428546-YIM-C-1110

YCCS System Manager and Zone Coordinator Installation Instructions10

Troubleshooting

Use the following information to troubleshoot the

System Manger and Zone Coordinator.

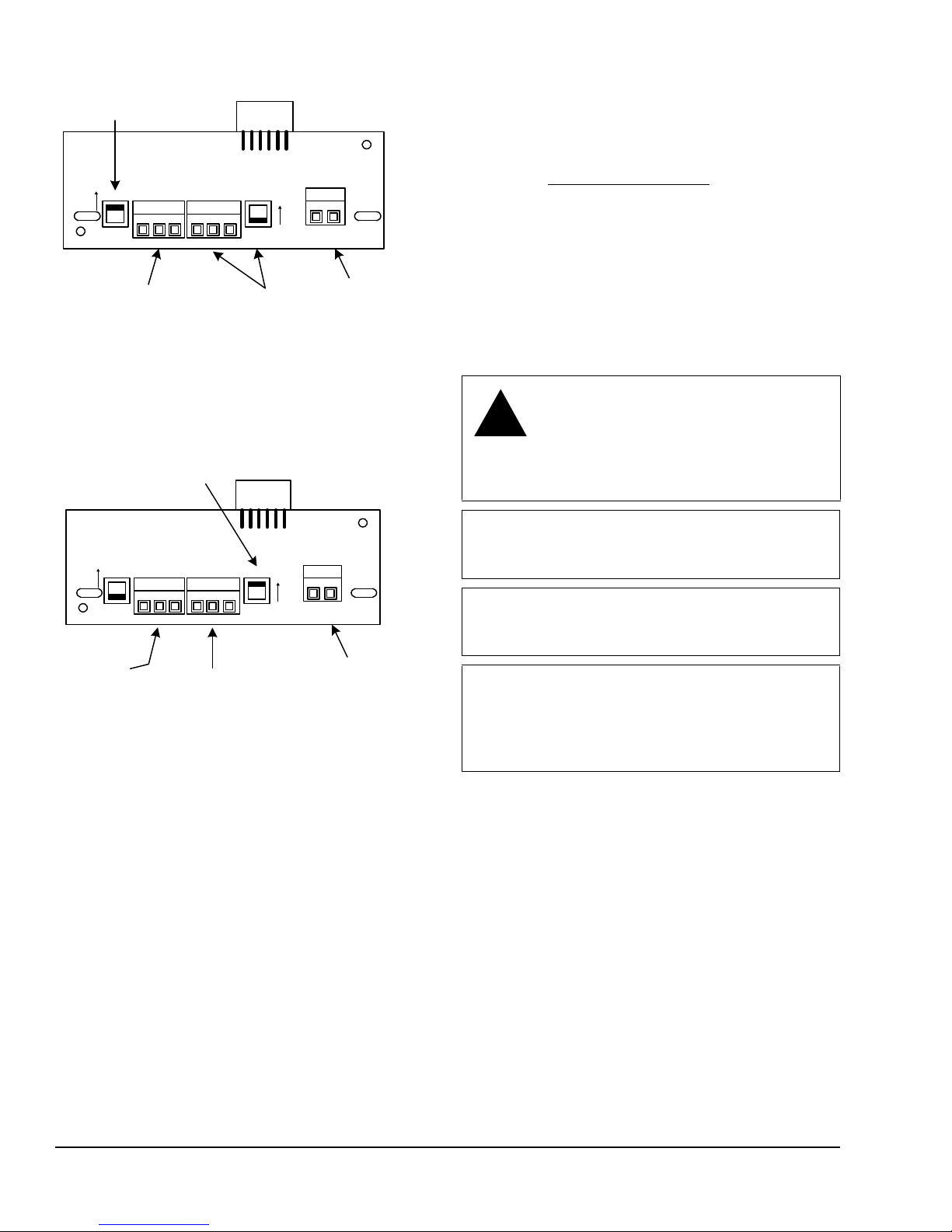

Status LEDs

The System Manager and Zone Coordinator include

LEDs that indicate communication and alarm status for

the controller. Table 6 lists LED descriptions.

Communication Problems

Several factors may influence the behavior of the

System Communication Bus. In addition, certain

problems can affect the Bus in multiple ways and have

multiple symptoms, which makes the exact diagnosis

difficult. For example, duplicate addresses on the Bus

can degrade performance, make the device go offline,

or stop communication completely.

Incomplete Address

The YK-ZCUxx0-0 Zone Coordinator must have the

address switch set between 8–17 on the System

Communication Bus; other settings prevent the Zone

Coordinator from communicating on the System

Communication Bus.

Duplicate Addresses

Two or more devices on a communication Bus cannot

have the same address. For example, two Zone

Coordinators on the System Communication Bus

cannot both have an address of 8. If two devices on the

same Bus have the same address, performance can

degrade or serious communication problems may

occur. These problems include the devices not coming

online and all communication stopping completely.

Check for duplicate addresses, in the following ways,

depending on the severity of the situation:

• If the Bus performance is degraded, check the

address switch settings at the devices with

unreliable communications.

• If the Bus communication problems are severe,

and no communication is present, or you can not

determine where communication is unreliable,

partition (disconnect and isolate a portion of the

Bus for testing purposes) and test the Bus portion

connected to the System Manager and Zone

Coordinator controllers.

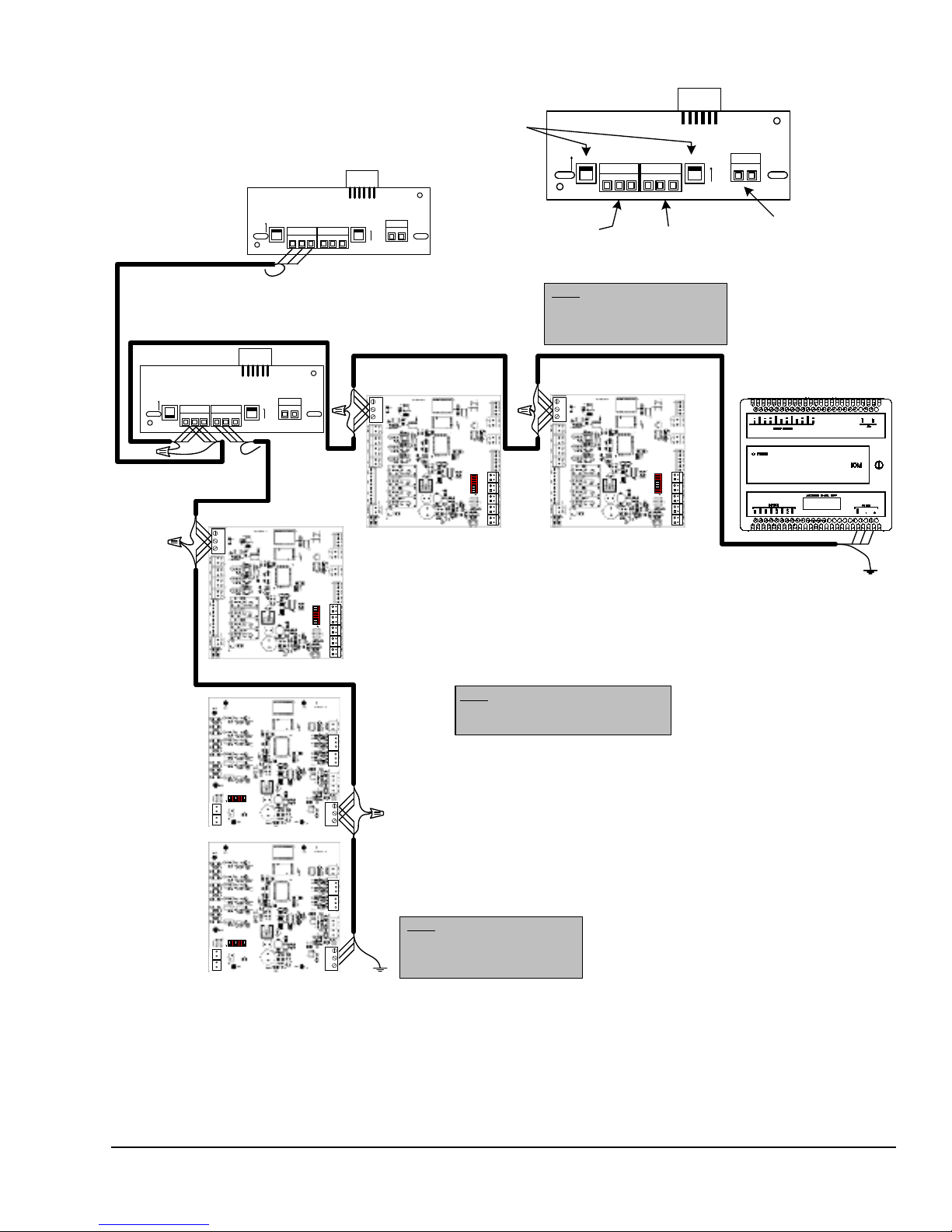

Correcting Physical Communication Bus Problems

The communication bus is subject to a number of

physical factors that can affect performance. Consider

the following list of common physical problems that

affect the communications bus:

• Check status LED to verify power at the controller

•Checkwires

- Verify wire is 22 AWG (0.6 mm) 3-conductor,

twisted, shielded cable.

- Verify shield is continuous and hard-grounded

at one end.

• Check wiring

- Check for and eliminate T-Taps (wire

configurations that create a T shape) and star

configurations.

- Ensure bus is wired in daisy-chain fashion.

- Verify that appropriate devices have three

wires entering and exiting each terminal

(devices at the ends of the trunk do not have

this wiring).

• Check EOL switch settings

- Verify the zone bus EOL switch on the Zone

Coordinator is set to ON and the Zone

Coordinator is located at the end of the zone

bus trunk.

- Verify that only the EOL switch at the end of

the system bus is set to ON and all other

system bus EOL switches are set to OFF.

• Check connections, polarity, and lengths

- Verify communications loops are less than

approximately 304 m (1,000 ft) total in length.

- If you are using one transformer to power

multiple devices, verify the device 24 VAC

power connection follows the polarity of the

common and 24 V terminations.

• Check for opens and shorts

• Check terminations

• Check for sources of interference

Table 6: Status LEDs

LED Description

Green The controller is getting power from the 24

VAC power supply and unacknowledged

alarms are not present.

Red The controller is getting power from the 24

VAC power supply and unacknowledged

alarm conditions are present.

Off Controller is not receiving 24 VAC power

or the controller is in startup mode.