Tappets Adjustment

1. Tappet clearance is pre-set at the factory.

2. Clearance adjustment may need after one hour of running time due

to initial wear. After adjustment, tappet clearance should be checked

during normal maintenance after every 10 hours of running to main

tain maximum performance.

3. Clearance adjustment should be done when the engine is cool.

4. The proper clearance setting is between 0mm (0.000”) and 0.1mm

(0.004”). The adjustment is achieved by loosening the locknut

(“Fig.2”) and turning the adjustment screw. The engine must be at

top dead center on the compression stroke before any adjustments

are made. This engine runs best with the valves set at a tight

setting. If the valves are set too loose, power will be affected.

Cam Gear Timing

If for some reason you have to disassemble your engine, please follow

these important steps on reassembling the cam gear.

1. Remove the carburetor and back plate assembly. Notice the impres-

sion mark or dot opposite the rod journal on the crankshaft.

2. This mark is to point straight down or lined up with the outer case

seam line at the bottom and hold crankshaft securely.

3. Reinstall the cam with the dot facing you. After you fully installing

cam and then check dot should be pointing straight down will give

you right timing.

Operation of YS Super Mount (Option)

1. It is hold by 4 screws, 2 on the front ring and 2 on the rear soft

mount. There are two different height of spacer we provide.

A set spacer (MN110S) : 10mm thickness

B set spacer (MN111S) : 4mm thickness

2. Please be sure not to hit any part of the fuselage by the engine after

it is installed.

3. Ifdamperoilisleaked,rellTAMIYAdampersiliconoil#600.

Damperisaconsumptionparts,pleaseexchangeifyoundworn

or some defect.

Cleaning

This engine uses silicon rubber in many parts. Please use methanol or

model engine fuel for cleaning. Do not use Kerosene, Gasoline, Machine

oil, Automobile parts cleaner or house hold lubricants to clean. It will

harm silicon parts.

Engine Cooling

Be sure to secure cooling air for engine cooling. If it is not enough for the

engine, it causes the regulator and carburetor heat up and makes vapor-

ized or percolates the fuel. It gets deteriorations of engine performance

or stop the engine. Please read carefully below for provision.

1. Please open air intakes and outlets as wide as possible.

2. Take off cowling when you make engine adjustment for a long time.

When air temperature is high, it may heat up the regulator and car-

buretor to make vaporized or percolate the fuel even without cowl-

ing. If it happens, wait till engine well cooling down before you

restart and adjust.

Rusting provision

Donotleavefuelintheengineafterthenalightoftheday.Whenyou

store the engine long period of time, a few drops (about 1cc) of lubricant

oil must be put into the engine from carburetor and clank several times.

Do not use Automobile engine oil.

57

136.5

14

119.4

68.6

149.5

63 25

58

114

Air

Tube B

Fuel Clunk Tank

Regulator

Front Nut

Rear Nut

Front Ring Rear Mount

Battery(4.8~8.4V) Switch

Red

Black

Ignition Box

Brown Red Yellow

Black

Red Black

Plug Cap Screw

* Please tap lightly with a small hammer,

as the spark plug cap is tight fit to the

spark plug.

Tube A

Safety Instructions

In order to use the engine, please read through this instruction manual

carefully. This is a complex,high-performance engine. If you have any

difcultiestounderstandanypartofthisinstructionmanual,pleasecon-

tact the hobby shop from whom you purchased the engine, or contact us

directly.

1. The propeller double locknut assembly supplied with the engine

must be used when mounting the propeller.

2. Alwaysuseagoodqualitypropellerandfollowthemanufacturer’s

instructions.

3. Choose a propeller size that will not allow the engine to exceed the

maximumpracticalRPMinight.

4. Always ensure that no people are in front of or beside the propeller

while the engine is running.

5. To start the engine, set the throttle to the idle position and use an

electric starter.

6. Afterstartingtheengine,alwaysmovebehindthepropellertoadjust

the needle settings.

7. The engine becomes extremely hot both during and after engine

runs.Donottouchtheengine,exhaustheader,mufer,oranyparts

attached to the engine while it runs or before it has cooled down.

8. Iftheenginerunsincorrectly,DON’TFLY.

9. Do not use this engine for anything other than radio controlled air

planes. Do not use it for radio controlled helicopters.

10.Youhavefullresponsibilitywhileyouoperatetheengine.Pleasebe

extra careful for your safety and the safety of others whenever you

operate the engine.

Installation

Connect the engine to the tank and CDI system as in “Fig.1”.

The battery and switch for the CDI unit is not supplied with the engine.

Thesoftmountandfuellterareoptional.

1. The recommended fuel tank size is 500cc to 700cc (18 to 24 oz).

A standard clunk type fuel tank may be used. If this type of tank is

used, you must use the special clunk supplied with the engine.

Please note that with this clunk, some fuel cannot be drained from

the tank. As soon as any part of the clunk becomes exposed, the

engine will stop due to air entering the fuel pump.

2. Alwaysuseafuelfilter.WerecommendYSfilter(6720).Withthisfiter,

youmustremovetheclothportionofthelterandleaveboththe

metallterscreensinplace.

3. Becauseoftheengine’spumpsystem,thetankmaybeplacednear

theaircraft’sC.Gpositrion.Thefuellevelinthetankwillnotinuence

the engine.

4. Pleasepayconsiderationtoavoidchangoftheignitionbox’swires

from vibration. Use the plastic “spiral wrap” supplied with the engine

to wrap the shielded plug wire.

5. Please place the ignition box about 15cm away from the receiver.

Some radio components may need to be over 30cm away from

ignition components to avoid interference. Wrap the ignition box in

foam rubber or other vibration absorbing material(in the same man-

ner as the receiver is mounted), and fasten (e.g. using Velcro straps).

Do not use the bracket holes to directly mount the ignition box to the

aircraft.

Fuel

1. Use an alchole based straight fuel ( 0% nitro and 10-20% oil ). Youcan

not use gasoline fuel.

2. Whenllingthetank,disconnectFuelTube“A”orFuelTube“B”

(Fig.1)forlling,useastopperontheFuelTube“A”toavoidooding

the engine.

Propeller

1. Due to the high power ooutput of the DZ185 engine, it is supplied

with a double locknut system for added safety. Mount the propeler

and tighten the rear nut, followed by the front nut. The rear nut

has an offset shoulder that the recess of the front nut will secure itself

against.

2. Please check and retighten propeller locknut periodically.

3. Select a propeller that will allow the engine to run at a maximum of

between6,000to8,000RPM.

4. We recommend sizes 19x11, 20x10.5, 20.5x10. Other propeller

sizes may be used as long as the correct RPM range is maintained.

High Speed Needle Valve Adjustment

1. An electric starter is mandatory for this engine.

2. Turning the needle valve clockwise leans the mixture. Turning it

couner-clockwise richens the mixture. A good starting position for the

high speed needle valve is 1 and 1/2 turns open from the fully closed

postion.

3. To prime the engie, check that the ignition is switched OFF before

turning the engine over with an electric starter (throttle fully open)

4. Close the carburetor to the idle position, turn ignition ON and start

the engine with an electric starter. Run the engine at a high idle RPM

to warm it up.

5. Brake-in the engine with one or two tanks of fuel on the ground, with

good rich mixture setting adjusting for the best high speed needle

position.

6. Toachievebesthighspeedneedlevalveposition,runtheengine

with the throttle fully opened. Gradually turn the needle valve

clockwise untill the RPM beginns to drop. The position of the needle

valve corresponding to the maximum engine RPM is referred to as

the peak position. Turn the needle valve counter-clockwose

approximately 1/8 turns from the peak position.

Breake-in

1. Start the engine with high speed needle valve open 1 and 1/2 turns

from the fully closed position and with the throttle at the idle position

2. After starting the engine, increases the RPM gradually by operating

the throttle. Do not suddenly apply full throttle.

3. Ifthemixtureistoorichandtheenginemisres,turntheneedle

valve clockwise to make the mixture leaner.

4. Breake-intheenginewithoneortwotanks(600ccor20oz.tank)of

fuel on the ground, running at the richest possible mixture setting.

Battery for CDI Unit

Use4.8~8.4VNi-Cd,Ni-MHorLi-Pobatterywithacapacityofaround

700mAh.Thiswillbesufcientfor5-10minutesights.

Idling adjustment

1. Ideal idling range is between 1,200 and 2,000RPM.

2. When the regulator is turned counter-clockwise, the idle mixture is

leaner. When the regulator is turned clockwise, the idle mixture is

richer. Adjust regulator in 45 degree increments.

3. Ifidlemixtureistoorich,theengine’sRPMwillgraduallydropand

the engine will eventually stop after continuous idling. Also if

the engine stops when you change the attitude of the airplane on

theground,theidlemixtureistoorich.Iftheengine’sidleRPMis

unstable during continuous idling, the idle mixture is too lean.

Spark Plug

Use spark plug supplied with the engine. The plug gap should be 0.30mm

(0.013”) and 0.45mm (0.018”). If plug gap become over 0.5mm (0.020”)

,theenginewillmisre.Ifthegapexceeds0.45mm,taptheelementwith

a hammer reduce to the gap.

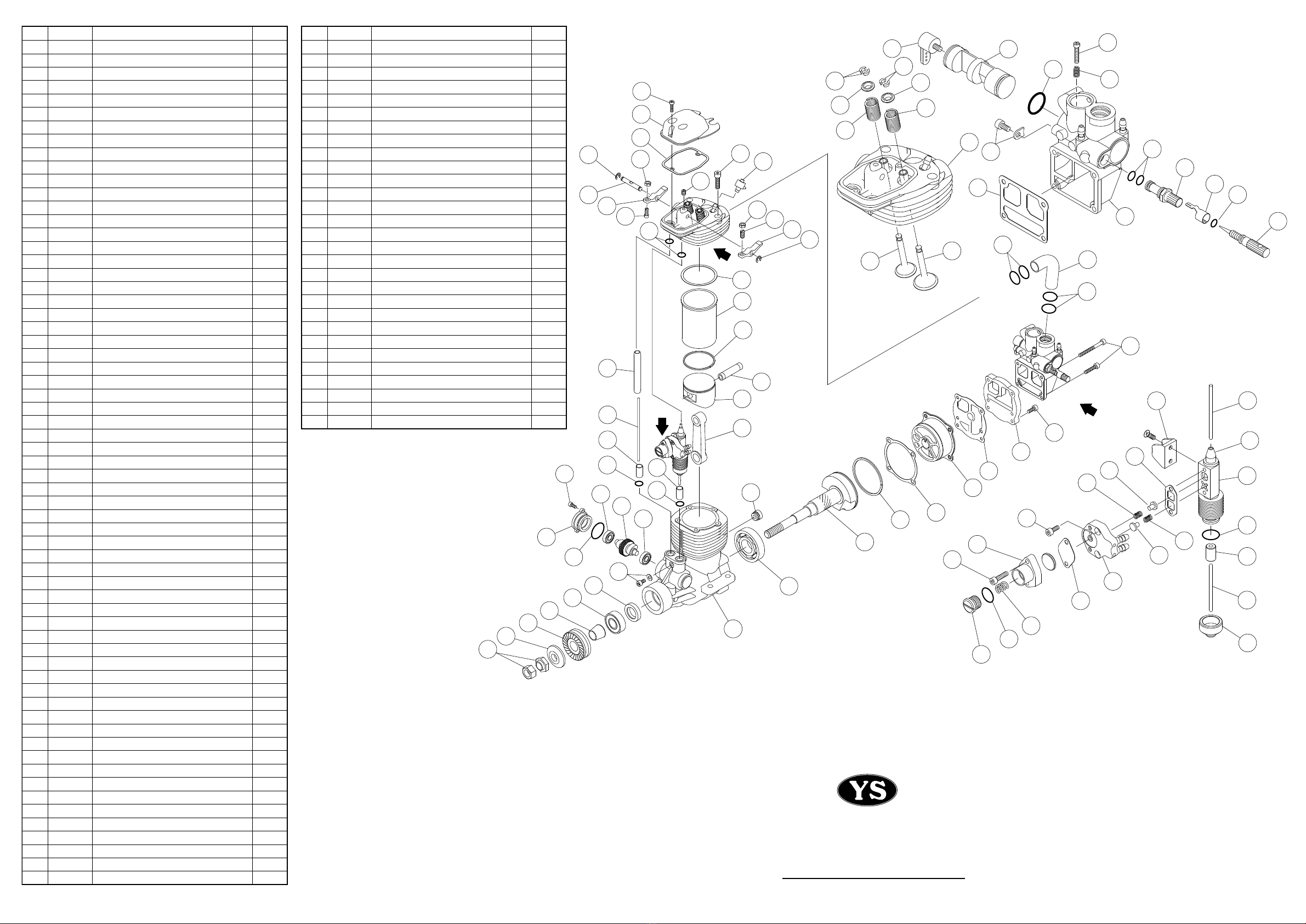

FIG 1

Fig2

DZ185zero

Bore 35mm

Stroke 31.8mm

Weight 965g ( Engine, Plug)

100g ( Ignition Box)

Displacement 30.6cc

Practical rpm 1,000~9,000rpm

OPERATOR'S MANUAL

Tappet Clearance