YOKOGAWA PBDH1000 User manual

User’s

Manual Model 701924

PBDH1000 Dierential Probe

IM 701924-01E

6th Edition

User Registration

YOKOGAWA provides registered users with useful information and services. Please

allow us to serve you best by completing the user registration form accessible from

our website.

https://tmi.yokogawa.com/support/

Contact Us

If you want to resolve a technical support issue or need to contact YOKOGAWA,

please fill out the inquiry form on our website.

https://tmi.yokogawa.com/contact/

PIM 103-06E

i

IM 701924-01E

Thank you for purchasing the PBDH1000 Differential Probe (Model 701924).

This user’s manual contains useful information about the functions and

operating procedures of the PBDH1000 Differential Probe and lists the handling

precautions of the instrument. To ensure correct use, please read this manual

thoroughly before beginning operation.

After reading this manual, keep it in a convenient location for quick reference in

the event a question arises during operation.

List of Manuals

The following manuals are provided for the PBDH1000 Differential Probe (Model

701924).

Manual Title Manual No. Notes

Model 701924 PBDH1000

Differential Probe User’s Manual

IM 701924-01E This manual.

Model 701924 PBDH1000

Differential Probe

IM 701924-92 Document for China

Model 701924 PBDH1000

Differential Probe

IM 701924-93Z2 Document for Korea

The “E” and “Z2” in the manual numbers are the language codes.

Contact information of Yokogawa offices worldwide is provided on the following

sheet.

Document No. Description

PIM113-01Z2 List of worldwide contacts

Notes

• The contents of this manual are subject to change without prior notice as

a result of continuing improvements to the instrument’s performance and

functions. The figures given in this manual may differ from those that actually

appear on your screen.

• Every effort has been made in the preparation of this manual to ensure the

accuracy of its contents. However, should you have any questions or find any

errors, please contact your nearest YOKOGAWA dealer.

• Copying or reproducing all or any part of the contents of this manual without

the permission of YOKOGAWA is strictly prohibited.

Revisions

1st Edition: February 2008

2nd Edition: March 2008

3rd Edition: April 2009

4th Edition: November 2015

5th Edition: October 2017

6th Edition: June 2021

6th Edition: June 2021 (YMI)

All Rights Reserved, Copyright © 2008 Yokogawa Electric Corporation

All Rights Reserved, Copyright © 2015 Yokogawa Test & Measurement Corporation

ii IM 701924-01E

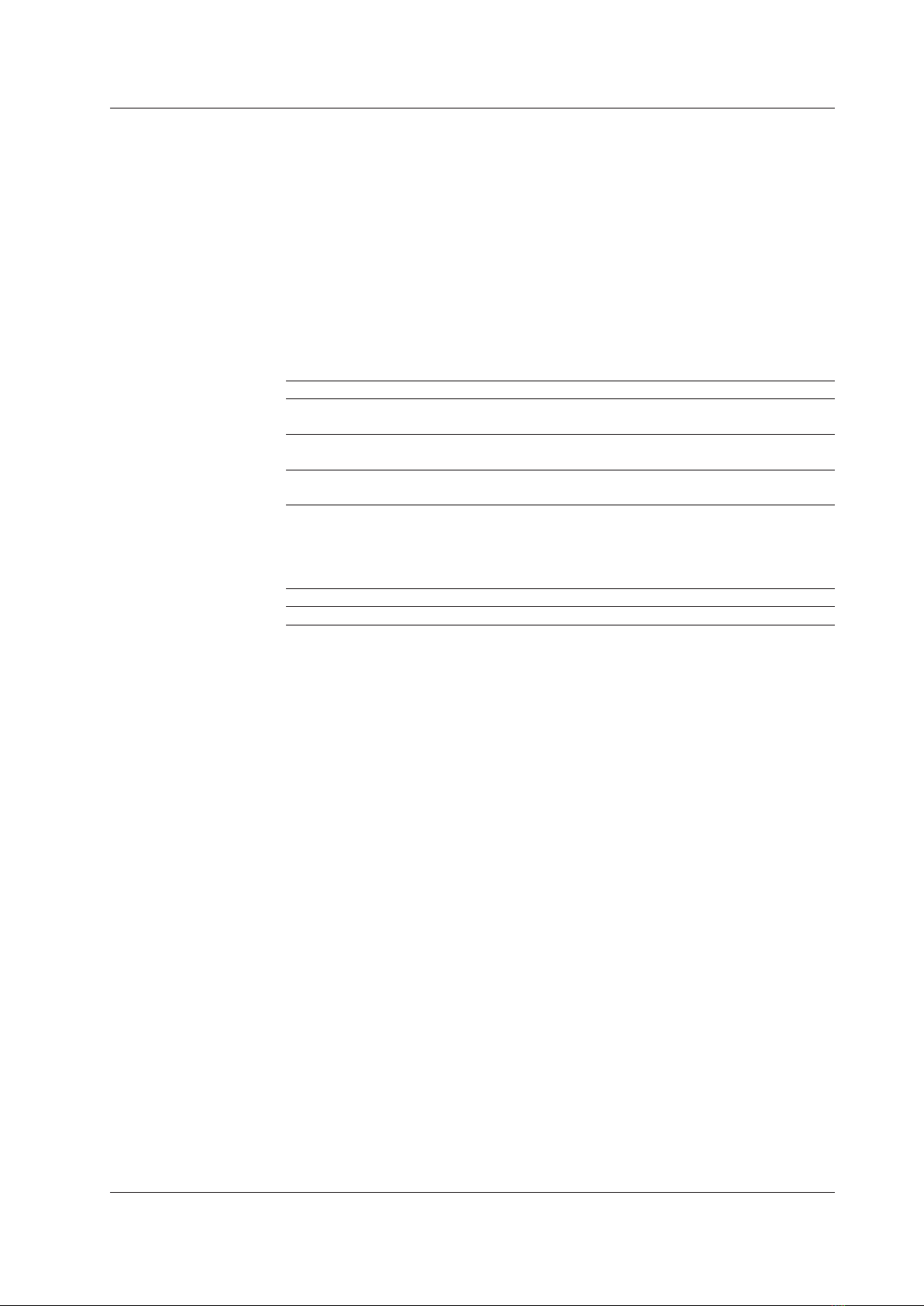

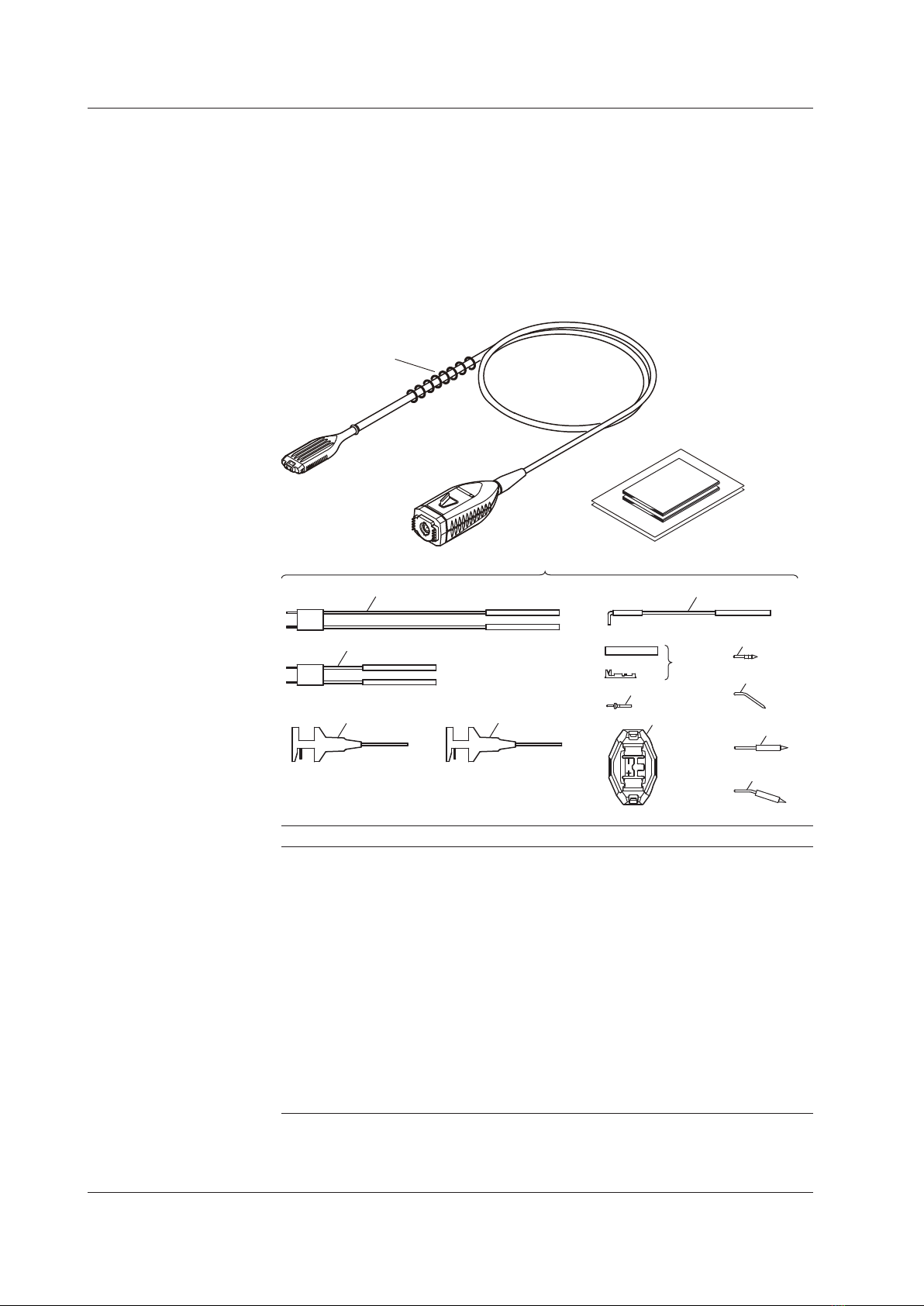

Checking the Contents of the Package

The following accessories are included. If some of the contents are not correct

or missing or if there is physical damage, contact the dealer that you purchased

them from.

• Manuals: 1 set

• Carrying case: 1

• PBDH1000: 1

• Attachments: 1 set

13

12

11

10

9

8

7

6

5

4

3

2

1

Attachments

Name Quantity

1 10-cm pair leads12

2 5-cm pair leads12

3 Red micro clip 1

4 Black micro clip 2

5 6-cm ground extension lead 2

6 Contact, heat-shrink tube1, 2 1 pack (10 pieces)

7 Flanged input pin210

8 Retaining cover22

9 Straight pin 4

10 Angled pin 4

11 Spring-type straight pin 4

12 Spring-type angled pin 4

13 Marker tip38 colors x 1 each

1 Connectable to a 0.64-mm square pin (recommended compatible pin

diameter: 0.65 mm)

2 Extension lead kit

3 Attached to the probe unit.

iii

IM 701924-01E

Checking the Contents of the Package

Optional Accessories (Sold Separately)

Part Name Part Number Quantity

Ground extension lead B8099KQ 5

5-cm pair leads B8099KV 5

10-cm pair leads B8099KU 5

Black micro clip B9852VX 1 pack (10 pieces)

Red micro clip B9852VY 1 pack (8 pieces)

Straight pin B8099DL 10

Angled pin B8099DM 10

Spring-type straight pin B8099DJ 5

Spring-type angled pin B8099DK 5

Flanged input pin B8099KX 5

Retaining cover B8099KY 2

Contact, heat-shrink tube B8099KW 1 pack (10 pieces)

iv IM 701924-01E

Safety Precautions

To ensure safe and correct operation of the instrument, you must take the safety

precautions given on the next page. The instrument may not function if used in

a manner not described in this manual. YOKOGAWA bears no responsibility for,

nor implies any warranty against damages occurring as a result of failure to take

these precautions.

The following safety symbols and words are used in this manual.

Warning: Handle with care. Refer to the user’s manual. This symbol

appears on dangerous locations on the instrument which require special

instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.)

Precautions

For safe use of the instrument, and for best results, please heed the following

warnings and cautions.

WARNING

• Take care to avoid electric shock when connecting the probe to the

circuit under test.

• Never disconnect the probe from the measuring instrument while the

probe is connected to the circuit under test.

• Never use the probe with wet hands, or when the probe itself is wet.

Electric shock can result.

• Before connecting the probe input terminal to the circuit under test,

check that the measuring instrument is properly grounded, and that

the probe output connector is connected to the input connector of the

oscilloscope.

• Ground the measuring instrument.

Always connect the main instrument’s protective grounding.

• Observe the maximum non-destructive input voltage.

Do not apply a voltage that exceeds the following values between the

input and ground.

Instantaneous: ±100 V

Continuous: ±35 V (DC + ACpeak)

• Do not use the probe in humid locations

To avoid electric shock, never use the probe in areas of high humidity.

• Do not use the probe near flammable gases.

To avoid injury and fire, do not use the probe near flammable or

explosive gasses or vapors.

• Avoid exposed circuits.

To prevent injury, when the power is ON, do not touch any exposed

contact points or components.

v

IM 701924-01E

Safety Precautions

CAUTION

• The probe head has undergone a precision assembly process. Take

sufficient care when handling the probe as sudden changes in ambient

temperature and physical shocks can damage it.

• Do not inadvertently twist or pull the cable. The wires inside the cable

can break, causing malfunction.

• Avoid vibration, shock, and static electricity during shipping and

handling. Take extra care not to drop the probe.

• Avoid storing or using the probe in direct sunlight, or in areas with high

temperature, humidity, or condensation. Deformation and deterioration

of insulation can occur resulting in failure to retain product specifications.

• Inspect the probe before use to ensure that damage has not occurred

during shipping and storing. If damage is found, contact your nearest

Yokogawa dealer or sales representative.

• This probe is not water or dust resistant. Do not use the probe in areas

with a lot of dust, or near water.

See below for operating environmental limitations.

CAUTION

This product is a Class A (for industrial environments) product. Operation

of this product in a residential area may cause radio interference in which

case the user will be required to correct the interference.

vi IM 701924-01E

Regulations and Sales in Various Countries and Regions

Waste Electrical and Electronic Equipment

(This directive is valid only in the EU.)

This product complies with the WEEE directive marking requirement.

This marking indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive, this

product is classified as a “Monitoring and control instruments”

product.

When disposing products in the EU, contact your local Yokogawa

office in Europe. Do not dispose in domestic household waste.

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test &

Measurement Corporation for this product in the EEA. To contact Yokogawa

Europe B.V., see the separate list of worldwide contacts, PIM 113-01Z2.

Disposal

When disposing of this product, follow the laws and ordinances of your country

or region.

vii

IM 701924-01E

Conventions Used in This Manual

Improper handling or use can lead to injury to the user or

damage to the instrument. This symbol appears on the

instrument to indicate that the user must refer to the user’s

manual for special instructions. The same symbol appears in

the corresponding place in the user’s manual to identify those

instructions. In the manual, the symbol is used in conjunction

with the word “WARNING” or “CAUTION.”

WARNING Calls attention to actions or conditions that could cause serious

injury or death to the user, and precautions that can be taken

to prevent such occurrences.

CAUTION Calls attentions to actions or conditions that could cause light

injury to the user or damage to the instrument or the user’s

data, and precautions that can be taken to prevent such

occurrences.

Note Calls attention to information that is important for proper

operation of the instrument.

viii IM 701924-01E

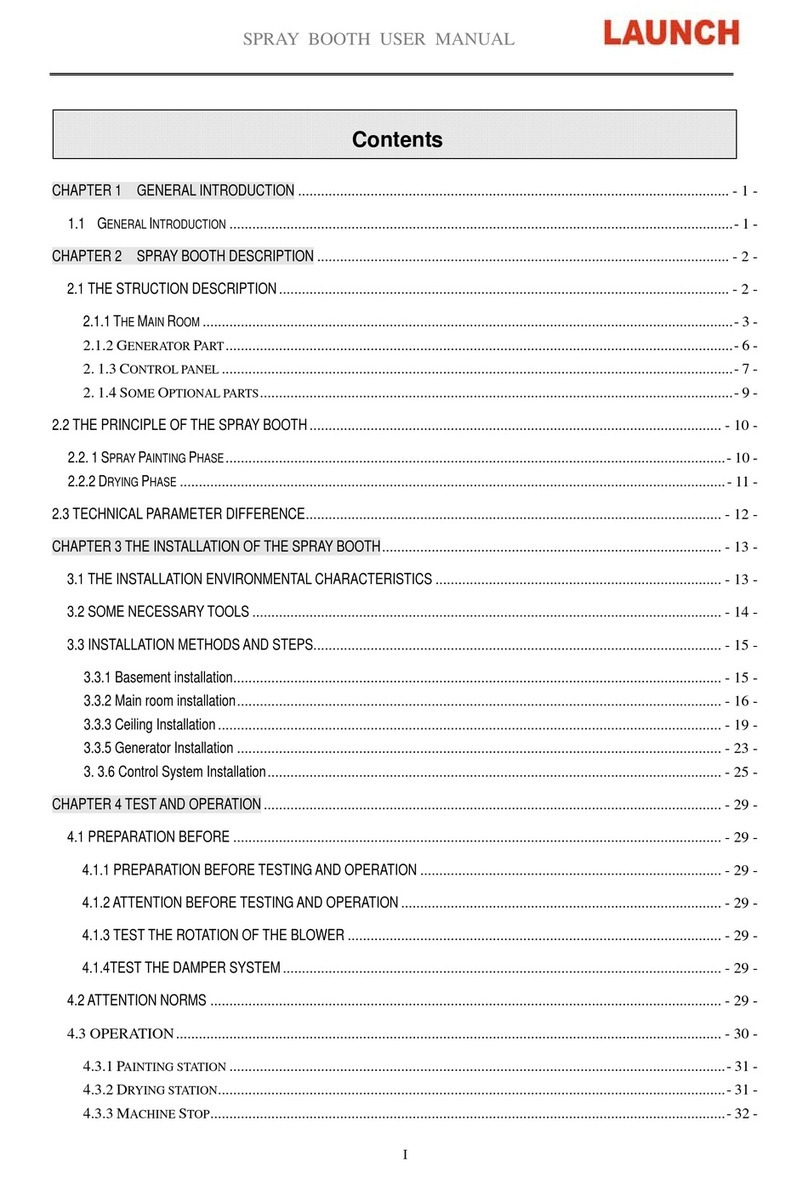

Contents

List of Manuals................................................................................................................... i

Checking the Contents of the Package............................................................................. ii

Safety Precautions........................................................................................................... iv

Regulations and Sales in Various Countries and Regions............................................... vi

Conventions Used in This Manual .................................................................................. vii

Product Overview..............................................................................................................1

Features............................................................................................................................1

Component Names ...........................................................................................................2

Usage Precautions............................................................................................................3

Operating Procedures.......................................................................................................3

Product Specifications .................................................................................................... 11

Appendix 1 Frequency Characteristics of Each Attachment................................... App-1

Appendix 2 Input Equivalent Circuit and DC Voltage Accuracy.............................. App-4

1

IM 701924-01E

Product Overview

The PBDH1000 Differential Probe is a 1-GHz bandwidth, differential-input,

active probe that is used in combination with a digital oscilloscope that has a

YOKOGAWA probe interface (hereafter referred as digital oscilloscope with a

probe interface).

To use the probe, you simply connect it to a BNC input terminal on a digital

oscilloscope with a probe interface.

* For information about digital oscilloscopes with a probe interface, contact your

nearest YOKOGAWA dealer.

Features

• Allows direct observation of differential signals

• Common mode rejection capability

• Wide frequency bandwidth from DC to 1 GHz

• High input impedance (1 MΩ, approx. 1.1 pF between each input terminal

and ground)

• Able to receive power from a digital oscilloscope with a probe interface

• Allows a digital oscilloscope with a probe interface to automatically detect the

probe*

• Comes with various attachments that can be changed according to the item

that you want to measure

• Compact and lightweight

* For a DL9000 Series digital oscilloscope to automatically detect this probe, the

DL9000 firmware version must be 4.05 or later.

2IM 701924-01E

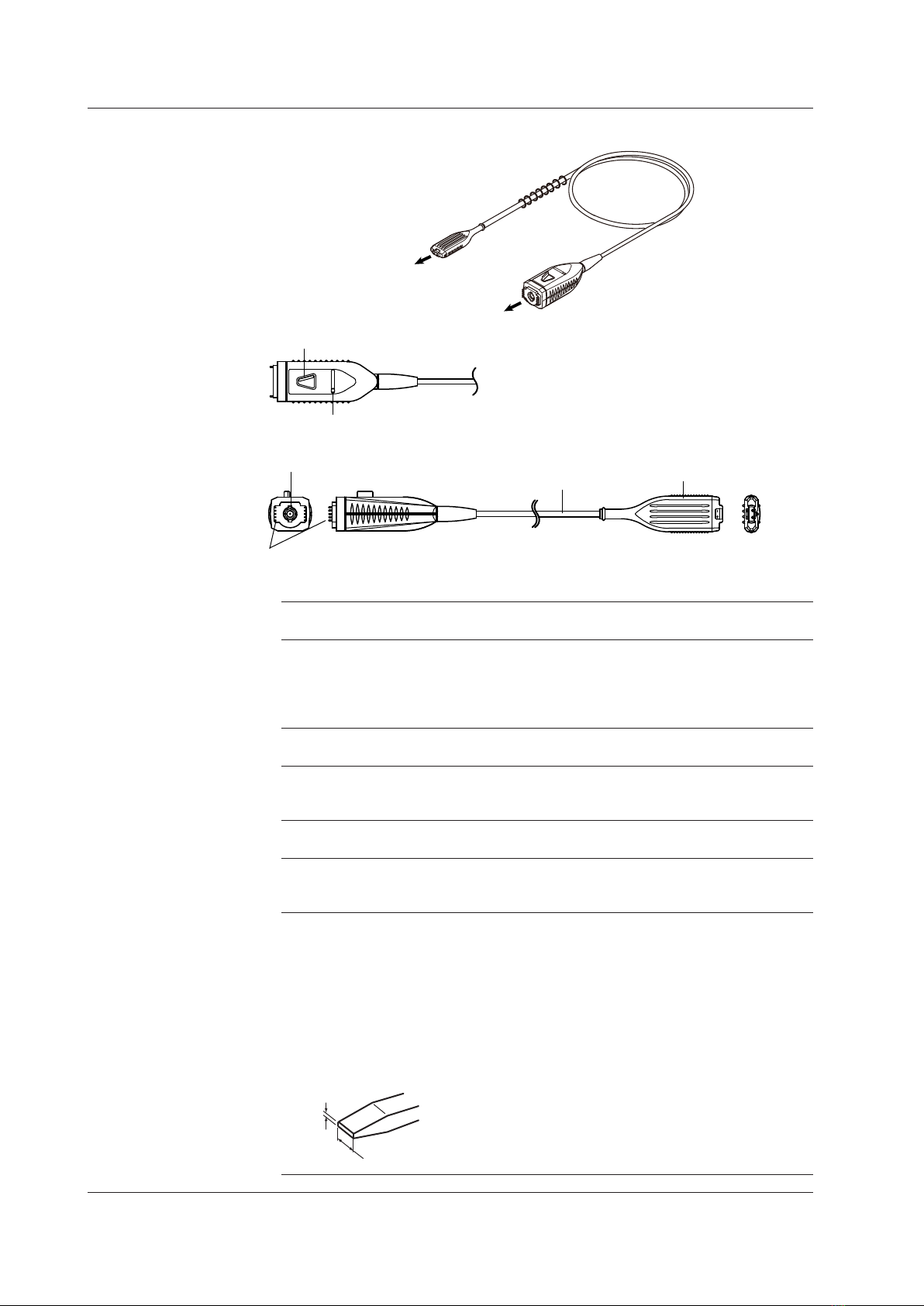

Component Names

Probe head

Cable

Probe interface

Add various

attachments, connect to

circuit under test

To digital oscilloscope input

Latch release lever

Output terminal

Cable Probe head

Interface

spring pin

Variable resistor for adjusting offset voltage

Probe interface

Connects to a digital oscilloscope input.

Interface spring pins

When the probe output terminal is connected, these pins touch the pad on the

oscilloscope interface board. The probe’s power is supplied through these interface

pins. The interface pins are also used to supply a offset voltage and used by the

DL9000 to automatically detect the probe.

Cable

Connects the probe interface and the probe head.

Probe head

Connect various attachments to the signal input terminals, and then connect to the

item you want to measure.

Latch release lever

Releases the lock connecting the probe output terminal to the oscilloscope input.

Output terminal

The output terminal is a BNC connector. It connects to an oscilloscope input BNC

connector.

Variable resistor for adjusting offset voltage

You can adjust the offset voltage using an appropriate driver as described below.

Adjustment driver

Use an adjustment driver that fits into the adjustment groove. Using a driver with

a large grip or a driver with a small head can damage the adjustment turn stop or

groove.

Recommended adjustment driver bit dimensions

Head thickness (W): 0.2 to 0.35 mm; head width (L): 1.3 to 1.5 mm;

head shape: flat or Philips

L

W

3

IM 701924-01E

Usage Precautions

CAUTION

Use a soft cloth to wipe away dirt, and be careful not to damage the probe.

Do not immerse the probe in liquid or use abrasive cleaners on the probe.

Do not use any volatile solvents such as benzine.

Do not bring the probe near transformers, circuits with large currents, wireless

devices, or other objects emitting large electric or magnetic fields. Doing so may

produce inaccurate measurement results.

Operating Procedures

Preparation

1. Have the probe and a digital oscilloscope with a probe interface ready.

2. Insert the probe interface completely into the oscilloscope input, and

confirm that the BNC connector and interface pin are securely fastened.

You will hear the latch click when the connectors lock into place.

3. When you connect the probe to a digital oscilloscope with a probe

interface, the probe’s attenuation ratio and input coupling are set

automatically.*

* For a DL9000 Series digital oscilloscope to automatically detect this probe,

the DL9000 firmware version must be 4.05 or later.

4. Attach any of the provided attachments or attachments that you

constructed to the probe head signal input terminals.

Note

If you are connecting the probe to a DL9000 Series digital oscilloscope with software

version earlier than 4.05, manually configure the following settings after you connect

it.For information on how to update the DL9000 Series software, contact your

nearest YOKOGAWA dealer.

• Set the probe attenuation ratio to 50:1.

• Settheinputcouplingto50Ω.

4IM 701924-01E

Attachment Handling

Connect attachments that are suitable for the item that you want to measure

to the signal input terminals illustrated below. Select attachments from the

following list (see page 9 for attachment application examples).

• 5-cm pair lead

Can connect directly to a pin header or the item you want to measure. It

includes a damping resistor that takes pin header connection into account.

• 10-cm pair lead

Used in combination with a micro clip. It includes a damping resistor that

takes the micro clip into account. It is suitable for measuring relatively low-

frequency signals.

• Pin

The following four types are available. They are suitable for measuring

relatively high-frequency signals.

• Straight pin

• Angled pin

• Spring-type straight pin

• Spring-type angled pin

• A lead that you created using a kit

Create your own lead when you need a lead that is longer than the ones

included in the accessories, or when you want to prevent the lead from

coming loose from the probe head by using the retaining cover. For

instructions on how to create your own lead, see the next page.

Note

• The provided pair leads include the following damping resistors. These pair leads

can connect to a 0.64-mm square pin.

5-cmpairlead: 100Ω,1/4W,1%

10-cmpairlead: 150Ω,1/4W,1%

• For typical frequency characteristics of attachments, see appendix 1.

5.08 mm

Positive signal

input terminal

Negative signal

input terminal

GND terminal

Because the probe input is high impedance, the inductance from the probe

head to the circuit under test has a large effect on the measured results of high

frequency signal components. When measuring signals that include frequency

components of 100 MHz or higher, we recommend that you use the shortest

attachments possible for both the positive and negative input terminals.

Operating Procedures

5

IM 701924-01E

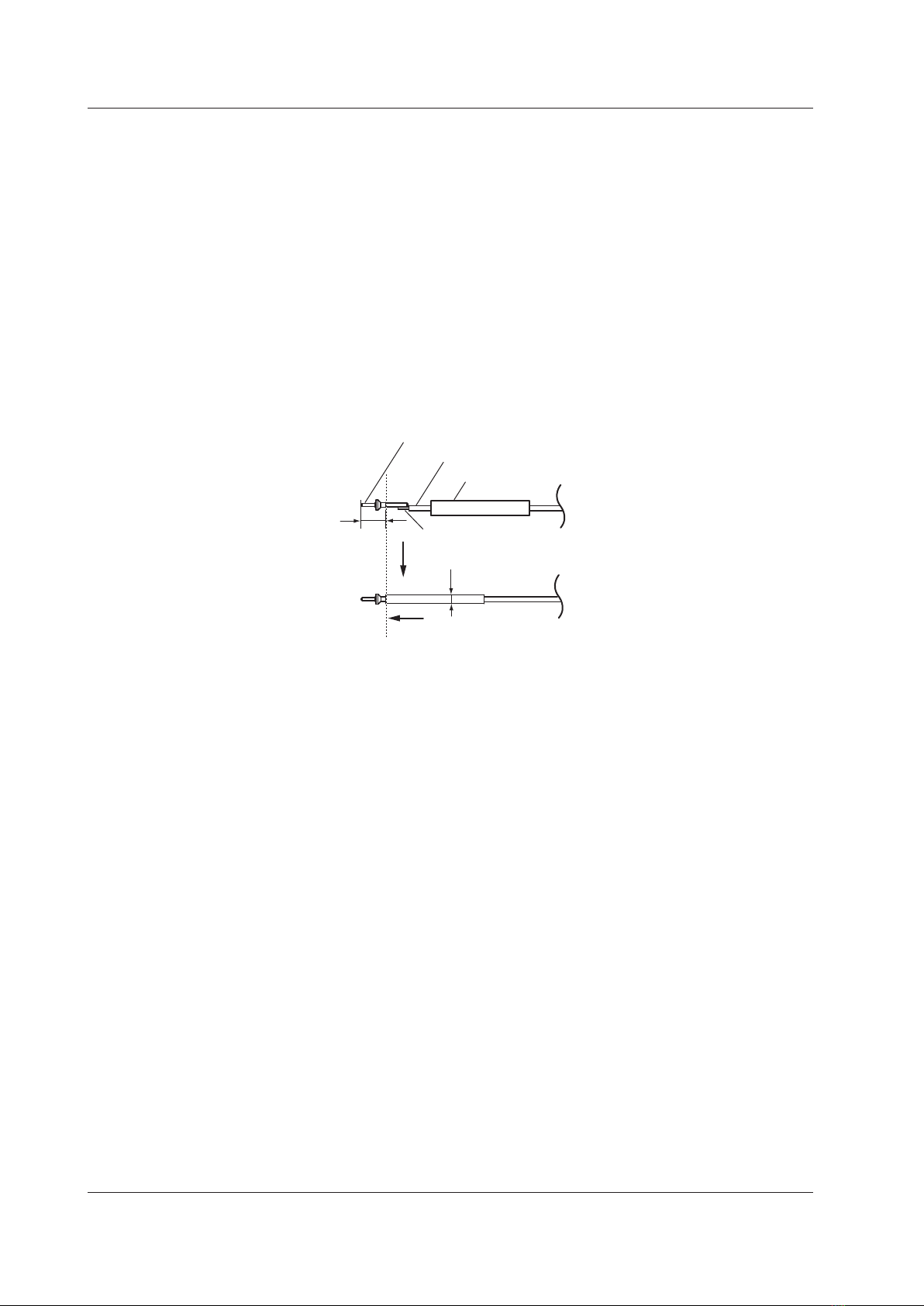

Creating an Extension Lead

You can create your own extension lead using the accessory kit.

At the Circuit-under-Test End

1. Pass the lead wire through a heat-shrink tube for a contact.

2. Crimp or solder the lead wire’s core wire to the contact.

3. Cover the contact with the heat-shrink tube, and then apply heat with a

drier to fix the tube in place.

In step 2, you can insert a damping resistor between the lead wire and contact

as shown in the illustration below on the right.

Contact

<When inserting a resistor>

Resistor

Crimp or solder

Solder

Cover the contact

with a heat-shrink

tube

Solder not allowed*

Crimp or solder

Lead wire (AWG24 to 26 recommended,

maximum diameter: 2.0 mm)

Core wire

Heat-shrink tube for a contact

Lead Wire Length Resistance

Examples of resistances that you can insert

(when using a micro clip)

5 cm 150Ω

10 cm 150Ω

20 cm 180Ω

* If solder gets into this section, the contact or the circuit under test may break.

Note

A dedicated crimping tool is needed to crimp the lead wires (SST-017 by Stack

Electronics Co, Ltd.).

Operating Procedures

6IM 701924-01E

Probe-Head End

4. Pass the lead wire through the heat-shrink tube.

* The heat-shrink tube for the probe-head end is not included. It must be

obtained separately.

5. Solder the lead wire’s core wire to the flanged input pin.

6. Cover the flanged input pin with a heat-shrink tube, and then apply heat

with a drier to fix the tube in place.

Do not cover the section of the flanged input pin to the left of the broken

lines shown in the following figure with the heat-shrink tube. Make sure

that the diameter of the tube after shrinking is 2.0 mm or less. If the

maximum diameter exceeds 2.0 mm, the lead wire will not be able to

pass through the retaining cover.

4.0 mm

(soldering

not allowed*)

φ2.0 mm or less

* If solder gets on this section (4 mm from the tip), the probe may break.

Flanged input pin

Cover with a heat-shrink tube

Solder

Core wire

Lead wire

Heat-shrink tube

Operating Procedures

7

IM 701924-01E

Attaching the Retaining Cover

7. Pass the flanged sections of the two input pins through the center

retaining-cover holes, and place the input pins on the holders on either

side.

Flange

8. Alignthe+and−markingsontheretainingcovertothoseontheprobe

head, and attach the retaining cover to the probe head.

Check that the retaining cover’s left and right latches are securely locked.

Removing the Retaining Cover

9. While pinching the retaining cover at the top and bottom, remove the

cover from the probe head.

Note

• The retaining cover can only be used with a flanged input pin that is included in

the package.

• You cannot use the probe’s ground terminal if you use the retaining cover.

Operating Procedures

8IM 701924-01E

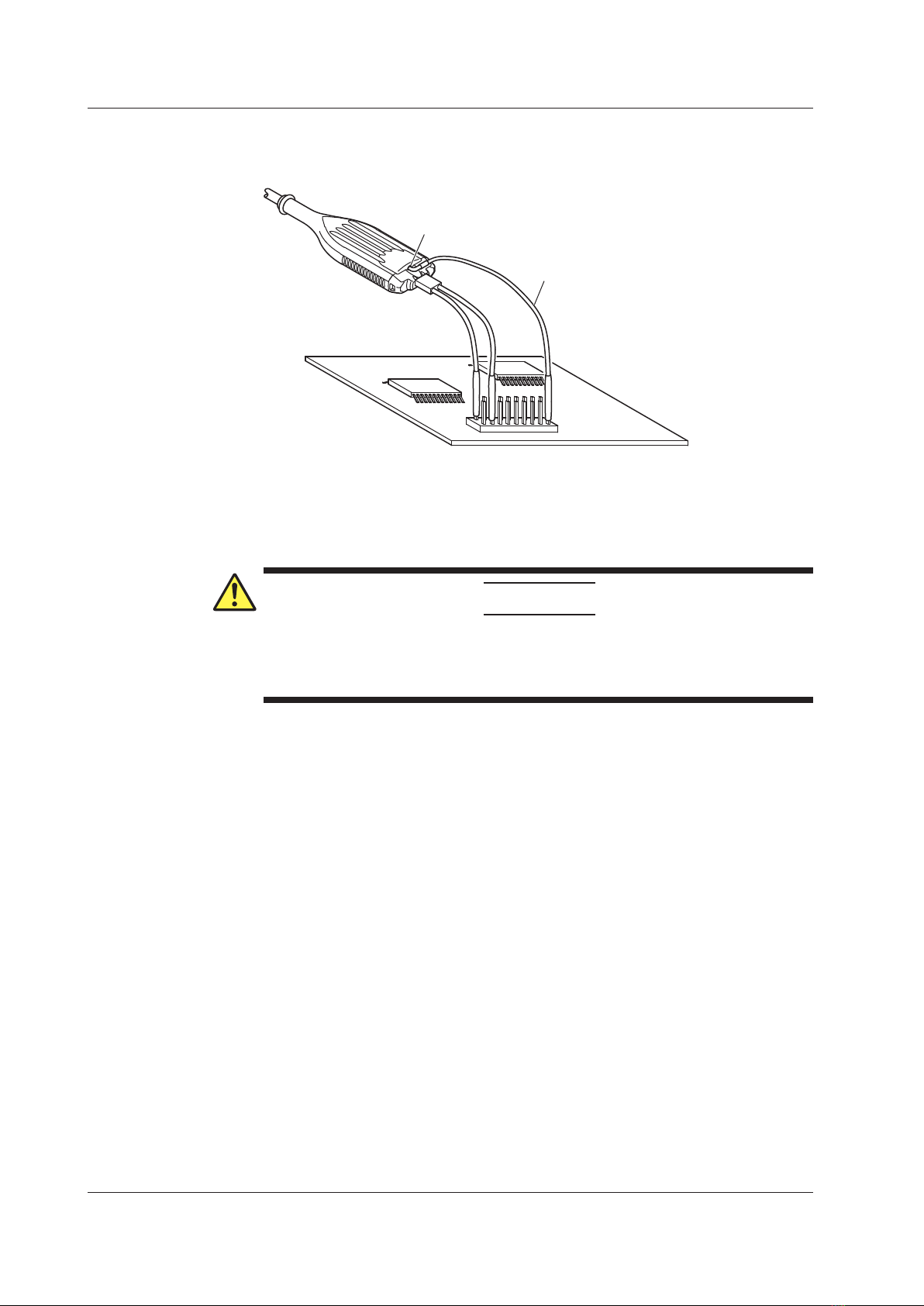

How to Use the Ground Extension Lead

Example

Ground extension lead

Ground terminal

Connecting the probe ground terminal to the common ground on the circuit

under test using the ground extension lead may reduce noise when measuring

low-frequency signals.

CAUTION

Only connect the ground extension lead to the common ground. If you are

measuring a floating circuit, do not use the ground terminal. Doing so may

damage the measuring system or the circuit under test.

Operating Procedures

9

IM 701924-01E

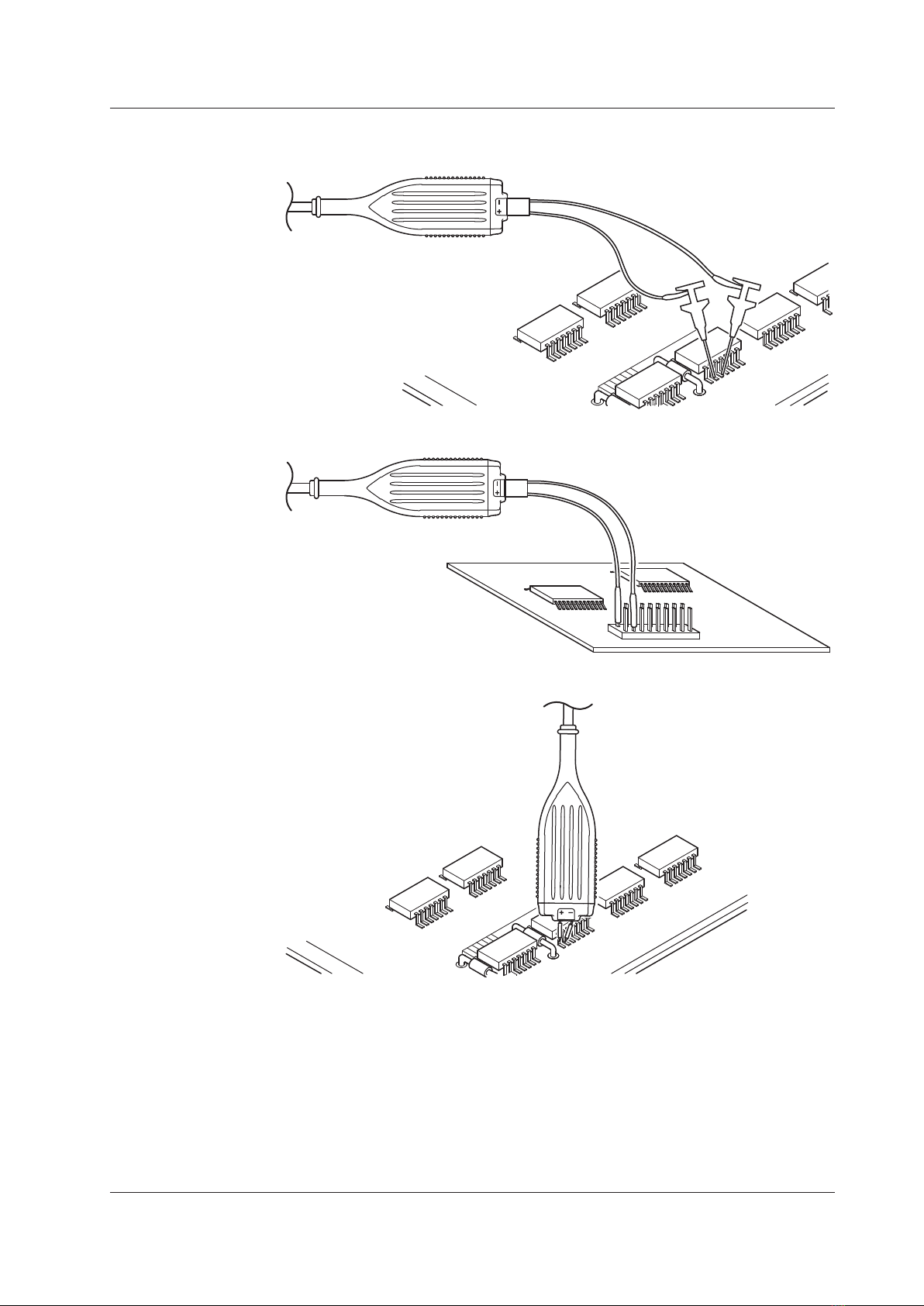

Example

10-cm pair lead with micro chip

5-cm pair lead

Pin (straight, angled, spring-type straight or angled)

Operating Procedures

10 IM 701924-01E

Warm-up and Offset Adjustment

Warm-up

Immediately after connecting the probe, the heat emitted by the probe itself

causes the offset voltage to drift. Warm up the probe for at least 30 minutes

after applying power to stabilize the probe.

Offset Adjustment

You can turn the offset voltage adjustment variable resistor on the probe

interface by using an appropriate adjustment driver (see page 2 for details) to

adjust the residual offset voltage that remains even after warm-up.

CAUTION

Do not turn the variable resistor with excessive force when adjusting the

offset voltage. Doing so may break the variable resistor.

Note

• The offset voltage drifts depending on the ambient temperature. Pay attention to

changes in the ambient temperature when making continuous measurements.

• Only use the offset voltage adjustment variable resistor to adjust the residual

offset voltage. If you deliberately change the offset voltage for some other

purpose, the probe may no longer meet the specifications.

Operating Procedures

Other manuals for PBDH1000

1

This manual suits for next models

1

Table of contents

Other YOKOGAWA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Cannon

Cannon CCS-2100 instruction & operation manual

Rainin

Rainin E-Man Hybrid Getting started

Thermo Scientific

Thermo Scientific TSQ 8000 Evo Preinstallation manual

MELAG

MELAG Carebox Blue user manual

Steinberg Systems

Steinberg Systems SBS-LBM-150 user manual

BioNano Genomics

BioNano Genomics Saphyr System Setup guide