MACHINE OPERATION

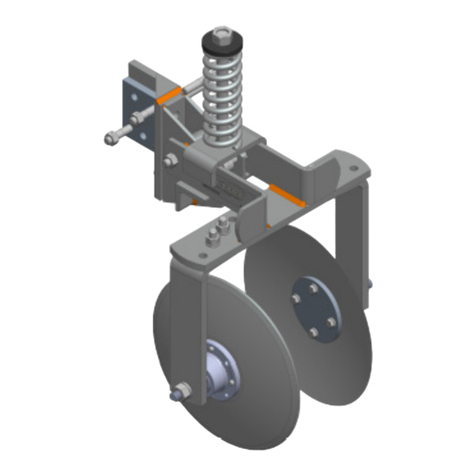

Step 1. Adjust Row Unit Depth:

Set depth (approximate) on each row unit. Adjust screw adjust knob (15/16 wrench) to achieve your preferred

depth. Adjustments can be made in ¼” increments. Rotating the screw adjust knob clockwise will raise the

gauge wheels making the units go deeper. Rotating the screw adjust knob counterclockwise will lower the gauge

wheels making the units go shallower. The depth decal on the side of each unit is only a reference & NOT an

actual depth in inches as to where the unit is set. For example, 3 does not mean 3 inches deep necessarily.

Actual depth is determined by how low the cutting coulter is below the gauge wheels. Other factors can play in to

setting the depth such as row cleaner and rolling basket settings.

Step 2. Engage Pneumatic System:

Engage the toolbar’s compressor source. Allow the compressor to engage & complete 1 full cycle before

applying pressure to any circuit. Hydraulic compressor should operate at 1,350 RPM. See operator’s manual

for adjusting hydraulic oil flow if needed. The Tank Pressure should always be above 100psi. Set all

adjustable circuits on cab control monitor to 0psi.

Step 3. Properly Set Toolbar Height & Levelness

Fully lower toolbar and measure from bottom of toolbar to ground. Proper height is 22”-26”. To adjust

toolbar height add or remove cylinder stops on main lift cylinders in center of machine. Use a bubble level

placed on main 7”x9” toolbar to insure toolbar is level front to back. To adjust levelness raise or lower front

cylinder on hitch to tractor drawbar. Once proper height and levelness are achieved the row unit parallel

linkage should be parallel to the ground or slightly downhill from front to back. Check to be sure the toolbar is

level side to side by placing bubble level on each section of 7”x9” toolbar frame. Adjust height of gauge

wheels on each wing to insure levelness across entire width of toolbar.

Step 4. Adjust Row Unit Downforce

Apply row unit down force until each unit’s ride is consistent, smooth, & correct depth is achieved. Row Unit

Downforce should never be above 100psi. Row unit down force may need re-adjusted once the row cleaner and

rolling basket are set properly. Push Row Lock down to lock pressure in circuit. To lower DF, pull regulator knob

to unlock, rotate knob counterclockwise, pull row lock knob out for 3-5seconds, push row lock knob back in.

Repeat as necessary until desired pressure is achieved & then push regulator knob in to lock. To add DF

pressure, simply pull regulator knob out, rotate clockwise to desired pressure, & push regulator knob in to lock.

Step 5. Adjust toolbar wing downforce

Once the toolbar is level and correct row unit downforce is achieved set toolbar wing downforce via knobs on

pressure gauges in center of machine. Operator observation should be utilized to insure gauge wheels on each

wing maintain contact throughout the field and toolbar remains level across entire machine.

Step 6. Adjust residue manager performance

Fine tune the row cleaners by applying up or down pressure. Push/pull knob will be pushed in to apply down

pressure and pulled out to apply up pressure. Turn down regulator knob or up regulator knob clockwise to

increase and counter clockwise to decrease pressure. Row cleaners should only be cleaning residue from the

strip & not engaging the soil.

Step 7. Adjust rolling basket performance

Once all other pressures, depths, and levelness are properly adjust then rolling basket performance may be

adjusted. Apply pressure to rolling basket to condition strip & incorporate fertilizer if applicable. Row unit

downforce may need readjusted once rolling basket is set.

Recheck depth of each row unit & adjust as needed. Check depth on each row by removing loose soil until

bottom of each strip is found. For most accurate measurement, remove residue away from the top of soil

surface next to each strip where measuring & measure from bottom of each strip to top of soil surface.