2IM 77M02B11-01EN 3rd Edition Apr. 01, 2022-00

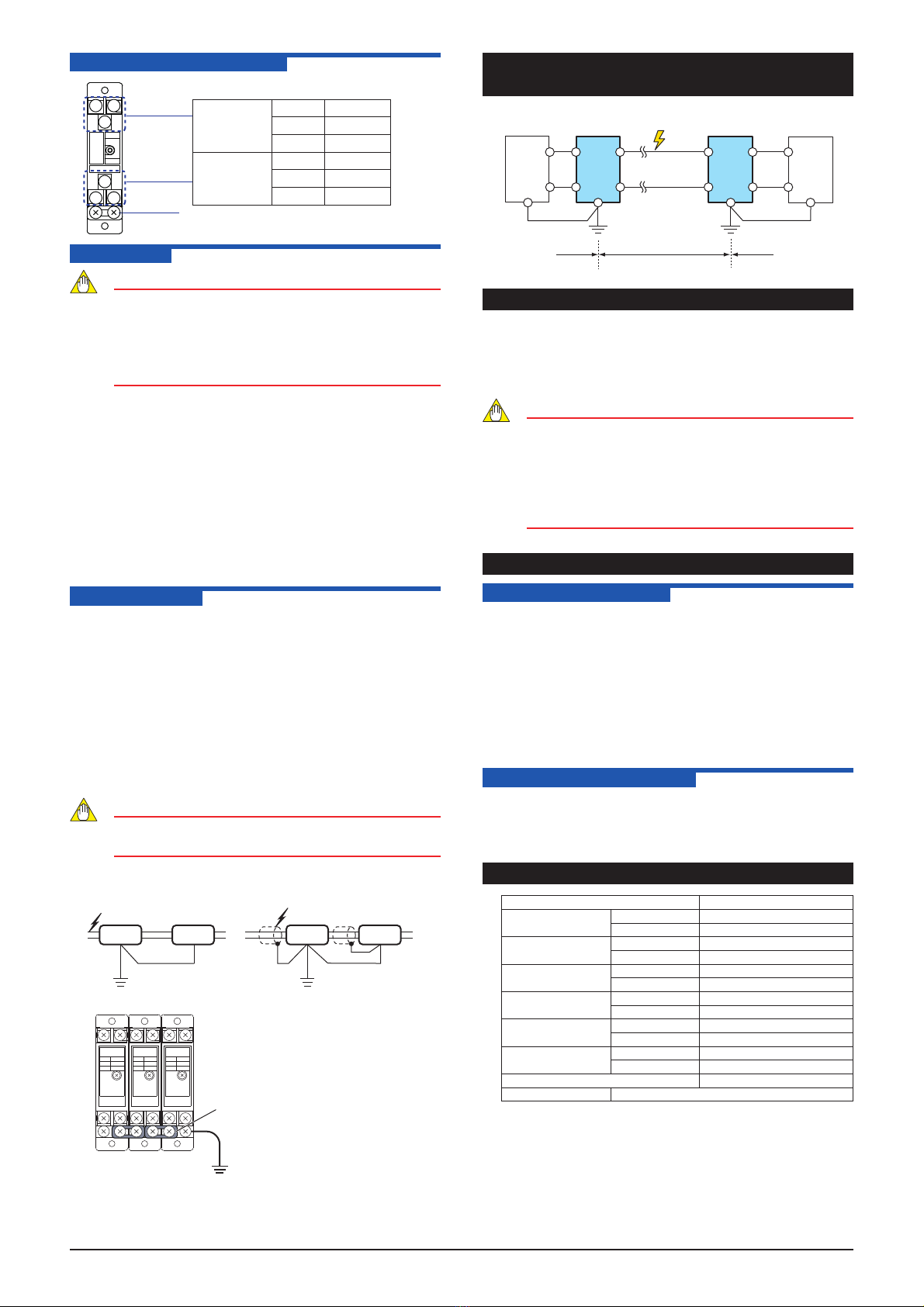

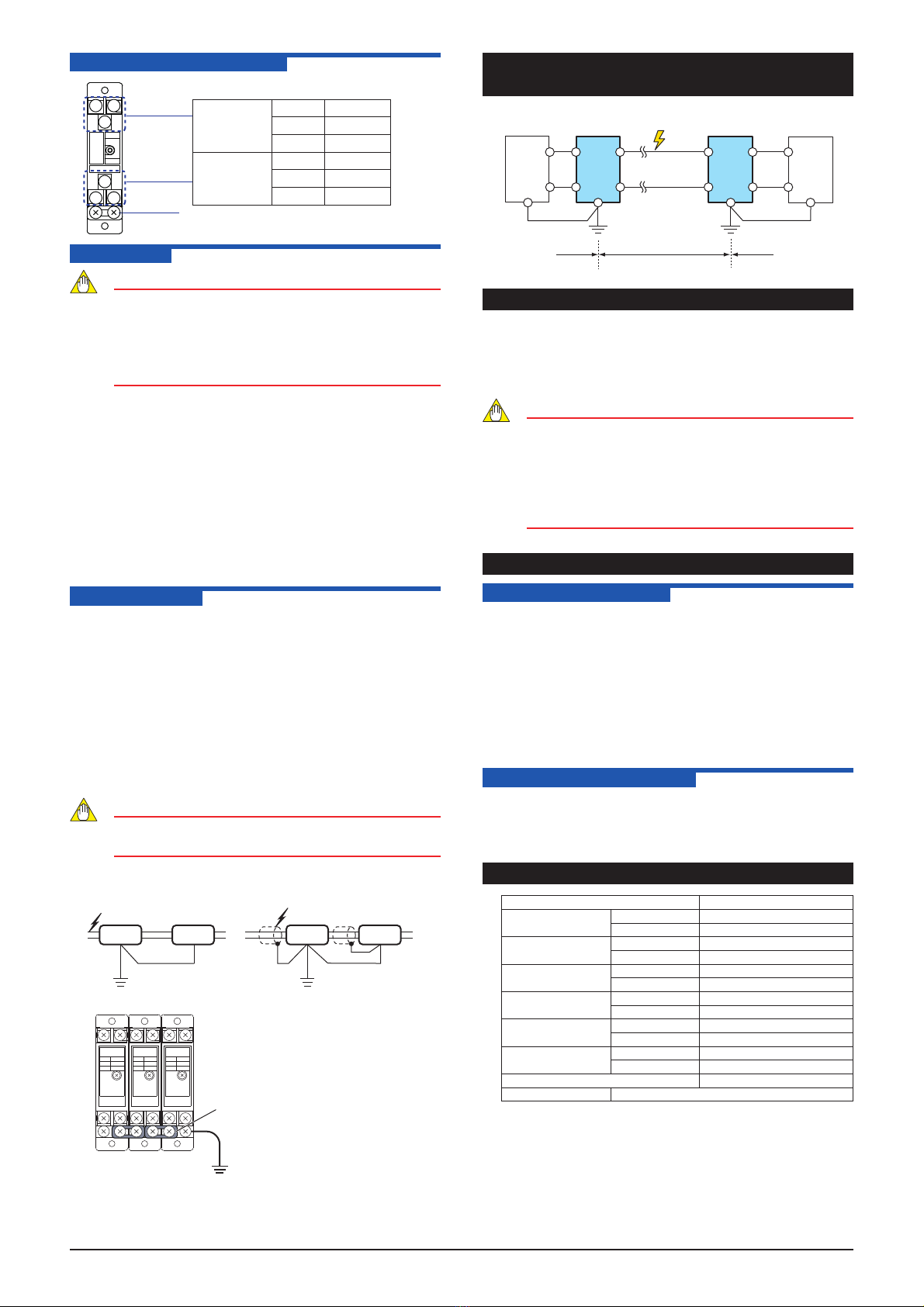

1.3 Terminal Arrangement

Protect-side

terminal

Surge-side

terminal

A

B

C

1

2

3

+

í

Not Connected

+

í

Not Connected

Grounding

terminal

A

C

B

12

3

1.4 Wiring

NOTE

Use of arresters ignoring the specifications may cause

electric shock, overheating or damage.

1. Input signal value applied to the arrester should

meet the required specifications.

2. The external wiring to the terminals and wiring to

ground are as specifications.

Flexible twisted wire and durable round crimp-on terminal (JIS C

2805) are recommended to use.

(1) Signal cable

Nominal cross-sectional area of conductor: 0.5 to 0.75 mm2.

Example of suitable cable: Vinyl code (VJF) (JIS C 3306) for

electronic instrument.

(2) Grounding cables

Nominal cross-sectional area of conductor: 2.0 mm2or more

for grounding.

Example of suitable cable: 600V vinyl insulated cable (IV)

(JIS C 3307), Vinyl insulated cable

(KIV) (JIS C 3316) for electronic

instrument

1.5 Grounding

Interconnect the ground terminals of the arrester and the

instrument to be protected. Touch ground from the arreter side

as shown in the figure below. Install the arrester and instrument

as close as possible, and make the cable as short as possible.

The wires for interconnect grounding should have lower effective

resistance than ground resistance.

• Make sure to earth ground the ground terminal through

minimum resistance.

• The grounding method must comply with the grounding

system defined by rules and standards of the country or the

region.

It also should meet the grounding requirements of the

instrument to be protected.

NOTE

Wire tightening torque for arrester should not be 1.2

N•m or more.

(1)

Interconnect Grounding

(2)

Interconnect Grounding

(when using shield line)

Arrester

Instrument

Arrester

Instrument

Apply the grounding system which is

defined by the rules and standards

of the country or the region.

Short bar

(for grounding terminal connection)

Grounding for serial installation of

arresters is to connect grounding

terminals of neighboring arresters to

each other and touch ground at one

point from last arrester according.

Make sure to earth ground the ground terminal through minimum resistance.

2. CONNECTION OF ARRESTERS WITH

INSTRUMENTS TO BE PROTECTED

Pulse

Generator

Pulse Signal

Convertor

AR-LP AR-LP

A

B

1

2

1

2

A

BGND

Ground Terminal Ground Terminal

Protect side Protect side

Surge side

Lightning

Surge

+

í

3. ENVIRONMENTAL CONDITIONS

Ambient temperature: −10 to +60°C

Relative humidity: 5 to 90% RH (No condensation)

Altitude at installation site: Max. 2000 m above sea level

Installation category based on IEC/EN61010-1: II, pollution

degree: 2 (see Note.)

NOTE

The “Installation Category” implies the regulation for

impulse withstand voltage. It is also called the

“Overvoltage category”.“ II ” applies to electrical

equipment.“Pollution level” describes the degree

to which a solid, liquid or gas which deteriorates

dielectric strength is adhering.“2” applies to a normal

indoor atmosphere.

4. MANTENABCE

4.1 Arrester Checking

The arrester main body and terminal base are connected by plug-

in. Circuit between surge side and protect side would not be open

even if the main body is removed from the socket on terminal

base by loosing main unit-fixing screw. To check the arrester

performance, remove the main body from the socket and check

it by using the AR2-CK (arrester checker: option). If the arrester

cannot be used because the main body is deteriorated or broken,

be sure to replace both the main body and the terminal block.

The terminal block may be damaged by receiving surges. The

replacement of only the main body may fail to meet its protection

performance level.

4.2 Arrester check period

To protect the instrument from damage by induced lightning, the

arrester should be checked periodically at least once a year. In

areas where lightning occurs frequently, check should be done

more often particularly after thunderstorms.

5. HARDWARE SPECIFICATION

Use 2-wire System Pulse Signal

*

Maximum continuous

operating voltage (Uc)

Between lines 50 V DC

Between ground 50 V DC

Permissible current

leakage

Between lines 10 μA or less (at 50 V DC)

Between ground 10 μA or less (at 50 V DC)

Instrument side voltage

limit (10 kV, 1.2/50 μA)

Between lines 90 V or less

Between ground 250 V or less

*Voltage protection

level (Up)

Between lines 350 V or less

Between ground 350 V or less

*Impulse durability

(8/20 μA)

Category C1 500 A

Category C2 5000 A

Discharge starting

voltage

Between lines 74 V DC or more

Between ground 74 V DC or more

*Rated current 2 A DC

JIS compliant JIS C 5381-21 (Category: C1, C2)

*: Description compliant with JIS C 5381-21.