6

INSTALLATION AND PREPARATION BEFORE

OPERATION

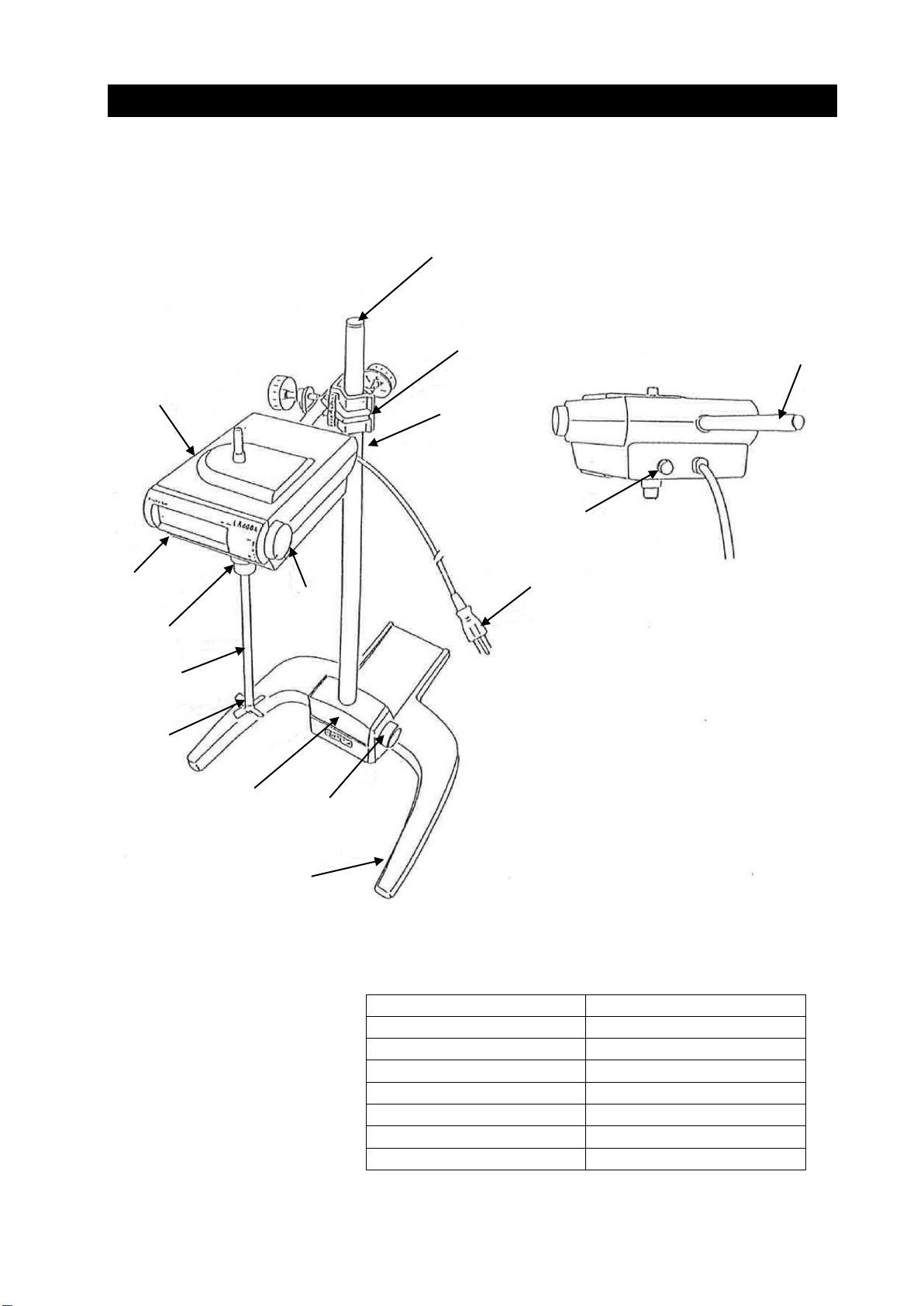

1. Confirm the packing contents.

Main body: 1 unit

Shaft: 1 pc.

Stirring propeller 1 pc.

φ75mm (LR500 series)

Chunk handle: 1 pc.

Clamp: 1 pc.

Fuse: 1 pc.

Delivery date plate: 1 pc.

Guarantee certificate: 1 copy

Instruction manual: 1 copy

2. Assemble according to the external view.

2.1. (Optional accessory, frame)

Put the support ①in the support fixing boss ④, then fix it firmly with the tightening

knob③.

2.2. Attach the clamp ⑧to the frame support ①, then fix the main body ⑥

.

2.3. Screw the stirring propeller ⑩into the stirring shaft ⑨, and insert the stirring shaft ⑨into the

chuck ⑪, then fix it so as fastening at three chuck holes to be equal by the chuck handle.

Choose a receptacle with grounding connectors not to get electric shock. If there are only

bipolar receptacle available in your workshop, connect an optional grounding adapter to the

oven’s power plug, and connect the adapter’s grounding wire to a receptacle’s grounding

terminal.

Don’t connect the grounding wire to gas or water piping.

Don’t use branching plug socket, which causes heat generation of the power line.

Don’t install the LABO-STIRRER in the place where inflammable gas or corrosive gas is

generated.