4

Indicator will act according to instruction from computer,

please refer to following notes and table:

AD: address of indicator (example A in ASCII code 41);

NN: address of memory pc wants to read/write;

C1: Content pc wants to read/write (000 digit);

C2: Content pc wants to read/write (00 digit);

C3: Content pc wants to read/writ (0 digit);

XH: Verify result for high 4 digits;

XL: Verify result for low 4 digits;

Notes:

•Address indicator could set is from 1~26, while

communication address is corresponding from A~Z;

•Instruction from A~Z is transferred in ASCII code;

but the example listed in table is in Hex. code. When

communicating with PC via the hyper terminal software(This

software is with windows operating system),you should

choose “transmit in hex format”, or else you must convert

the example to ASCII code;

•Instruction Q,R,S,T U is read/write operation for

data memory. There are many strings in data memory, but

one instruction from pc only triggers one operation, hence

several instructions should be sent from pc one by one

to do these operations

Instruction table is listed in appendix

•Connect indictor to scoreboard via 20mA current

loop output;

Data is transmitted serially in binary code with baud rate 600.

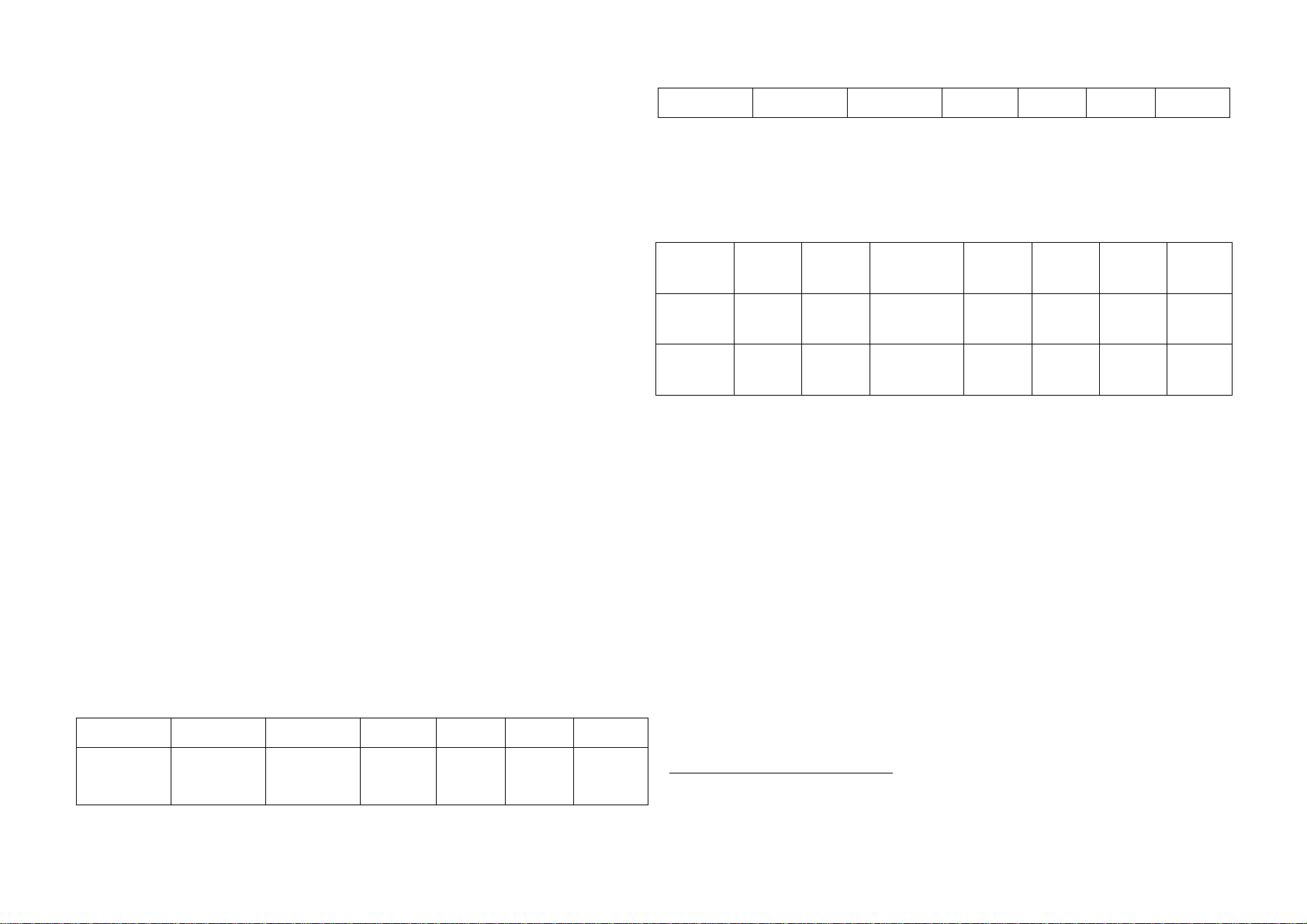

Data format is as listed below (one group):

0 1 2 3 4 5 6 7 8 9 10

START DATA(Low is prior to high) SIGN STOP

Indicator sends one frame data to scoreboard per 100ms, one

frame consists of 3 groups while the data format of one group

is as listed above. Below is the content for one frame:

0 1 2 3 4 5 6 7 8 9 10

D0 D1 D2 D3 D4 D5 D6 D7 SIGN STOP

roup

1 Start X Y G16 G17 0 1

0 1 2 3 4 5 6 7 8 9 10

D0 D1 D2 D3 D4 D5 D6 D7 SIGN STOP

roup

2 Start G8 G9 G10 G11 G12 G13 G14 G15 0 1

0 1 2 3 4 5 6 7 8 9 10

D0 D1 D2 D3 D4 D5 D6 D7 SIGN STOP

roup

3 Start G0 G1 G2 G3 G4 G5 G6 G7 1 1

For group one, Sign bit is 0; X(D0,D1,D2)means decimal point

(0~3); Y(D3)means sign(1 for negative while 0 for positive);

Y (D4) means display weight type( 1 for net weight while 0 for

tare weight); G17 and G16 is binary code;

For group two, Sign bit is 0; G15~G8 is binary code;