Ylmaz PVCveAlm. İşleme MakineleriLtd.Ştd

TurgutÖzalBulvar No173Taşdelen34788

Çekmeköy/ ISTANBUL-TÜRKİYE

Tel: 0090216 312 28 28 Pbx

Fax: 00900216 484 42 88

e-mail yilmaz@yilmazmachine.com.tr

web http://www.yilmazmachine.com.tr

1.GENERALINFORMATION

1.1.INTRODUCTION

Theuser’smanualgivenbythemanufacturercontains necessaryinformationaboutthemachineparts.Eachmachine

operatorshouldreadtheseinstructionscarefully,andthemachineshouldbeoperatedafterfullyunderstanding them.

Safeandefficientuseofthemachineforlongtermdependsonunderstanding andfollowing theinstructionscontained

inthismanual.Thetechnicaldrawingsanddetailscontainedinthismanualconstituteaguidefortheoperator.

1.2.MANUFACTURER

*IncaseofanytechnicalproblempleasecontactyournearestYILMAZdealer,orYILMAZheadoffice through the

abovementionedphone, faxore-mailaddress.

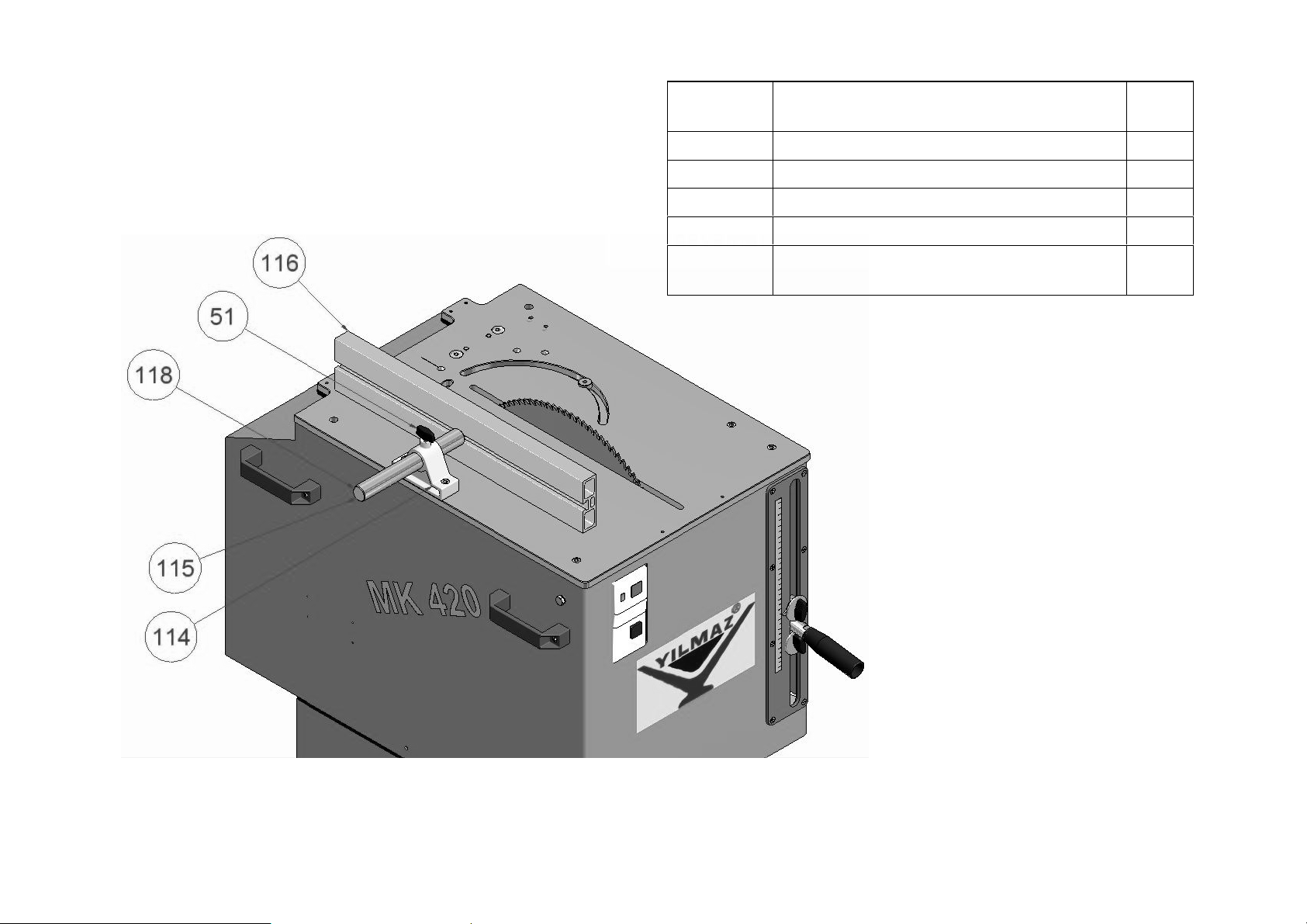

*Technicallabelswiththemodeldescriptionofthemachinearefixedontothefrontsideofeachmachine.

*Themachine’sserialnumberandmanufacturing yeararestipulatedonthetechnicallabel.

Averagelifeusageofproductionis10years. Ifyouhaveanyfurtherfailure andcomplaint,pleaseinformto

ourbelowmentionedtechnicalservice byverbalorwritten