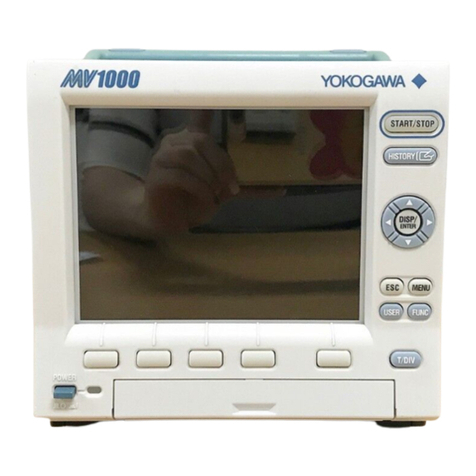

YOKOGAWA MVAdvanced MV1000 User manual

Service

Manual

Yokogawa Electric Corporation

MV1000/MV2000

SM MV1000-01E

1st Edition

i

SM MV1000-01E

Important Notice to the User

• This manual contains information for servicing YOKOGAWA’s MV1000 and MV2000.

Check the serial number to conrm that this is the correct service manual for the

instrument to be serviced. Do not use the wrong manual.

•Before any maintenance and servicing, read all safety precautions carefully.

• Only properly trained personnel may carry out the maintenance and servicing

described in this service manual.

•Do not disassemble the instrument or its parts, unless otherwise clearly permitted by

this service manual.

•Do not replace any part or assembly, unless otherwise clearly permitted by this service

manual.

•In principle, Yokogawa Electric Corporation (YOKOGAWA) does not supply parts

other than those listed in the customer maintenance parts list in this service manual

(mainly modules and assemblies). Therefore if an assembly fails, the user should

replace the whole assembly and not components within the assembly (see “Note”). If

the user attempts to repair the instrument by replacing individual components within

the assembly, YOKOGAWA assumes no responsibility for any consequences such as

defects in instrument accuracy, functionality, reliability, or user safety hazards.

•YOKOGAWA does not offer more detailed maintenance and service information than

that contained in this service manual.

•All reasonable efforts have been made to assure the accuracy of the content of

this service manual. However, there may still be errors such as clerical errors or

omissions. YOKOGAWA assumes no responsibility of any kind concerning the

accuracy or contents of this service manual, nor for the consequences of any errors.

•All rights reserved. No part of this service manual may be reproduced in any form

or by any means without the express written prior permission of YOKOGAWA. The

contents of this manual are subject to change without notice.

Note

YOKOGAWA instruments have been designed in a way that the replacement of electronic parts

can be done on an assembly (module) basis by the user. YOKOGAWA instruments have also

been designed in a way that troubleshooting and replacement of any faulty assembly can be

done easily and quickly. Therefore, YOKOGAWA strongly recommends replacing the entire

assembly over replacing parts or components within the assembly. The reasons are as follows:

• The instruments use high-performance microprocessors, large scale CMOS gate arrays,

and surface-mount components to provide state-of-the-art performance and functions.

• Repair of components can only be performed by specially trained and qualified maintenance

personnel with special highly-accurate tools, including costly ones.

• When taking the service life and cost of the instruments into consideration, the replacement

of assemblies offers the user the possibility to use YOKOGAWA instruments more effectively

and economically with a minimum in downtime.

1st Edition: April 2008 (YK)

All Rights Reserved, Copyright © 2006 Yokogawa Electric Corporation

SM MV1000-01E

ii

Trademark

• vigilantplant and MVAdvanced are registered trademarks or trademarks of Yokogawa

Electric Corporation.

•Adobe and Acrobat are registered trademarks or trademarks of Adobe Systems

Incorporated.

•Company and product names that appear in this manual are registered trademarks or

trademarks of their respective holders.

•The company and product names used in this manual are not accompanied by the

registered trademark or trademark symbols (® and ™).

Revisions

1st Edition: April 2008

iii

SM MV1000-01E

Introduction

This manual contains information for servicing YOKOGAWA’s MV1000 and MV2000.

WARNING

This service manual is to be used by properly trained personnel only. To avoid

personal injury, do not perform any servicing unless you are qualified to do

so. Refer to the safety precautions prior to performing any servicing. Even if

servicing is carried out according to this service manual, or by qualified personnel,

YOKOGAWA assumes no responsibility for any result occurring from that servicing.

Safety Standards and EMC Standards

The MV conforms to IEC safety class I (provided with terminal for protective grounding),

Installation Category II, Measurement Category II (CAT II), and EN61326 (EMC

standard), class A (use in a commercial, industrial, or business environment).

The MV is designed for indoor use.

Safety Precautions

The general safety precautions described here must be observed during all phases of

operation. If the MV is used in a manner not described in this manual, the protection

provided by the MV may be impaired. Yokogawa Electric Corporation assumes no liability

for the customer’s failure to comply with these requirements.

WARNING

• Use the Correct Power Supply

Ensure that the source voltage matches the voltage of the power supply before

turning ON the power. In the case of a desktop type, ensure that it is within the

maximum rated voltage range of the provided power cord before connecting the

power cord.

•Use the Correct Power Cord and Plug

To prevent electric shock or fire, be sure to use the power cord supplied by

YOKOGAWA. The main power plug must be plugged into an outlet with a

protective ground terminal. Do not disable this protection by using an extension

cord without protective earth grounding.

•Connect the Protective Grounding Terminal

Make sure to connect the protective grounding to prevent electric shock before

turning ON the power.

The power cord that comes with the desktop type is a three-prong type power

cord. Connect the power cord to a properly grounded three-prong outlet.

•Do Not Impair the Protective Grounding

Never cut off the internal or external protective grounding wire or disconnect the

wiring of the protective grounding terminal. Doing so invalidates the protective

functions of the instrument and poses a potential shock hazard.

•Do Not Operate with Defective Protective Grounding

Do not operate the instrument if the protective grounding might be defective.

Also, make sure to check them before operation.

SM MV1000-01E

iv

• Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors.

Operation in such an environment constitutes a safety hazard.

Prolonged use in a highly dense corrosive gas (H2S, SOx, etc.) will cause a

malfunction.

•Do Not Remove Covers

The cover should be removed by YOKOGAWA’s qualified personnel only.

Opening the cover is dangerous, because some areas inside the instrument

have high voltages.

•Ground the Instrument before Making External Connections

Connect the protective grounding before connecting to the item under

measurement or control unit.

•Damage to the Protection

Operating the instrument in a manner not described in this manual may damage

the instrument’s protection.

Safety Symbols Used on Equipment and in Manual

“Handle with care.” To avoid injury and damage to the instrument, the

operator must refer to the explanation in the manual.

Protective ground terminal

Functional ground terminal (do not use this terminal as a protective ground

terminal.)

Alternating current

ON (power)

OFF (power)

Direct current

Conventoins Used in Manual

WARNING Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and precautions that can be taken to

prevent such occurrences.

Calls attentions to actions or conditions that could cause light

injury to the user or damage to the instrument or user’s data,

and precautions that can be taken to prevent such occurrences.

CAUTION

v

SM MV1000-01E

Overview of This Manual

This manual is meant to be used by qualified personnel only. Make sure to read the

safety precautions at the beginning of this manual as well as the warnings and cautions

contained in the chapters relevant to any servicing you may be carrying out.

This manual contains the following chapters.

Chapter 1 Principles of Operation

Describes the principles of operation of the instrument.

Chapter 2 Troubleshooting

Lists problems that can occur and gives corrective actions.

Chapter 3 Testing

Gives procedures for testing the characteristics of the instrument.

Chapter 4 Adjustments

Explains how to adjust the instrument.

Chapter 5 Schematic Diagram

Provides a system conguration diagram.

Chapter 6 Customer Maintenance Parts List

Contains exploded views and a list of replaceable parts.

Chapter 7 Replacing Parts

Describes how to replace parts.

Specifications are not included in this manual. For specifications, refer to the MV1000/

MV2000 User’s Manual (IM MV1000-01E).

SM MV1000-01E

vi

Contents

Important Notice to the User..............................................................................................................i

Trademark......................................................................................................................................... ii

Revisions ..........................................................................................................................................ii

Introduction ...................................................................................................................................... iii

Safety Standards and EMC Standards............................................................................................ iii

Safety Precautions........................................................................................................................... iii

Safety Symbols Used on Equipment and in Manual........................................................................ iv

Conventuins Used in Manual...........................................................................................................iv

Overview of This Manual ..................................................................................................................v

Chapter 1 Principles of Operation

1.1 Principles of Operation ........................................................................................................ 1-1

Chapter 2 Troubleshooting

2.1 Failure Analysis Flow Chart ................................................................................................. 2-1

2.2 Troubleshooting Checklist.................................................................................................... 2-4

Chapter 3 Testing

3.1 Acceptance Test .................................................................................................................. 3-1

3.2 Self Diagnostic Test ............................................................................................................. 3-2

3.3 Performance Test................................................................................................................. 3-3

Test Environment ................................................................................................................. 3-3

Test Instruments .................................................................................................................. 3-3

Instrument Operation ........................................................................................................... 3-3

Tests .................................................................................................................................... 3-3

3.4 Test Procedures................................................................................................................... 3-4

Insulation Resistance........................................................................................................... 3-4

Protective Grounding ........................................................................................................... 3-4

Withstand Voltage................................................................................................................ 3-5

Measurement Accuracy ....................................................................................................... 3-6

Reference Junction Compensation Accuracy ...................................................................... 3-8

Battery Backup .................................................................................................................... 3-8

Pulse Input Function ............................................................................................................ 3-9

Chapter 4 Adjustments

4.1 Before Making Adjustments ................................................................................................. 4-1

Environment......................................................................................................................... 4-1

Instrument Operation ........................................................................................................... 4-1

Note ..................................................................................................................................... 4-1

4.2 Adjusting the A/D Converters............................................................................................... 4-2

Chapter 5 Schematic Diagram

5.1 Schematic Diagram (MV1000)............................................................................................. 5-1

5.2 Schematic Diagram (MV2000)............................................................................................. 5-2

vii

SM MV1000-01E

1

2

3

4

5

6

7

Contents

Chapter 6 Customer Maintenance Parts List

6.1 Customer Maintenance Parts List (MV1000)....................................................................... 6-1

6.2 Customer Maintenance Parts List (MV2000)....................................................................... 6-9

Chapter 7 Replacing Parts

7.1 Introduction .......................................................................................................................... 7-1

Replaceable Parts ............................................................................................................... 7-1

If Servicing is Required........................................................................................................ 7-1

7.2 Recommended Replacement Periods for Worn Parts......................................................... 7-2

1-1

SM MV1000-01E

Principles of Operation

1

2

3

4

5

6

7

Chapter 1 Principles of Operation

1.1 Principles of Operation

The following explains the principles of operation of the MV.

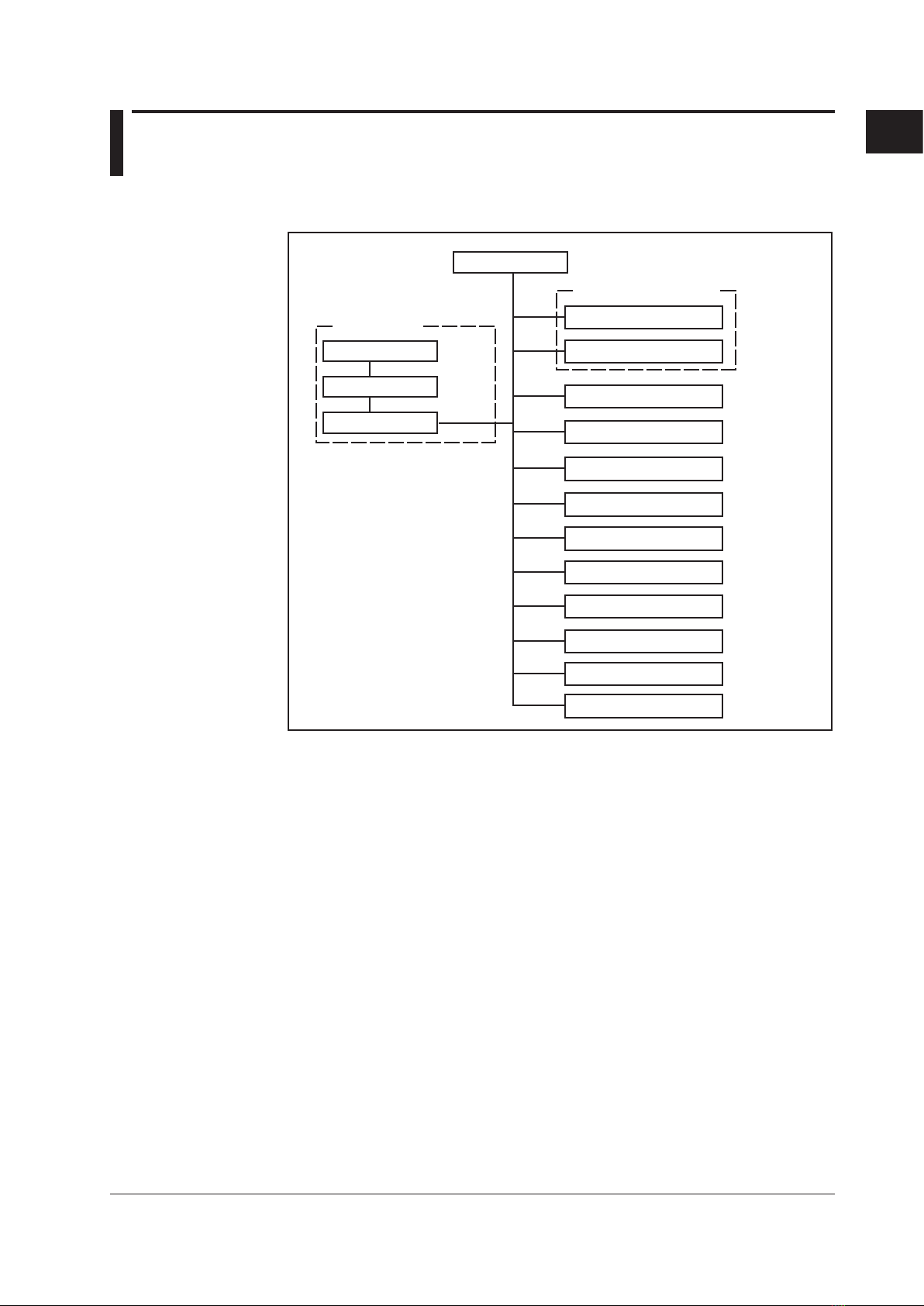

Block Diagram

Data storage functions

Input section

Calculation function

Alarm

Communication function

(optional)

Input terminal

Scanner

A/D

CPU

External storage

Internal memory

Display

Remote control

Relay contact (optional)

(optional)

Pulse input

Transmitter power supply (optional)

USB port

Key

Input Terminal Section

For connecting the measurement input signal wires. The terminals can be used for DC

voltage, thermocouple, resistance temperature measurement, and contact input.

•The reference junction compensation circuit for thermocouples is built in.

• Proven transistor method for measuring the temperature of the terminals.

• Metal core construction used in the internal printed circuit boards to equalize

temperature.

•Input terminals removable.

Scanner Section

Switches the measured input signal (channel). The input signal switching section uses

highly reliable solid state relays (SSR).

A/D Conversion Section

Converts analog signals to digital signals. It is a PWM (pulse width modulation) type

converter. A/D converter calibration data is stored in an EEPROM.

For the correspondence between input channels and A/D converters, see “Measurement

Accuracy” on page 3-6.

1-2 SM MV1000-01E

Saving Data

The capacity of the internal memory is either 80 MB (standard memory) or 200 MB

(expansion memory).

The CF card can be used as an external memory medium.

Display/Keys

The MV uses an LCD display. You can control the MV with key operations.

Calculation

You can calculate the difference between two measurement inputs, perform linear

scaling, square roots, calibration correction, and other computations.

Alarms

Alarm functions include upper limit alarm and lower limit alarm.

Other Functions

Serial/Ethernet Communication

The MV can communicate with other instruments via the Ethernet, RS-232, or

RS-422/485 interface (with the serial communication option).

Remote Control/Pulse Input

Record start and other operations can be controlled using external signals (with the

optional remote control function).

Counts the number of pulses for each measruement (with the pulse input option).

Relay Output

The MV can output alarms or FAIL/Status (optional).

Transmitter Power Supply Output

The MV can output 24 VDC for use as a power supply for transmitters (optional).

USB Port

Allows connection with USB keyboard and USB flash memory devices.

1.1 Principles of Operation

2-1

Troubleshooting

SM MV1000-01E

1

2

3

4

5

6

7

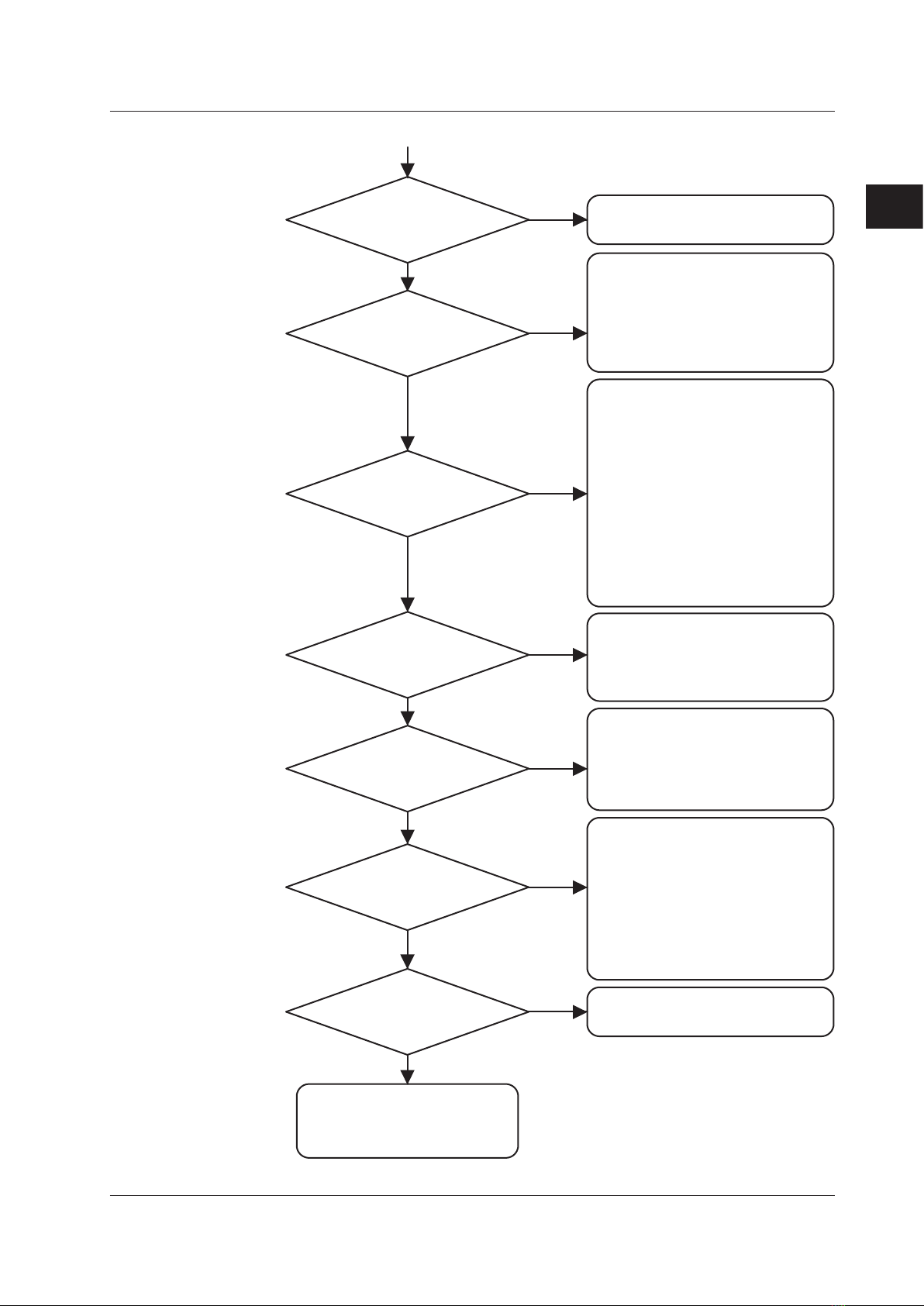

2.1 Failure Analysis Flow Chart

When a failure occurs, refer to the flow chart below for corrective actions.

See No. 5 of the checklist

in section 2.2.

See No. 1 of the checklist in

section 2.2.

Has the backlight gone out due

to the LCD’s backlight saver?

Other than the display,

is the instrument functioning

normally?

Is an appropriate power

supply being input?

Is the power supply wired

correctly?

Is the power switch* ON?

Does the switch operate

normally?

Doesn’t function at all

(nothing is displayed)

Turn the switch ON correctly.

Wire it correctly.

Supply power of voltage and

frequency that conforms to

the specifications.

Restore the original brightness

through key operation.

Try replacing the backlight.

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

NO

YES

Has the instrument

been operated longer than the

recommended replacement period

for the backlight (5 years)?

Chapter 2 Troubleshooting

2-2 SM MV1000-01E

Is the key lock set?

Have measures against

external noise been taken?

See No. 4 of the checklist.

See No. 2, 3, 7, 9, and 10 of the

checklist in section 2.2.

Release the key lock setting.

Keys do not operate correctly

If there is a problem with a display

screen or other function

NO

YES

YES

NO

• Keep measurement input,

communication, and other

wires and cables away from

noise sources.

• Be sure to ground all

instruments.

• Use shielded cables for

wiring measurement input,

communication, and other

circuits.

• Use isolation transformers

on power supply lines.

• Insert filters on power supply

lines.

• If inductive loads are used

on alarm lines, insert surge

absorbers in the lines.

Note

If menu items required for screen menus or function menus are not displayed, check menu

customization settings.

Is the memory medium

(CF card) working normally?

Is it a recommended

device?

See No. 8 of the checklist

in section 2.2.

Replace the memory medium

(CF card) with a new one.

Malfunction of external medium

(CF card)

YES

NO

2.1 Failure Analysis Flow Chart

2-3

Troubleshooting

SM MV1000-01E

1

2

3

4

5

6

7

2.1 Failure Analysis Flow Chart

Is the input wiring correct?

Is a constant ambient

temperature maintained?

Have appropriate measures

against noise been taken?

Are the range, span, and other

input settings appropriate?

Does the input meet the

input specifications?

Problems related to measurement

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

Ensure that the input

specifications are met.

Set them correctly.

• Enter range, span, and other

input settings that are

appropriate.

• When using the calibration

correction function, check the

settings for the calibration

correction.

• Keep input wires and cables

away from noise sources.

• Be sure to ground the recorder.

• Ground the measured object

properly.

• For thermocouple measurement,

insulate points of contact

between the measured object and

thermocouple.

• Use shielded cables for input

wiring.

• Change the integral time setting

of the A/D converter.

• Use moving average on the input.

• Attach input terminal covers.

• To avoid temperature changes in

the vicinity of input terminals,

keep fan ventilation holes clear,

and keep hot objects away.

• Ensure correct polarity when

wiring.

• Check that terminal wires are

securely connected.

• Do not ground RTDs.

• Replace broken thermocouples.

• Do not connect other instruments

with thermocouples in parallel.

If you must connect it in parallel,

consider using a double element

thermocouple, refraining from

using burnout detection, or

implementing other measures.

• Use one earth connection when

connecting the MV to another

instrument.

Are the RJC

settings and TC, RTD type

settings correct?

See No. 6 of the checklist

in section 2.2.

YES

NO

Are other instruments

connected in parallel?

NO

YES

2-4 SM MV1000-01E

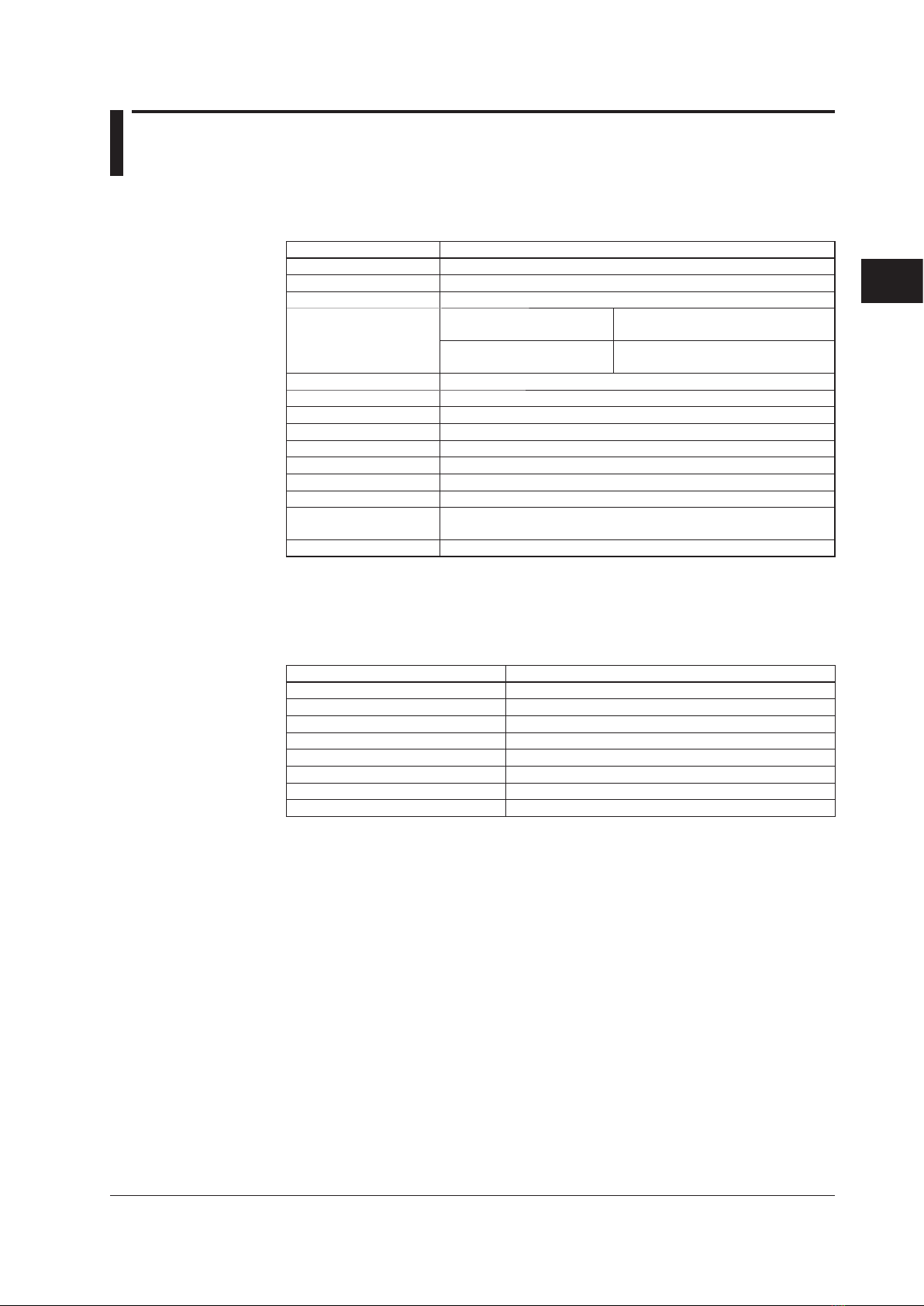

2.2 Troubleshooting Checklist

The table below describes the most common types of failures and their corrective

actions.

No. Phenomenon

Action

Description

Refer to Chapter 6

Check

Adjust

Replace

*1 Part Name MV1000 MV2000

Page Item Page Item

1

The instrument

doesn’t start

even though

the power is

ON

Power supply cable connection/wiring - - - - -

MAIN POWER BOARD ASSEMBLY

12V POWER BOARD ASSEMBLY Power Assembly 6-3 2 6-12 2

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

SUB BOARD ASSEMBLY Sub PCB Assembly 6-3 5 6-12 13

2 FAIL state

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

SUB BOARD ASSEMBLY Sub PCB Assembly 6-3 5 6-12 13

OPTION TERMINAL ASSEMBLY Option Terminal Assembly 6-5 12 6-14 12, 13

3

Abnormal

functioning of

memory

(backup)

Battery connection Battery Assembly 6-3 6 6-12 12

Battery voltage

(must be +3.0 V or more) - - - - -

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

SUB BOARD ASSEMBLY Sub PCB Assembly 6-3 5 6-12 13

4Key operation

abnormality

Check the FFCs*3 for key wiring

(whether pulled out or damaged) - - - - -

SW BOARD ASSEMBLY Bezel Assembly 6-2 1 6-10 1

CONNECTION BOARD ASSEMBLY Bezel Assembly 6-2 1 6-10 1

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

5LCD display

not normal

Check the FFCs*3 for key wiring

(whether pulled out or damaged) - - - - -

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

SUB BOARD ASSEMBLY Sub PCB Assembly 6-3 5 6-12 13

CONNECTION BOARD ASSEMBLY Bezel Assembly 6-2 1 6-10 1

Back Light Unit of LCD ASSEMBLY Bezel Assembly 6-2 1 6-10 1

LCD ASSEMBLY Bezel Assembly 6-2 1 6-10 1

6

Large

measurement

error

Temperature

measurement

abnormal

Keep input wires away from noise

sources (through distance and

shielding, etc.)

- - - - -

Check that the input terminals are not

disconnected from the instrument - - - - -

Check that the input terminal cover is

not loose - - - - -

Check that the RJC (INT/EXT) setting

is correct - - - - -

AD SCANNER BOARD ASSEMBLY AD-STD/ISO 6-3 7, 8 6-12 24, 25

26, 27

7

Fluctuation

in measured

values

Does the integral time setting of the

A/D converter match the power supply

frequency?

- - - - -

Keep input wires away from noise

sources (through distance and

shielding, etc.)

- - - - -

2-5

Troubleshooting

SM MV1000-01E

1

2

3

4

5

6

7

No. Phenomenon

Action

Description

Refer to Chapter 6

Check

Adjust

Replace

*1 Part Name MV1000 MV2000

Page Item Page Item

8

External media

functioning

abnormally

Is the memory medium (CF card)

working normally? - - - - -

Check the FFC*3 for the MEDIA PBA*2

(whether pulled out or damaged) - - - - -

MEDIA BOARD ASSEMBLY - 6-2 - 6-10 -

SUB BOARD ASSEMBLY Sub PCB Assembly 6-3 5 6-12 13

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

9Abnormal

communication

Check communication settings - - - - -

Check communication wiring/cables

(whether pulled out or damaged) - - - - -

POW TERM & COMM BOARD

ASSEMBLY

I-PWR Terminal

24V-Power Terminal

Power Terminal

6-4 8 6-14 3

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

10 USB operation

abnormal

Are connected USB devices (USB

memory and USB keyboard)

operating normally?

- - - - -

Check the FFC*3 for the MEDIA PBA*2

(whether pulled out or damaged) - - - - -

MEDIA BOARD ASSEMBLY

(front panel) Media CF PBA 6-2 - 6-10 -

POW TERM & COMM BOARD

ASSEMBLY (rear panel)

I-PWR Terminal

24V-Power Terminal

Power Terminal

6-4 8 6-14 3

SUB BOARD ASSEMBLY Sub PCB Assembly 6-3 5 6-12 13

MAIN BOARD ASSEMBLY Main PBA 6-3 4 6-12 11

*1: The table shows only the specific parts that must be replaced. When actually carrying out

replacement, the entire assembly that contains a part may have to be replaced.

*2: Printed Board Assembly

*3: Flexible Flat Cable

2.2 Troubleshooting Checklist

3-1

SM MV1000-01E

Testing

1

2

3

4

5

6

7

Chapter 3 Testing

3.1 Acceptance Test

This section describes the procedure to perform the acceptance test.

1. Read the preface to the user’s manual, “Checking the Contents of the Package”

and verify that you have all of the contents.

2. Make sure to understand the operating procedures as described in the user’s

manual.

3. Check each function using the user’s manual.

4. Read and implement section 3.2, “Self Diagnostic Test.”

5. Read and implement section 3.3, “Performance Test.”

3-2 SM MV1000-01E

3.2 Self Diagnostic Test

The MV is provided with complete self diagnostic functions to enhance reliability in

measurement and serviceability.

When you turn ON the power, the MV will automatically execute the following types

of diagnoses alternately and display the results. After these tests are completed, the

recorder is ready for use.

1. Main program (Flash ROM) test

2. Main RAM write/read test

3. A/D and A/D EEPROM test

4. Memory acquisition test (write test from Flash)

5. Ethernet module test

The table below shows the results of the self diagnostic tests when a problem is

detected.

Display upon Error Likely Cause

Refer to Chapter 6

Part Name MV1000 MV2000

Page Item Page Item

901

902

ROM failure.

RAM failure.

Connection between MAIN BOARD

ASSEMBLY and SUB BOARD

ASSEMBLY

– ––––

Replace the SUB BOARD ASSEMBLY

or MAIN BOARD ASSEMBLY

Sub PCB Assembly 6-3 5 6-12 13

Main PBA 6-4 12 6-12 11

910

921

A/D memory failure for

all input channels.

A/D calibration value

error.

Connection between AD SCANNER

BOARD ASSEMBLY and MAIN BOARD

ASSEMBLY

– ––––

Replace the AD SCANNER BOARD

ASSEMBLY or

MAIN BOARD ASSEMBLY

AD-STD/ISO 6-3 7, 8 6-12

24,

25,

26,

27

Main PBA 6-4 12 6-12 11

930 Memory acquisition

failure.

Connection between MAIN BOARD

ASSEMBLY and SUB BOARD

ASSEMBLY

– ––––

Replace the SUB BOARD ASSEMBLY

or MAIN BOARD ASSEMBLY

Sub PCB Assembly 6-3 5 6-12 13

Main PBA 6-4 12 6-12 11

Replace the internal CF card – 6-2 – 6-10 –

940 The Ethernet module

is down.

Check communication settings – – – – –

Connection between POW TERM &

COMM BOARD ASSEMBLY and MAIN

BOARD ASSEMBLY

– ––––

Check the communication cables and

LINK LED illumination – ––––

Replace the MAIN BOARD ASSEMBLY

or POW TERM & COMM BOARD

ASSEMBLY

Main PBA 6-4 12 6-12 11

I-PWR Terminal

24V-Power Terminal

Power Terminal

6-4 8 6-14 3

3-3

SM MV1000-01E

Testing

1

2

3

4

5

6

7

3.3 Performance Test

Read the warning and cautions below before beginning tests.

Test Environment

Item Conditions

Ambient temperature 23 ±5°C

Relative humidity 20 to 80% RH

Atmospheric pressure 86 kPa-106 kPa

Power supply voltage

AC power supply

(Power supply suffix code:-1) 90 to 132 VAC, 180 to 264 VAC

12 VDC power supply

(Power supply suffix code:-2) 10.0 to 28.8 VDC

Power supply frequency Nominal frequency ±1%

Power supply waveform Distortion factor of 5% or less

DC power supply ripple Content ratio of 0.1% or less

Vibration A value having negligible effects on the instrument

Position Within ±3% of the specified position

Interference*1 A value that does not affect the measured results

Electrical field A value that does not affect the measured results

Magnetic field A value that does not affect the measured results

Atmospheric pollutants Levels of corrosive gasses, vapors, salts, and dust that do not affect

the measured results.

Other external effects*2 A value that does not affect the measured results

*1 Interference refers to common mode noise, series mode noise, power supply noise, and

other phenomena in the signal line.

*2 Other external effects include luminance, draft, ultrasonic waves, and radiation.

Test Instruments

Instrument Specifications

DC voltage generator Accuracy: ±0.005% of setting + 1 µV

DMM Accuracy: ±0.005% of rdg + 1 µV

Variable resistors Accuracy: 0.01% + 2 mΩ or better

Insulation tester 500 VDC

Withstand voltage tester 500 to 2300 VAC, 1000 VDC

Function generator Accuracy: ±20ppm of setting for 100 Hz

0°C standard temperature device Accuracy: ±0.05°C

Thermocouple (Type T) Calibrated

Instrument Operation

For operating procedures in setting mode and basic setting mode, see the following

manuals.

•MV1000 First Step Guide (IM MV1000-02E)

• MV2000 First Step Guide (IM MV2000-02E)

• MV1000/MV2000 User’s Manual (IM MV1000-01E)

Tests

The following tests are explained.

• Insulation Resistance • Reference Junction Compensation Accuracy

• Protective Grounding • Battery Backup

• Withstand Voltage • Pulse Input Function (Option)

• Measurement Accuracy

3-4 SM MV1000-01E

3.4 Test Procedures

Insulation Resistance

● TestProcedures

Perform a measurement with an insulation resistance meter and check whether the

results satisfy the reference values. Perform the measurement with the power switch

turned ON.

Reference Value

Terminals Measured Reference Value Condition

Between the power and protective ground

terminal 100 MΩ or more Short the L (+) and N (–)

terminals.

Between the input and protective ground

terminal 100 MΩ or more Short all input terminals.

Between the Ethernet and protective

ground terminal 100 MΩ or more Short all pins of the Ethernet

terminal.

Between RS-422-A/485 SG and

RS-422-A/485 FG terminals 100 MΩ or more With the /C3 option.

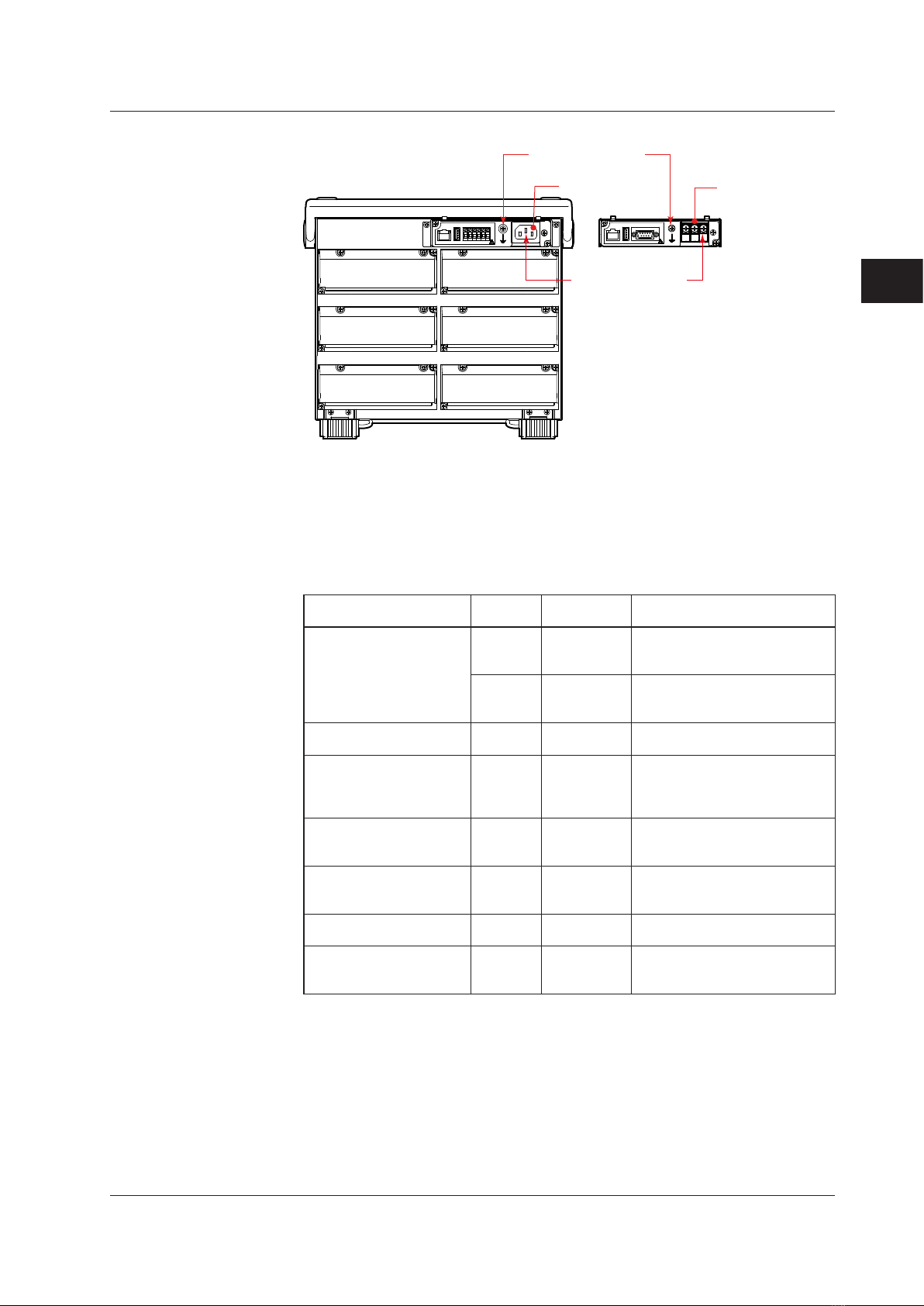

Protective Grounding

● TestProcedures

Perform a resistance measurement with a DMM (digital multimeter), and check

whether the results satisfy the reference values.

Reference Value

Measured Location Reference Value

Between the protective ground terminal

and functional ground terminal 0.2 Ω or less

MV1000

Functional ground

terminal

Power inlet

Protective ground

terminal

Power supply

screw terminals

3-5

SM MV1000-01E

Testing

1

2

3

4

5

6

7

MV2000

Power inlet

Functional ground

terminal

Power supply

screw terminals

Protective ground

terminal

Withstand Voltage

● TestProcedures

Perform the test with a withstanding voltage tester, and check whether the results

satisfy the reference values. Perform the measurement with the power switch turned

ON.

Test time: 1 minute

Tested Terminals Applied

Voltage

Maximum Allowable

Leakage Current

Condition

Between the power and

protective ground terminals

2.3 kVAC 10 mA

For models with 100-240 VAC

power supply.

Short the L and N terminals.

0.5 KVAC 10 mA

For models with 12 VDC power

supply.

Short the + and – terminals.

Between the input and

protective ground terminals 1.5 kVAC 2 mA Short all input terminals.

Between input terminals 1.0 kVAC 1 mA

Short the odd and even channels

of the A/+, B/- terminals*, and

measure between odd and even

channels.

Between relay contact

output and protective

ground terminals

1.6 kVAC 2 mA

With the /A1, /A2, /A3, /A4, or

/F1 option. Short all relay contact

output terminals.

Between the remote control

input and protective ground

terminals

1.0 kVDC 2 mA With the /R1 option. Short all

remote control input terminals.

Between pulse input and

protective ground terminals 1.0 kVDC 2 mA With the /PM1 option. Short all

pulse input terminals.

Between 24 V transmitter

power supply output and

protective ground terminals

500 VAC 10 mA

With the /TPS2 or /TPS4 option.

Short all 24 V transmitter power

supply output terminals.

*The b terminals on the following models are independent on all channels. Short the odd

and even channels of the A/+, B/-, and b terminals, and measure between odd and even

channels.

•MV1004, MV1008, MV2008

• With the /N1 or /N2 option.

3.4 Test Procedures

Other manuals for MVAdvanced MV1000

1

This manual suits for next models

1

Table of contents

Other YOKOGAWA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Biotech

Biotech Sequence Precision Series instruction manual

Energenics

Energenics UV-MAX ECO user guide

Techne

Techne TC-PLUS Operator's manual

BANDELIN

BANDELIN Sonorex Digiplus DL 102 H Instructions for use

VWR

VWR VWR Mega Star 600R Service manual

Thermo Electron

Thermo Electron Thermo Spectra-Tech Collector II user manual