Contents

1Introduction ......................................................................................................................... 4

2Getting Started .................................................................................................................... 4

2.1 Safety.............................................................................................................................. 4

2.2 What’s in the box?.......................................................................................................... 4

2.3 CNC Stylus assembly .................................................................................................... 5

3Collet system....................................................................................................................... 6

3.1 Collet sizes ..................................................................................................................... 6

3.2 Fitting and removing a collet ........................................................................................ 6

4Fitting CNC stylus ............................................................................................................... 8

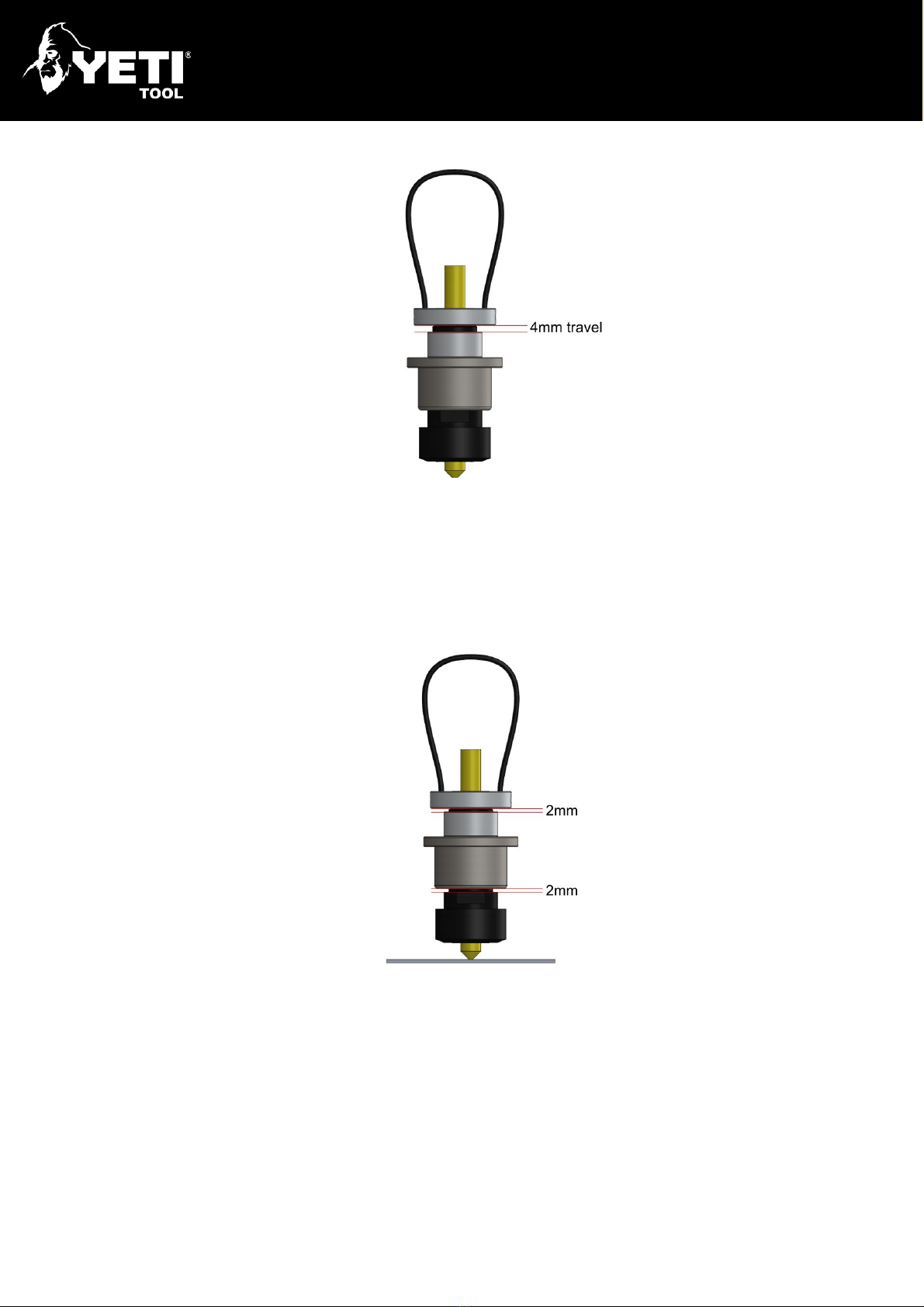

5Setting Z datum................................................................................................................... 8

6Pen plotting ....................................................................................................................... 10

6.1 Materials....................................................................................................................... 10

6.2 Preparation................................................................................................................... 10

6.2.1 Spoil board ............................................................................................................ 10

6.2.2 Work-holding ......................................................................................................... 10

6.3 Mounting a drawing device......................................................................................... 10

6.4 CAM .............................................................................................................................. 11

6.4.1 Toolpaths .............................................................................................................. 11

6.4.2 Retract height........................................................................................................ 11

7Vinyl cutting....................................................................................................................... 12

7.1 Materials....................................................................................................................... 12

7.1.1 Self-adhesive vinyl ................................................................................................ 12

7.1.2 Heat transfer vinyl ................................................................................................ 12

7.1.3 Rigid vinyl .............................................................................................................. 12

7.2 Preparation................................................................................................................... 12

7.2.1 Spoil board ............................................................................................................ 12

7.2.2 Cutting mat............................................................................................................ 12

7.2.3 Work-holding ......................................................................................................... 13

7.3 Blade types................................................................................................................... 13

7.4 Changing a blade ......................................................................................................... 14

7.5 Setting blade height..................................................................................................... 14