1. If the supply cord is damaged, it must be

replace by the professional person of the

manufacturer or the maintenance section

in order to avoid danger.

2. This tool must be placed on its stand

when not in use.

3. Be carefully when using the appliance in

places there are combustible materials;

Do not apply to the same place for a long

time.

4. Be aware that heat may be conducted to

distant combustible materials; Do not

leave the appliance unattended when it

is switch on.

5. This appliance is not intended for use by

persons(including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge unless

they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety;

Children should be supervised to ensure

that they do not play with the appliance.

Warning

When using this product, please abide by the

following procedures to avoid electric shock

or physical harm to the human body, and

prevent the occurrence of fire or other risks.

1. For safety reasons, unplug the power

cord after you have finished using the

product.

2. In the event of product failure, repairs must

be carried out by professionals or

manufacturer-designated personnel.

3. Failure to use parts approved or

recommended by the manufacturer may

have serious consequences.

4. After the soldering station is switched on,

its temperature can exceed 400°C. Do not

use near flammable or explosive objects.

To avoid burns, do not touch the metal part

of the soldering iron.

5. Do not leave the work area when the

soldering station is switched on.

6. The power cord must be unplugged and the

iron must be allowed to cool before

installing or replacing soldering iron parts.

7. After using the machine, the body of

machine must be allowed to cool before

packing.

8. The soldering iron should only be used for

soldering. Do not hit the soldering iron

against the work surface to remove flux

residues, as doing so may seriously

damage the soldering iron.

9. Soldering produces fumes, ensure there is

adequate ventilation.

10. Before using soldering tips, please take

measures for eye, fire and other safety

protection.

Safety Code Product Features

1. Small size, light weight, easy to carry.

2. Use the internal heating type heating core, high

efficiency.

3. 947II/947III/947W temperature adjustable

4. 947III with a power switch, when the appliance

is not in use, you can turn off the switch, safe

and energy saving.

5. The Internal use SMT double-sided board

manufacturing process, the process is neat and

the solder joint is firm.

6. The handle uses completely new environmental

protection material, safe and durable.

7. If attached with burning and soldering tips, it is

available for sculpturing on wood, bamboo,

paper, leather, gourd container and so on. It is

easy to replace the tips and convenient to carry

operation.

0 ~40°C °C

-20 ~80°C °C

0.22kg

947 I947 II 947 III

35/45/

60W 60W 60W

220~480°C

Specification parameter

Temp. range

Supply switch

Temp. adjustable

Operating

indicator lights

Weight

Operating temp.

Storage temp.

Storage humidity

No

Yes

Yes

No

No

No

Model

Power

AC220V-240V 50Hz/

AC 110V ±10%60Hz

Power supply

voltage

947 W

60W

200~

450°C

No

Yes

Yes

Yes

Yes

Yes

Operating Instructions

1. Open the soldering iron bracket, put the soldering

iron to the bracket.

2. Connect the power.

3. Turn on the supply switch, the soldering station

start heating.

4. Adjustable, set the temperature knob to the

desired temperature, when the temperature

becomes constant, the machine can be operated

normally .

5. After operation, please put the soldering iron back

to the bracket, turn off the supply switch.

For solder i ng iron tip use an d maintenan ce

Tips temperature

Overheating will weaken tips function, it should

select use in a low temperature. This tips temp.

excellent restoring force, low temp. rechargeable

soldering, to protect temp. sensitive components.

Cleaning

Regularly clean the soldering iron tips with a clean

sponge. After soldering, carbon compounds and

oxidants produced by flux residue may damage

the soldering iron tips, producing inaccurate

soldering, or reducing the thermal function of the

soldering iron tips. When the soldering iron is in

continuous use, the soldering iron tips should be

opened once a week to remove oxidants,

preventing damage and temperature reduction to

the soldering iron tips.

When Not in Use

When the soldering iron is not in use, it should not

be stored at high temperature to prevent flux

oxidation and weakening of thermal functions.

After Use

Following use, the soldering iron tips should be

wiped clean and a new tin layering applied to

prevent oxidization.

Noted: The temperature through the burning and

soldering tips is lower than that through the

normal soldering iron tips, about 80°C lower for

high temp arrange and about 40°C less for low

temp arrange(knife type is much lower due to the

length and width).

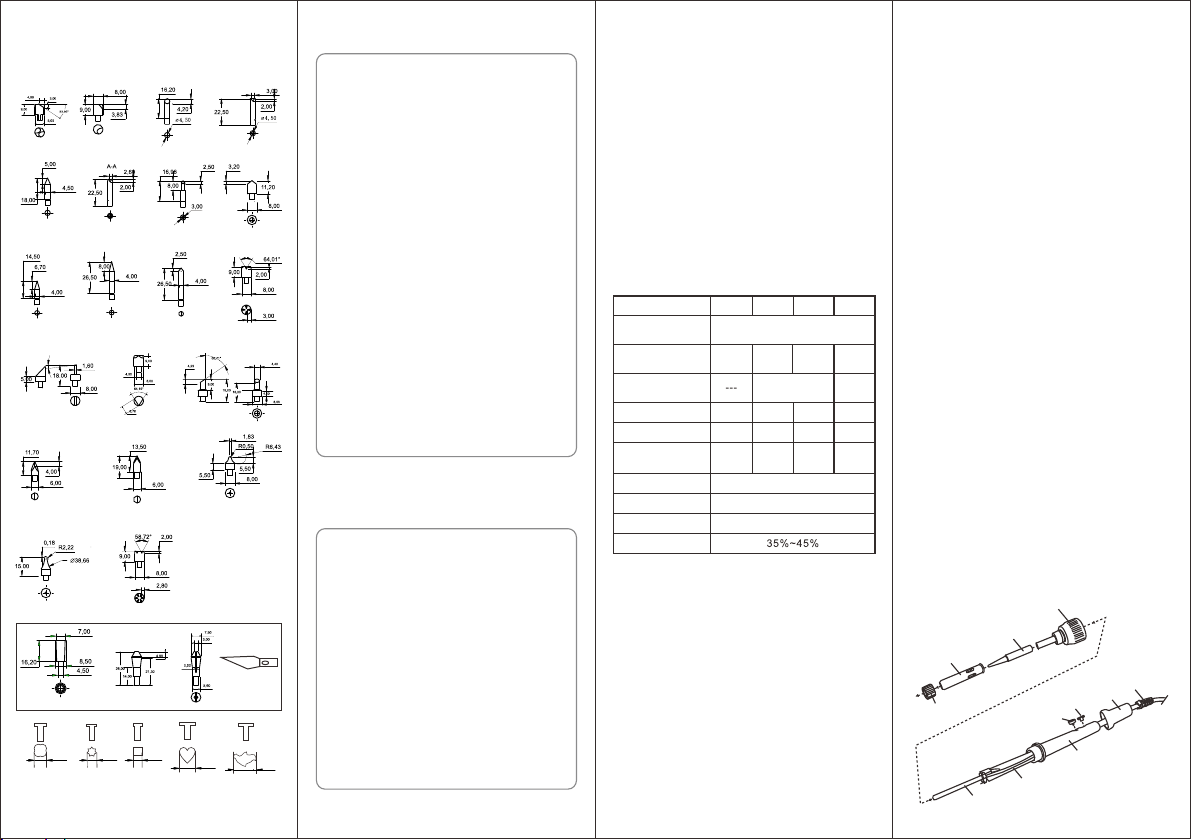

Parts Replacement

1. Replace soldering iron tips: Screwed out of

the nut, then take out the steel pipe, you can

replace the iron tips.

2. Replace the soldering iron heating core:

Screwed out the screw head, pull out the end of

line, pull out the switch/temperature adjustment

knob of the handle shell (this step can ignore if

don’t have this accessory), pull out the heating

core and the circuit board in the heating core

direction carefully.

3. The soldering iron heating core weld from the

circuit board, then replace the new heating core,

install well can be finished. Pay attention to the

method of installing soldering iron heating core.

Thread head

Soldering Iron tip

Steel pipe

Nut

End of line

Silicone case

Switch

Temperature

adjustment knob

Handle shell

Circuit board

Heating core

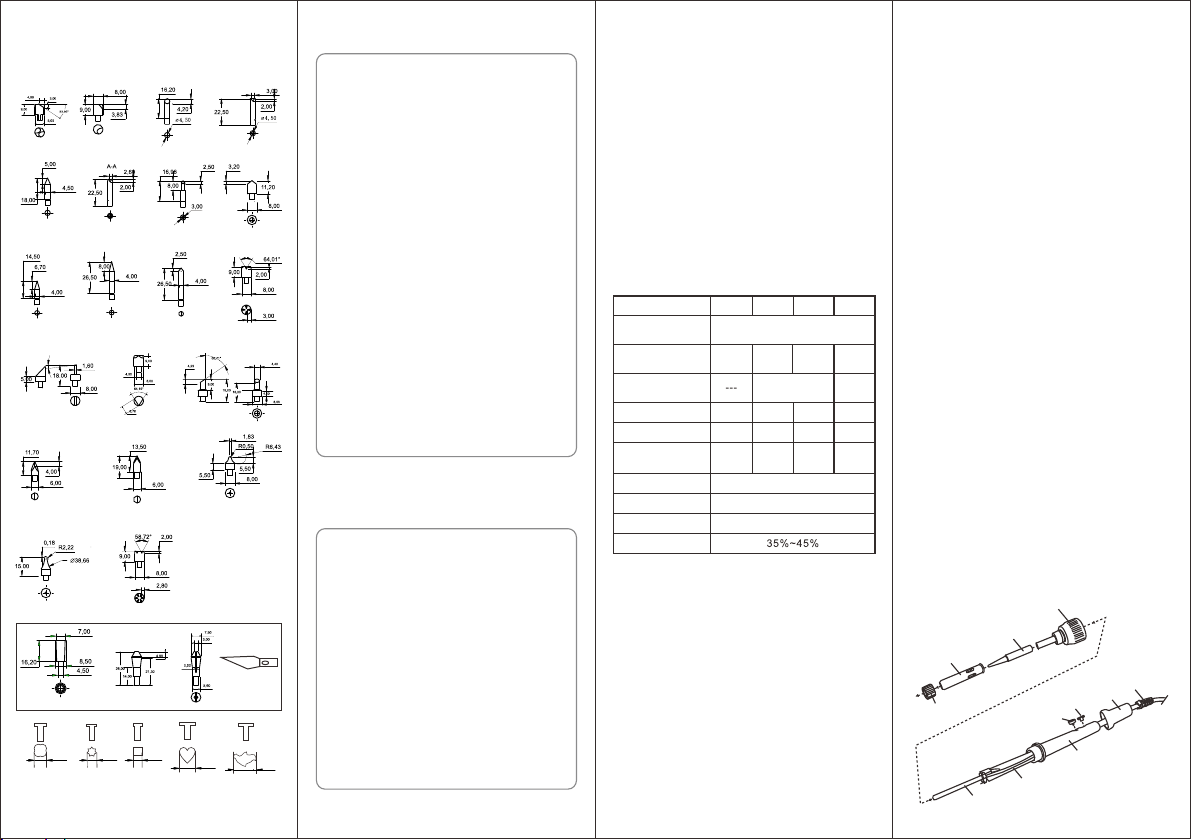

65 74

烙画烙铁咀型号图

2圆斜 1圆斜

4.5mm斜头 4.5x22.5mm凹头

4.5x23mm尖头 4.5x23mm斜边凹头 4.5mm⻢蹄 45斜⾯

4x20mm尖头 4x32mm尖头 4x32mm⻆头 4梅花

三⻆旗 V字

6mm斜⼑ 6mm⻓斜⼑

⻓枪

弧锥型

弧锥型短

六⻆花

刻⼑

双边圆

烙画锁

9.0 7.06.0

11.011.0

梅花异形 七⻆异形 四⽅异形 ⼼形异形 ⻦形异形