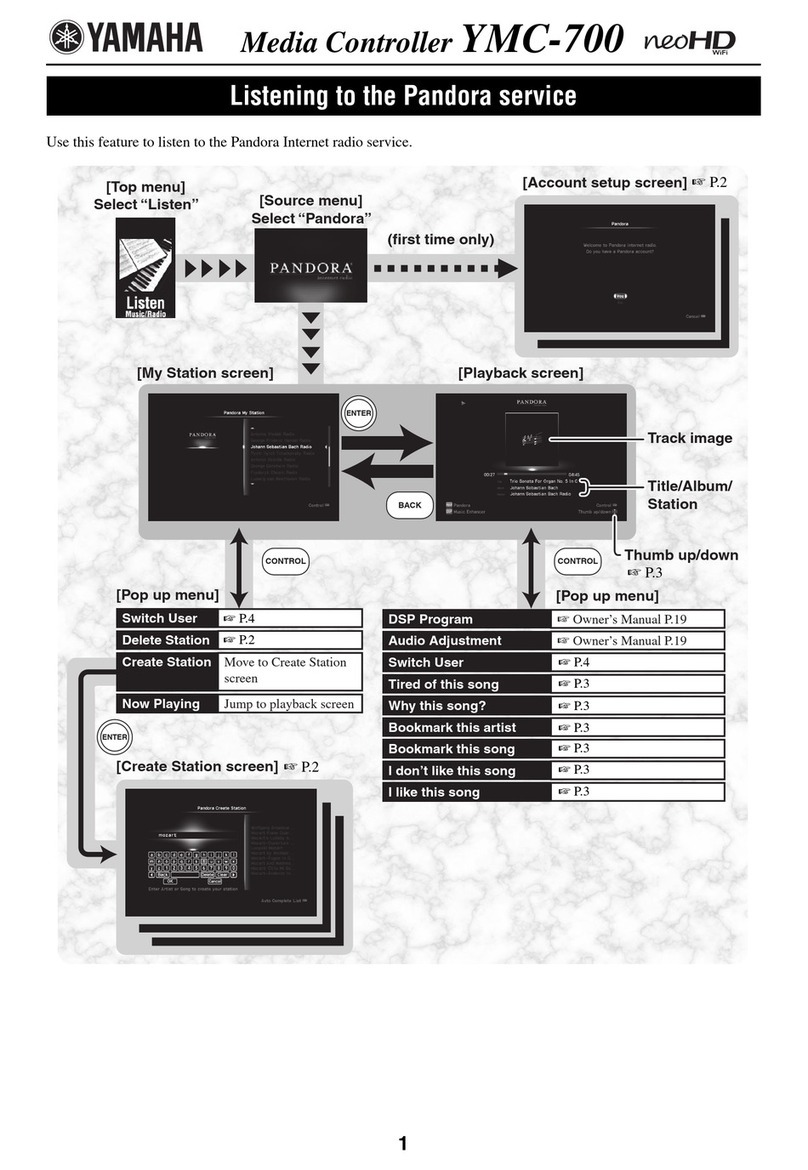

Yamaha neoHD YMC-700 User manual

Yamaha

Yamaha disklavier DKC-850 Parts list manual

Yamaha

Yamaha TS-P User manual

Yamaha

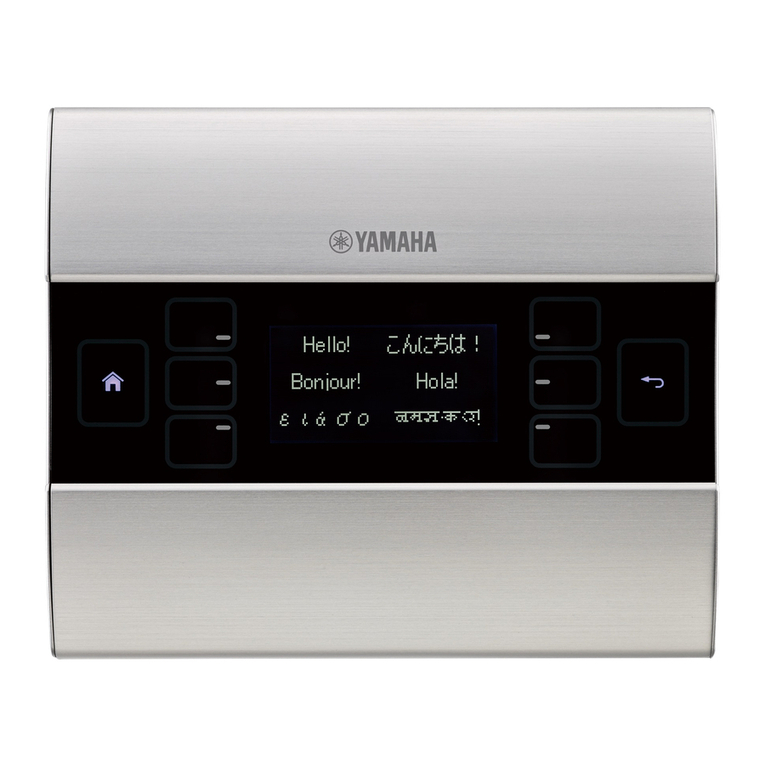

Yamaha MCP1 User manual

Yamaha

Yamaha SRCP30 User manual

Yamaha

Yamaha AFC1 User manual

Yamaha

Yamaha G10 User manual

Yamaha

Yamaha CEmarking RCX221 User manual

Yamaha

Yamaha SRCD Series Owner's manual

Yamaha

Yamaha ENSPIRE Controller User manual

Yamaha

Yamaha MCX-10 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions