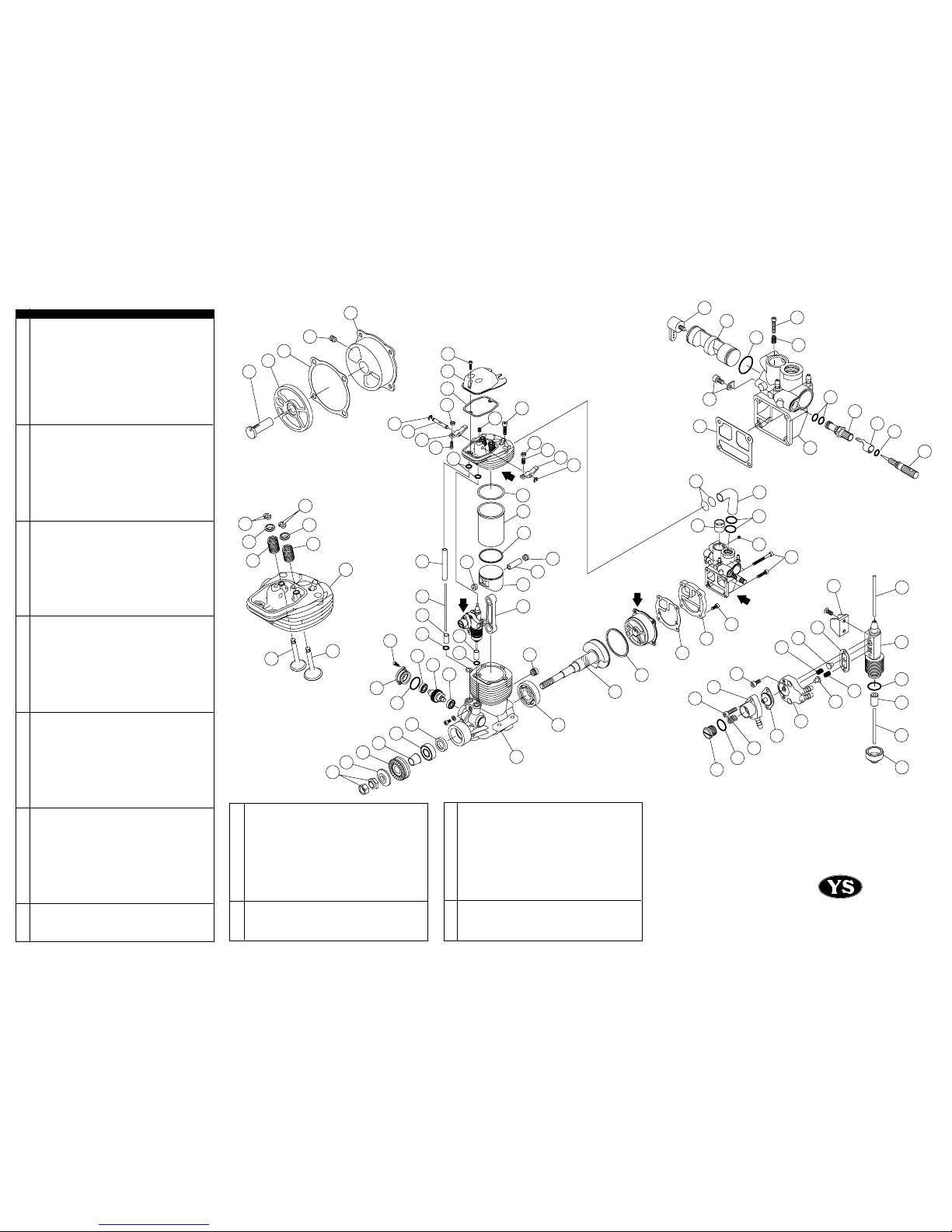

Tappet Clearance

58

Fuel Filter

High Speed Needle Valve

2563

Regulator

134

111.5

Fuel Tank Clunk

FEATURES

The DZ140 was developed for serious aerobatics competition. The

new design has been in the development stage for more than 3 years. It

differs from previous YS Engines in that it does not use a high pres-

sure fuel system but rather a true fuel pump.

*Crankcase supercharging system unique to YS 4 stroke engines

*Fuel injected

*Convenient fuel pump adjustment

*High horsepower output with long service life

GLOW PLUG

Select the most appropriate glow plug from those designed

specifically for4cycle engines. Glow plug selection greatly affects the

maximum engine output and low idle. If RPM's decrease or stop when

the booster cord is removed, replace the plug. We recommend the

YS#4 or OS Type Fplug for maximum performance.

INSTALLATION

WE RECOMMEND THAT THIS ENGINE BE MOUNTED ON A

SHOCK ABSORBING SOFT MOUNT

1Connect the engine to the tank as shown in fig.1.

The recommended fuel tank size is 500~600cc. You

must use the special clunk supplied with the engine. Please note

that with this clunk,all of the fuel cannot be used from the tank.

As soon as any part of the clunk becomes exposed, the engine

will stop due to air entering the fuel pump.

2Always use a fuel filter. We recommend YS filter.

With this filter, you must remove the cloth portion of the filter and

leave both the metal filter screens in place.

PROPELLER INSTALLATION

Due to the high output power of the 140DZ engine, it is supplied with

a double locknut system for added safety. If you use any other type

of spinner or prop nut device, make sure it is of the double nut type.

1 Mount the propeller and tighten the rear nut. Next, tighten the

front nut as shown in fig.2. The rear nut has an offset shoulder so

the front nut will secure itself to the rear nut.

2Select a good quality propeller that will allow the engine to

run at maximum speed between 7,800 to 9,000 rpm range.

We recommend sizes 15x13 to 17x12. Other prop sizes may be

used as long as the correct rpm range.

START UP

1 Always break the fuel line between the fuel filter and the tank for

filling.This will help to prevent dirt from entering the fuel pump. To

prevent flooding the engine, clamp the fuel line with a hemostat

or clip where it enters the fuel pump.

2 Open the high speed needle 2 turns from the closed position.

The engine should run very rich with the recommended fuel and

glow plug.

3

An electric starter is mandatory for starting this engine.

Attempting to hand start this engine is difficult and dangerous.

4Close the throttle to the idle position and connect the glow driver.

The engine is now ready for starting.

DO NOT ATTEMPT TO START ENGINE AT FULL THROTTLE AS

THIS IS VERY DANGEROUS. ALWAYS USE EXTREME CAUTION

WHEN ENGINE IS RUNNING.

BREAK-IN

To maximize engine performance and increase durability, please follow

this break-in procedure.

1Use the same size ( or slightly smaller ) propeller than you intend

to use in flying.

2Use a good quality fuel containing 15% to 30% nitro, and oil content

of 20% to 24%. Synthetic oil only. If you use caster oil, no more

than 2% is recommended.

DO NOT USE FOUR CYCLE FUEL DUE TO LOW OIL CONTENT.

3 After the engine has started, slowly bring the throttle up to full.

Set high speed needle so it is running at a good rich setting without

the glow driver.

4After the initial 20 minute break-in, mount the engine in the aircraft

and set the high speed to a richer than normal setting for the first

10 flights. This will help to lubricate all moving parts.

HIGH SPEED NEEDLE ADJUSTMENT

1

Adjustment of the high speed is done by the carburetor needle

valve.When the needle valve is turned clockwise, the mixture is

leaner. When it is turned counter-clockwise, the mixture is richer.

A good starting position for the high speed needle valve is 2 turns

open from the fully closed position. At this setting the engine

will be very rich and may die when you remove the glow driver.

If this happens, turn the needle valve in 1/2 turn and try again.

The final running setting for the high speed needle will be

approximately 1 to 1-1/2 turns open from fully closed.

2When the engine is started, open the throttle gradually. Next,

find the peak position ( highest RPM ) by adjusting the needle

valve. Then the needle valve should be opened approximately

1/8 _ 1/4 turns from full RPM to achieve best performance.

REGULATOR ADJUSTING

DO NOT ATTEMPT TOADJUST THE REGULATOR SCREW WITH

THE ENGINE RUNNING. STOPTHE ENGINE BEFORE ADJUSTING

THIS SCREW

The low speed adjustment is the regulator screw on the front of the

engine. Turning the screw clockwise will richen the idle mixture, and

counter-clockwise will lean the idle mixture. It is preset at the factory

but may require further adjustment depending on fuel and conditions

in your areas.

1Wait until the engine is up to operating temperature before

adjusting the idle mixture

2Close the throttle gradually to an idle ( approximately 2,200 rpm ).

Let it idle for 15 -20 seconds and then slowly advance the hrottle.

The adjustment is correct when low to high speed has a smooth

transition.

3If the engine is running rough at idle or too rich, turn the regulator

adjustment counter-clockwise to lean out the low end.

4If the engine speeds up at idle, the low speed mixture is too lean. Turn the

low speed regulator adjustment clockwise to richen the mixture.

TAPPET ADJUSTMENT

Tappet clearance is preset at the factory. Adjustment, if you needed,

should be checked after the initial break-in. For maximum performance,

valves should be checked as normal maintenance.

1Clearance adjustment should be done when the engine is cool.

2Theproper clearance should be set at not more than 0.1mm maximum.

The adjustment is achieved by loosening the lock nut ( fig.3 ) and

turning the adjustment screw. The engine must be at top dead

center on the compression stroke before any adjustments are

made. This engine runs best with the valves set at a tight setting.

If the valves are set too loose ,power will be affected.

CAM GEAR TIMING

If for some reason you have to disassemble your engine, please

follow these important steps on reassembling the cam gear.

1Remove the carburetor and backplate assembly. Notice the

impression mark or dot opposite the rod journal on the crankshaft.

This mark is to point straight down or lined up with the outer case

seam line at the bottom

2 Reinstall the cam with the dot facing you and pointing slightly to

the left. This will allow the cam to turn to the right when properly

installed. The dot should be pointing straight up when cam is fully

installed. Reinstall cam cover and timing is now set.

FUEL PUMP

I

f you must disassemble the fuel pump to change the diaphragm or to

clean, take care that the valves and springs are replaced in exactly the

same manner in which they were removed. Do not disassemble the

pump needlessly. Use care with filtering your fuel and keeping the

entire fuel system in good working order. It will help to prevent fuel

pump problems.

VENTURI RESTRICTOR

DZ140 is equipped with a removable venturi restrictor for increased

fuel economy with only a slight decrease in performance. With the

restrictor in, the RPM drop will be 300 to 400 rpm.

COOLING

In some aircraft installations, cooling of the engine and fuel pump is

extremely critical for optimum performance. Ducting which forces

incoming air around the cylinder head is recommended. Be sure to

provide adequate size inlets and outlets for air traveling through the

cowling.

IMPORTANT

Silicone rubber is used in the YS engines. Only use glow fuel or

methanol forcleaning. Gasolineand other volatilesolvents will damage the

silicone if used. Do not use petroleum based oils as after-run

lubricants.

OPERATOR’S MANUAL

DZ140

SPECIFICATIONS

Bore 32mm

Stroke 29.0mm

Displacement 23cc

Weight 920g

Practical rpm 2,000 -11,000rpm

fig.1

fig.2

fig.3

Front Nut Rear Nut