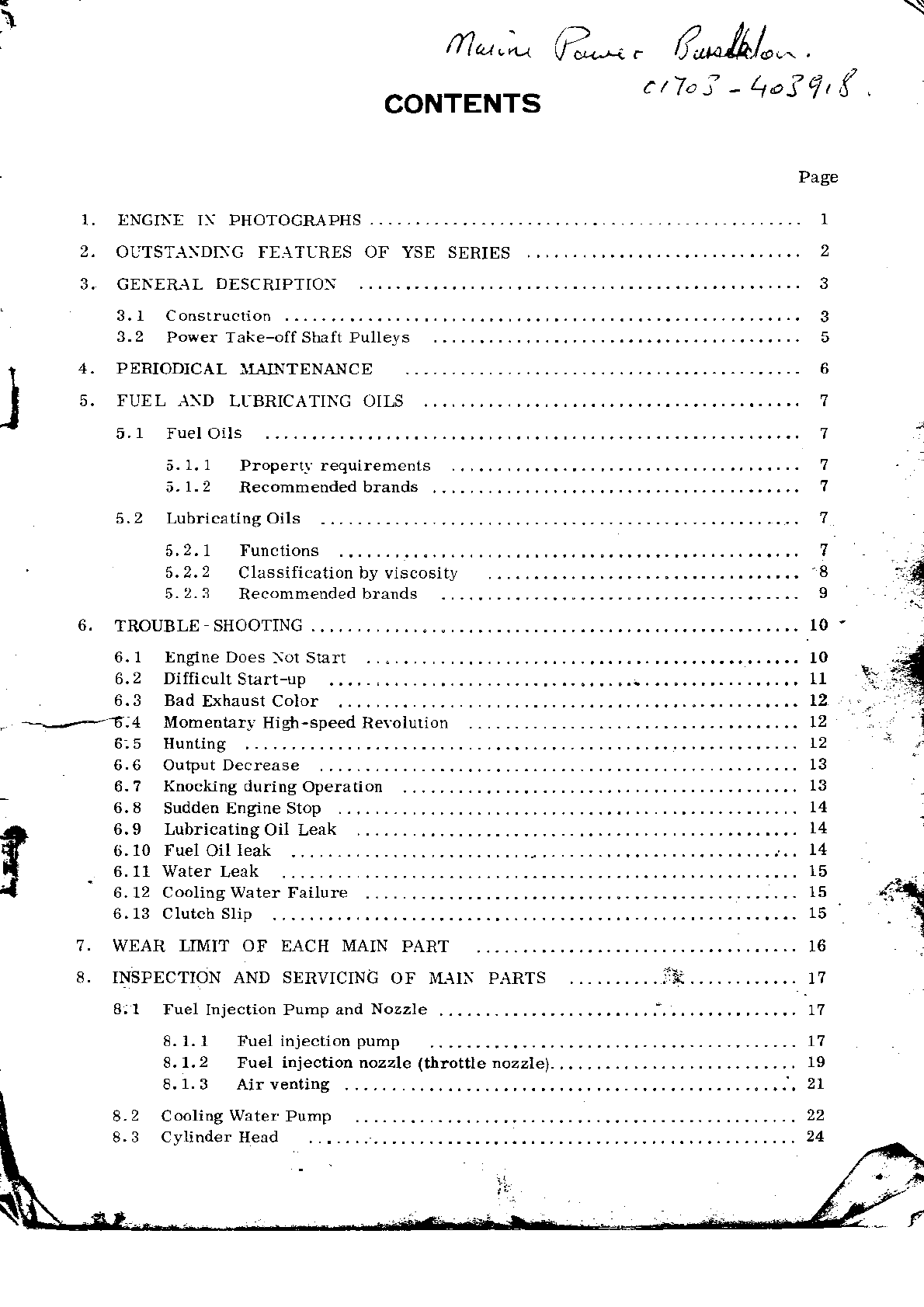

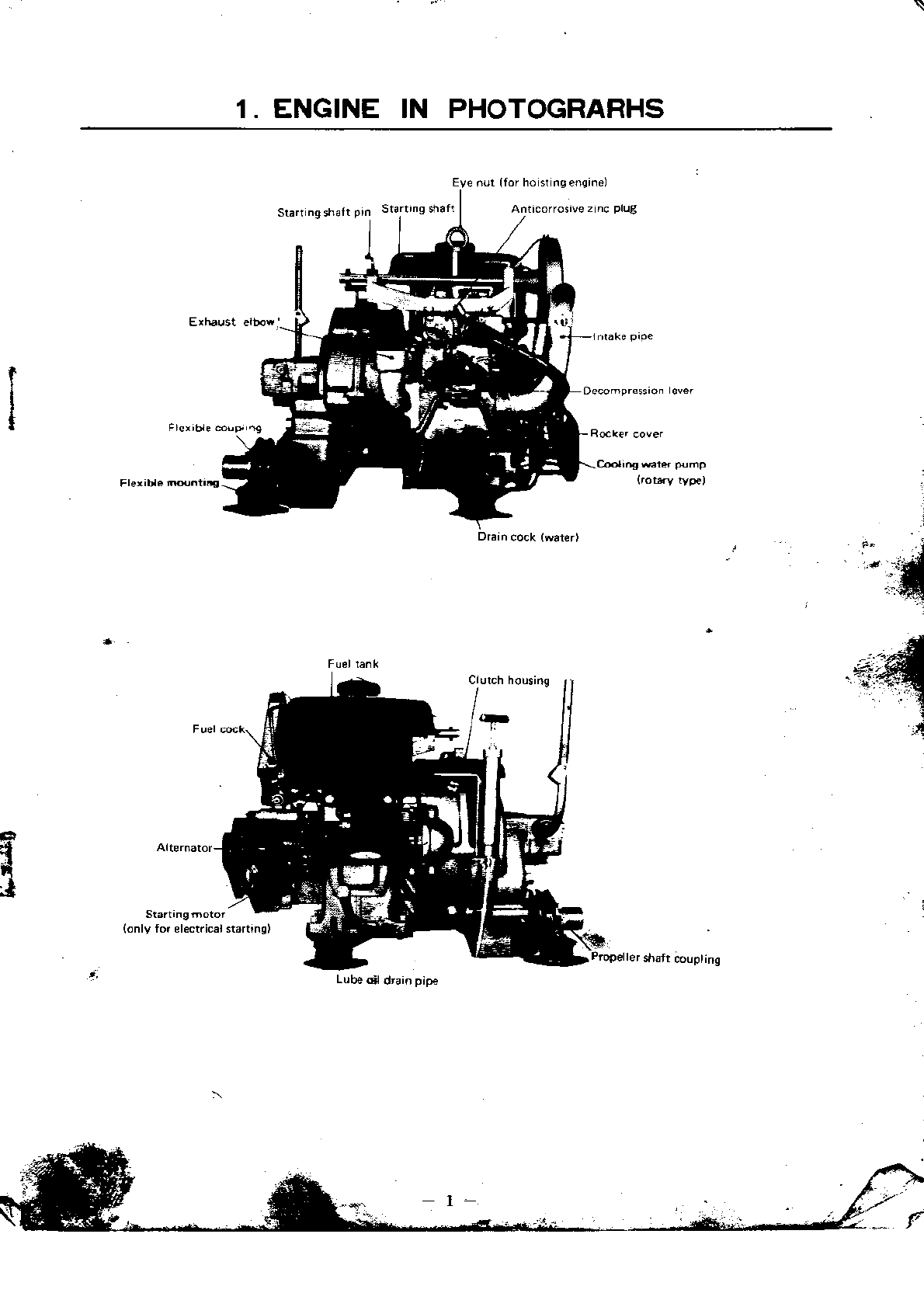

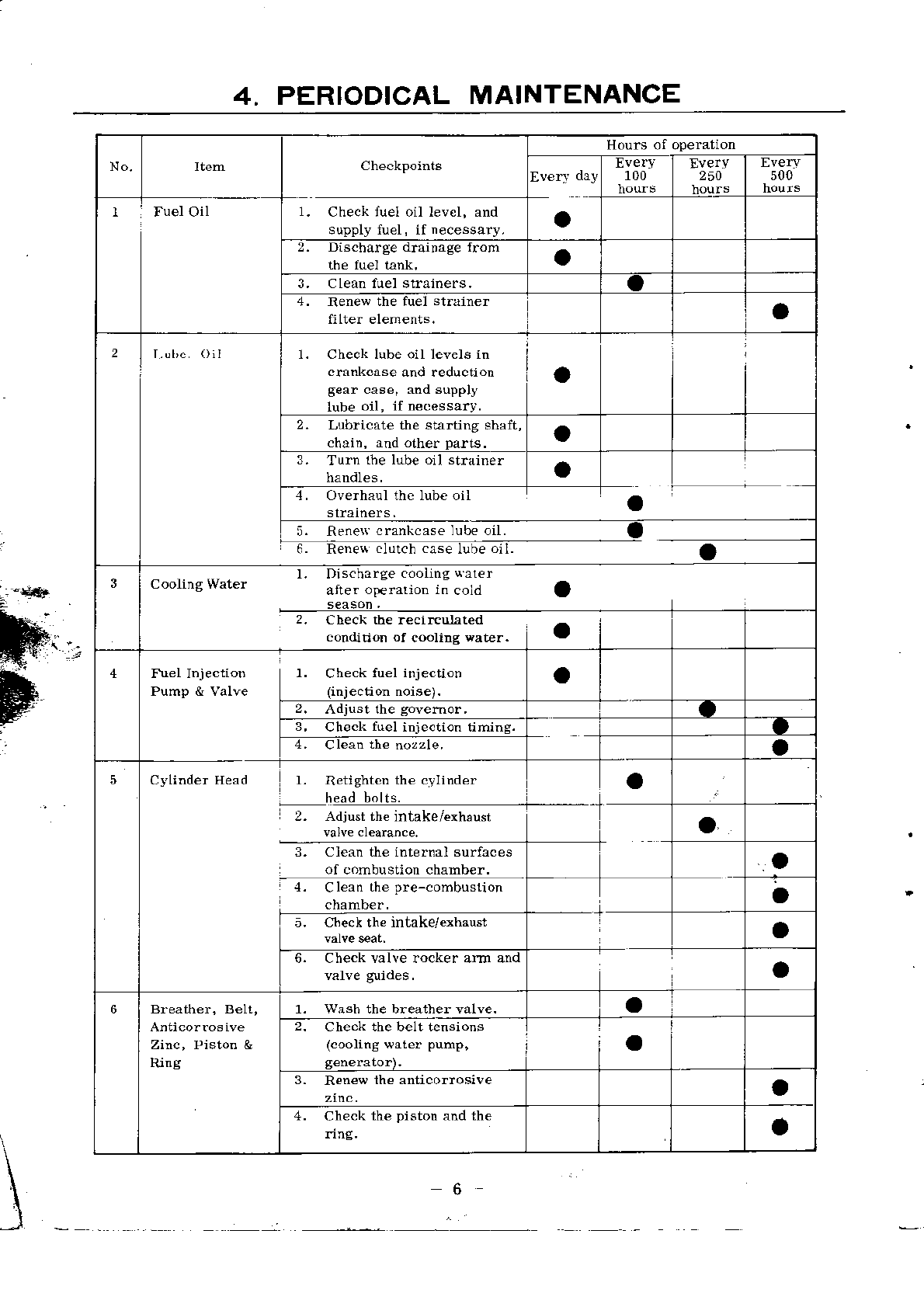

Yanmar YSE8 User manual

Other Yanmar Engine manuals

Yanmar

Yanmar 6CX530 User manual

Yanmar

Yanmar 6LY3-STC User manual

Yanmar

Yanmar 3YM20 User manual

Yanmar

Yanmar 2QM15 User manual

Yanmar

Yanmar 1GM10 Install guide

Yanmar

Yanmar 4BY2 Installation manual

Yanmar

Yanmar 1GM User manual

Yanmar

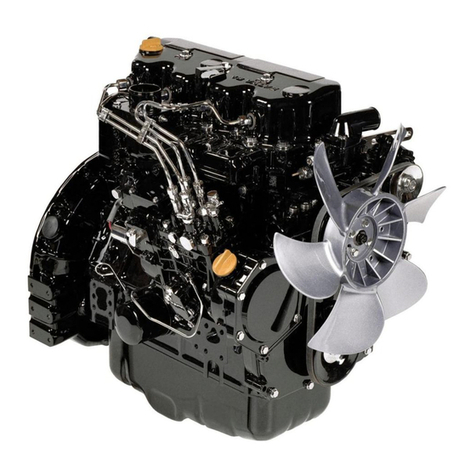

Yanmar 4TNV98T-ZGGE User manual

Yanmar

Yanmar 3YM30 User manual

Yanmar

Yanmar 2TNV70 User manual

Yanmar

Yanmar 4BY3-150 User manual

Yanmar

Yanmar 3TNV82A User manual

Yanmar

Yanmar 3TNV Series User manual

Yanmar

Yanmar 4JH4-TE User manual

Yanmar

Yanmar 4JH45 User manual

Yanmar

Yanmar 2YM15 User manual

Yanmar

Yanmar D10 Guide

Yanmar

Yanmar 3TNV88-BGGE User manual

Yanmar

Yanmar L48V User manual

Yanmar

Yanmar 3JH4E User manual