YASKAWA USAREM-A5A Manual

Other YASKAWA Servo Drive manuals

YASKAWA

YASKAWA SGM7D User manual

YASKAWA

YASKAWA SGM-A3 User manual

YASKAWA

YASKAWA XtraDrive Series User manual

YASKAWA

YASKAWA E-V Series User manual

YASKAWA

YASKAWA Sigma-7 SGD7S Series User manual

YASKAWA

YASKAWA SGDV-R70F User manual

YASKAWA

YASKAWA Sigma-7-S Series User manual

YASKAWA

YASKAWA JUSP-MD D01A Series User manual

YASKAWA

YASKAWA E-V-MD Series User manual

YASKAWA

YASKAWA M Series Manual

YASKAWA

YASKAWA SERVOPACK Sigma 7W Series User manual

YASKAWA

YASKAWA S-II Plus Series User manual

YASKAWA

YASKAWA UAK series User manual

YASKAWA

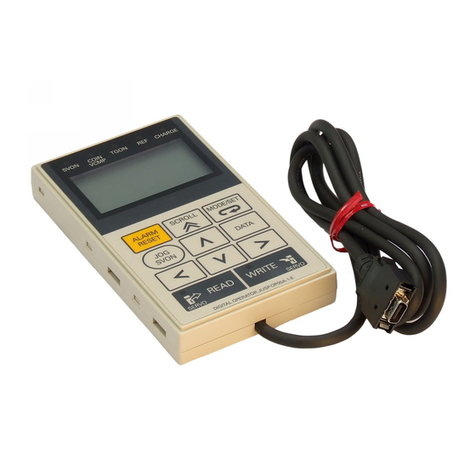

YASKAWA SGDV-OFB03A User manual

YASKAWA

YASKAWA E-III Series Installation instructions

YASKAWA

YASKAWA JUNMA SERIES User manual

YASKAWA

YASKAWA E7 Drive User manual

YASKAWA

YASKAWA SGD7S-****20A Series User manual

YASKAWA

YASKAWA E-V Series User manual

YASKAWA

YASKAWA SGD7W Series User manual

Popular Servo Drive manuals by other brands

Lenze

Lenze m850 Mounting and switch-on instructions

Baumuller

Baumuller b maXX 3000 Instruction handbook

Baumuller

Baumuller b maXX 5000 Instruction handbook

Baumuller

Baumuller b maXX 5500 Instruction handbook

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

Omron

Omron CK5M-CPU 1 Series Startup guide