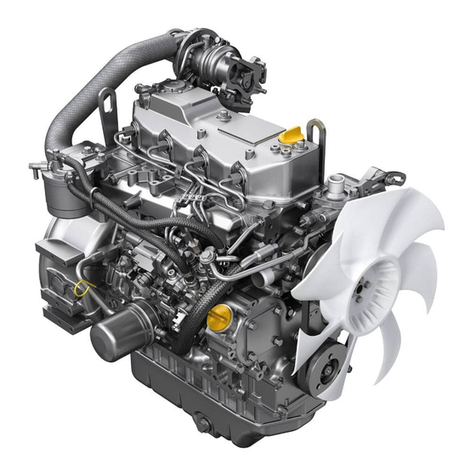

INTRODUCTION

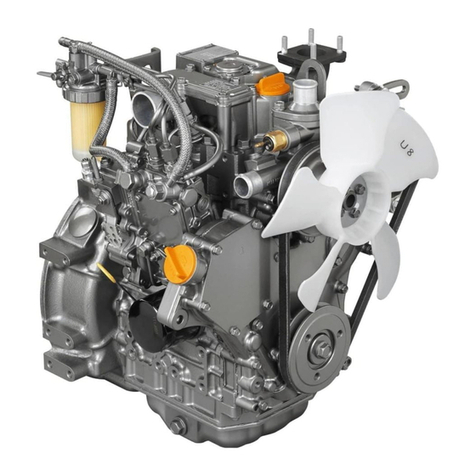

Welcome to the world of Yanmar Marine!

Yanmar Marine offers engines, drive

systems and accessories for all types of

boats, from runabouts to sailboats, and from

cruisers to mega yachts. In marine leisure

boating, the worldwide reputation of Yanmar

Marine is second to none. We design our

engines to respect nature. This means

quieter engines, with minimal vibrations,

cleaner than ever. All of our engines meet

applicable regulations, including emissions,

at the time of manufacture.

To help you enjoy your Yanmar 6LPA series

engine for many years to come, please

follow these recommendations:

• Read and understand this Operation

Manual before you operate the engine to

ensure that you follow safe operating

practices and maintenance procedures.

• Keep this Operation Manual in a

convenient place for easy access.

• If this Operation Manual is lost or

damaged, order a new one from your

authorized Yanmar Marine dealer or

distributor.

• Make sure this manual is transferred to

subsequent owners. This manual should

be considered a permanent part of the

engine and remain with it.

• Constant efforts are made to improve the

quality and performance of Yanmar

products, so some details included in this

Operation Manual may differ slightly from

your engine. If you have any questions

about these differences, please contact

your authorized Yanmar Marine dealer or

distributor.

• The specifications and components

(instrument panel, fuel tank, etc.)

described in this manual may differ from

ones installed on your vessel. Please refer

to the manual provided by the

manufacturer of these components.

• Refer to the Yanmar Limited Warranty

Handbook for a complete warranty

description.

6LPA Series Operation Manual 1

© 2007 Yanmar Marine International