v

IM 12B07N01-01E

<CONTENTS>

Model PH8HF, PH8HFF

Flow-Through Type Holder

CONTENTS

IM 12B07N01-01E 6th Edition

INTRODUCTION.............................................................................................i

For the safe use of this equipment.............................................................ii

After-sales Warranty ...................................................................................iii

1. Specications ........................................................................................... 1-1

1.1 GeneralSpecications ..................................................................................... 1-1

1.1.1 PH8HF Flow-through Type Holder .................................................... 1-1

1.1.2 PH8HFF (Explosionproof Type) ........................................................ 1-2

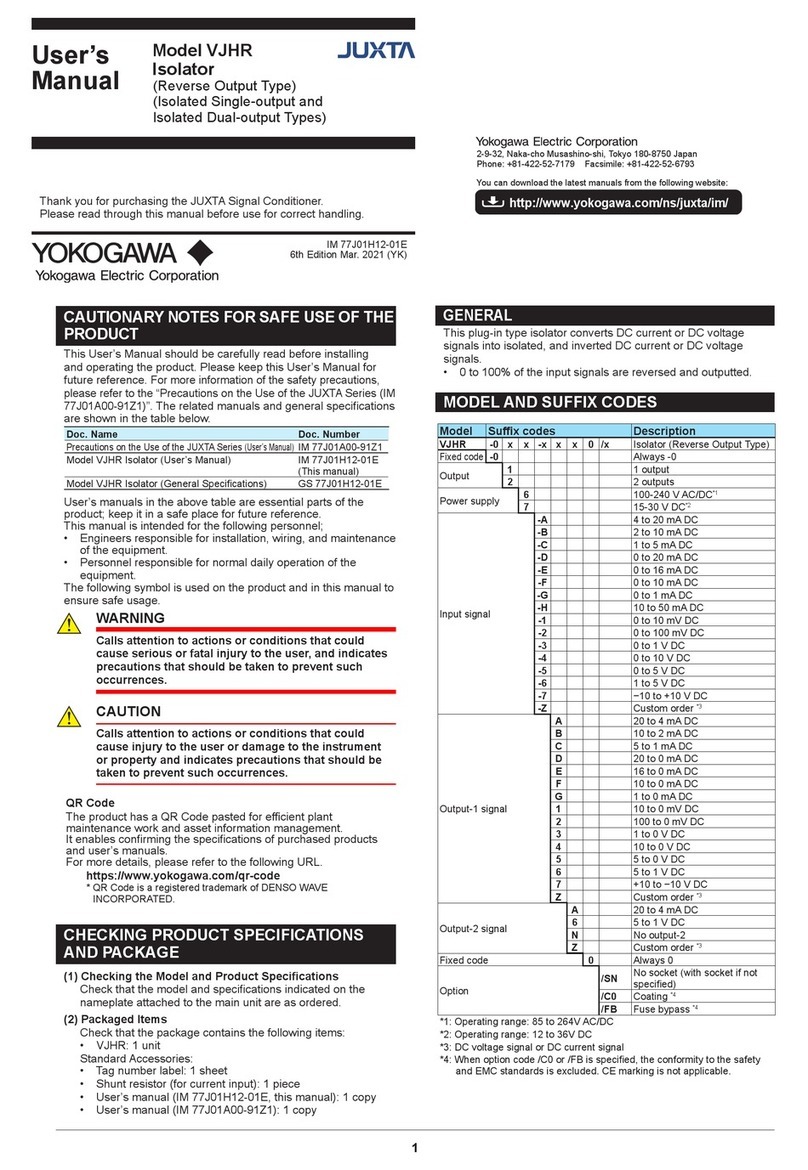

1.2 ModelandSuxcodes.................................................................................... 1-3

1.2.1 Flow-Through Type Holder PH8HF ................................................... 1-3

1.2.2 Flow-Through Type Holder (Explosionproof Type) PH8HFF ............ 1-4

1.3 ExternalDimensions ........................................................................................ 1-5

2. Installation, Piping and Wiring................................................................ 2-1

2.1 Holder Installation............................................................................................. 2-1

2.1.1 Installation Site .................................................................................. 2-1

2.1.2 Mounting the Flow-through Type Holder ........................................... 2-1

2.2 Process Piping .................................................................................................. 2-2

2.2.1 Main Precautions for Piping............................................................... 2-2

2.2.2 Piping Procedure ............................................................................... 2-4

2.3 Installing the Sensor......................................................................................... 2-5

2.4 Cleaner Piping .................................................................................................. 2-5

2.4.1 Piping Precautions ............................................................................. 2-5

2.4.2 Piping Procedure ............................................................................... 2-7

2.4.3 Installation of PH8PU1 Washer Pump and Water Tank .................... 2-8

2.5 Wiring ................................................................................................................. 2-8

2.5.1 Ultrasonic Oscillator Circuit Wiring .................................................... 2-8

2.5.2 Solenoid Valve Circuit Wiring............................................................. 2-8

2.5.3 Wiring for PH8PU1 Washer Pump and Tank..................................... 2-9

3. Maintenance/Inspection .......................................................................... 3-1

3.1 Cleaning the Holder .......................................................................................... 3-1

3.1.1 Inspecting the O-ring Seal ................................................................ 3-1

3.2 Checking the Cleaning Element...................................................................... 3-2

3.2.1 Jet Cleaning Element......................................................................... 3-2

3.2.2 Cleaning the Brush ............................................................................ 3-2