Use the machine, the following basic measures should abide, avoid electric

shock or cause injury or damage caused by fires.

1. To ensure personal safety, after the machine completed work, please turn

off the main power switch, and unplug the power cord if long time no use.

2. To ensure personal safety, you must use the original approval or recomm-

endation of the parts, otherwise it will lead to serious consequences.

3. Machine failure must be by professionals or the company designated per-

sonnel for repair.

4. This product is grounded three-wire plug,must be inserted within the thre-

ehole grounded outlet, do not change the plugs or use ungrounded three

adapter made it bad grounded.

5. Hot air gun or soldering station is open, its temperature are likely to reach

400 degrees. Do not use it near flammable gas, objects. Tube and the he-

at emitted very hot, can burn the body, do not touch the hot pipe and direct

injection to heat the human body.

6. Before hot air gun turned on, please ensure it is in safety environment, do

not leave the jobs site.

7. When the hot air gun opening do not install nozzle, the heat pipe and the

nozzle must be cooling. Then installed the other nozzle.

8. Please keep inlet and outlet air flow, don’t have obstruction.

9. After used, remember that the cooling body, the handle should be released

into the handle frame, then shut down the machine to sleep.

10. Do not use a soldering iron to weld outside the work; Do not iron percussi-

on table to clear the residual flux, this could seriously damage the iron.

11. The machine welding will take smoke, please do proper ventilation.

7

I. Product Features

852/902 Series

1. Use traditional high-precision thermocouple temperature measuring circuit,

dual operational amplifier controls to ensure work stability, large power, heat-

ing quickly, the temperature accuracy and stability, without the air flow influe-

nce, the real lead-free desoldering.

2. Air gun heater using the latest technology(skeleton type), high-quality heater

production, significantly improved the stability and reliability and significantly

improve avoid to shocking and anti-strike ( traditional techniques use quartz

glass, can not afford to drop and re-shock, in the transport and use of the pro-

cess is very easy to damage), and working life is much longer than the traditi-

onal type.

3. the air gun heater using new technology to make air gun’s outlet Meanwhile

wind way. The diaphragm pump and brushes fan are two ways the perfect co-

mbination of wind, when using a large nozzle a spiral air flow for the soft wind,

when using a small nozzle, the air flow is strong rotating winds, and air flow is

adjustable to accommodate a variety of purposes.

4. The handle ( Brushless fan model ) equipped with a sensor switch, as long as

we grip the handle, the system can quickly enter working mode; handle back

into the handle frame, the system will enter standby mode, easy to operate in

real time, meanwhile can extend heater life.

5. Use brushless fan/diaphragm pump as the air source,extremely long life, low-

oise.

6. The iron part use high quality heating element, rapid heating and long service

life; Antistatic design, to prevent electrostatic damage to the delicate SMD

components.

8

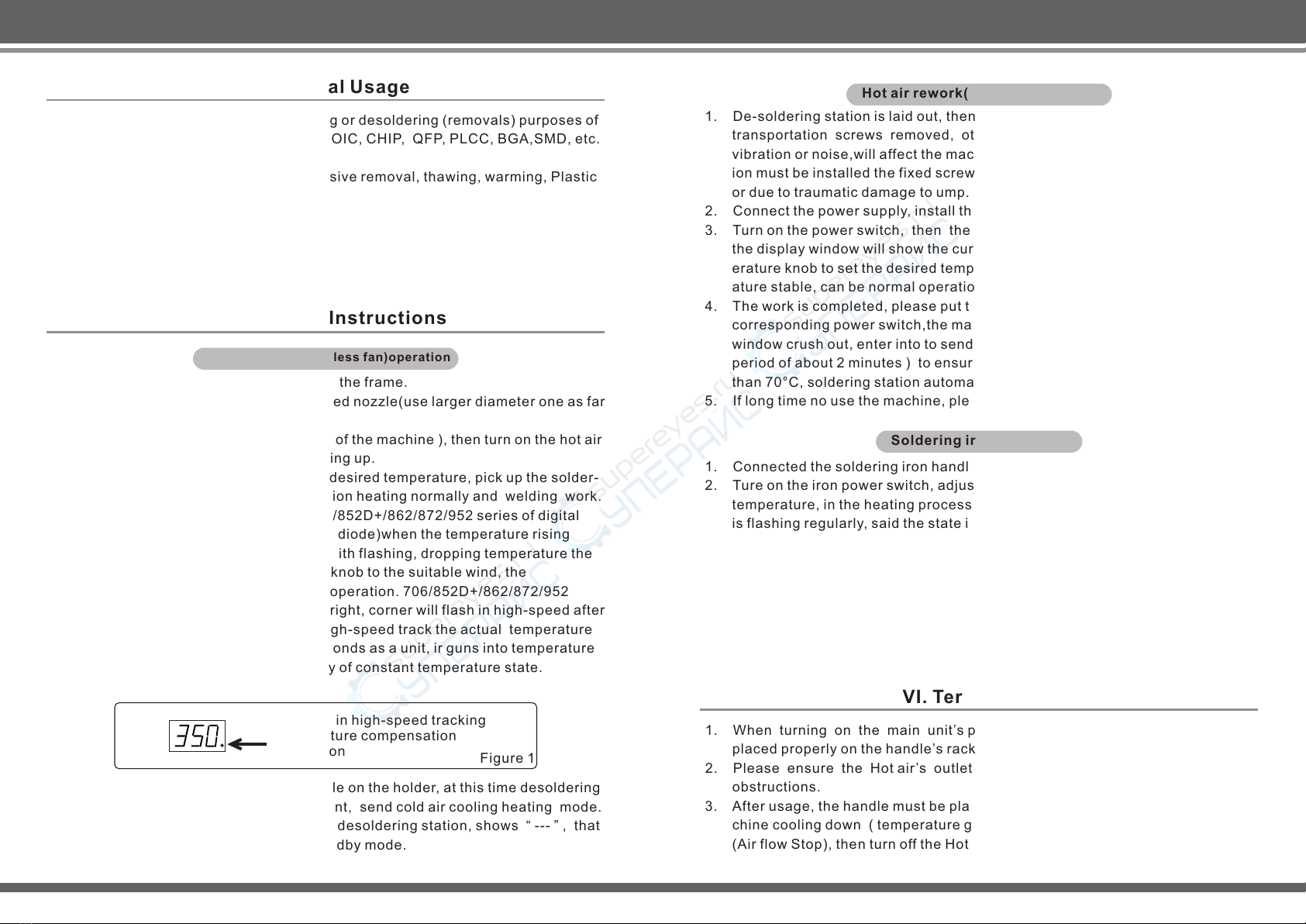

706/852D+/862/872/952 Series

1. 706/852D+/862/872/952 Series Integrate all merits of 852 series, use the

newest microcomputer processor PID program control technology, the precise

digital show air gun and the iron temperature, the power is larger, the elevation

of te-mperature is rapidly, it won’t influenced by the air output, it is realized

lead-free desoldering. The procedure tracks the air gun and the iron actual

temperature by highly speed take the millisecond as the unit , the mysterious

temperature compensation speed strengthen the temperature stability, the

temperature static error has been small, temperature compensation is very

quickly , which could adapt each kind of adverse circumstance.

1. If the supply cord is damaged, it must be replaced by a special cord or

assemble available from the manufacturer or its service agent.

2. WARNING: This tool must be placed on its stand when not in use.

3. Be careful when using the appliance in places where there are

combustible materials;

Do not apply to the same place for a long time.

4. Be aware that heat may be conducted to combustible materials that are

out of sight; Do not leave the appliance unattended when it is switched on.

5. This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge. Unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

6. Air pump type:

Before shipment please be sure fix screw at the bottom of the machine (

M5*20 white), otherwise it will cause serious problem. Before using

please remove the screw(M5*20 white) at the bottom of the machine,

otherwise it will cause serious problem.

Warning!!!

Safety Rules