ADA-WA 1; ADA-WA 4

5

ba76071e01 02/2012

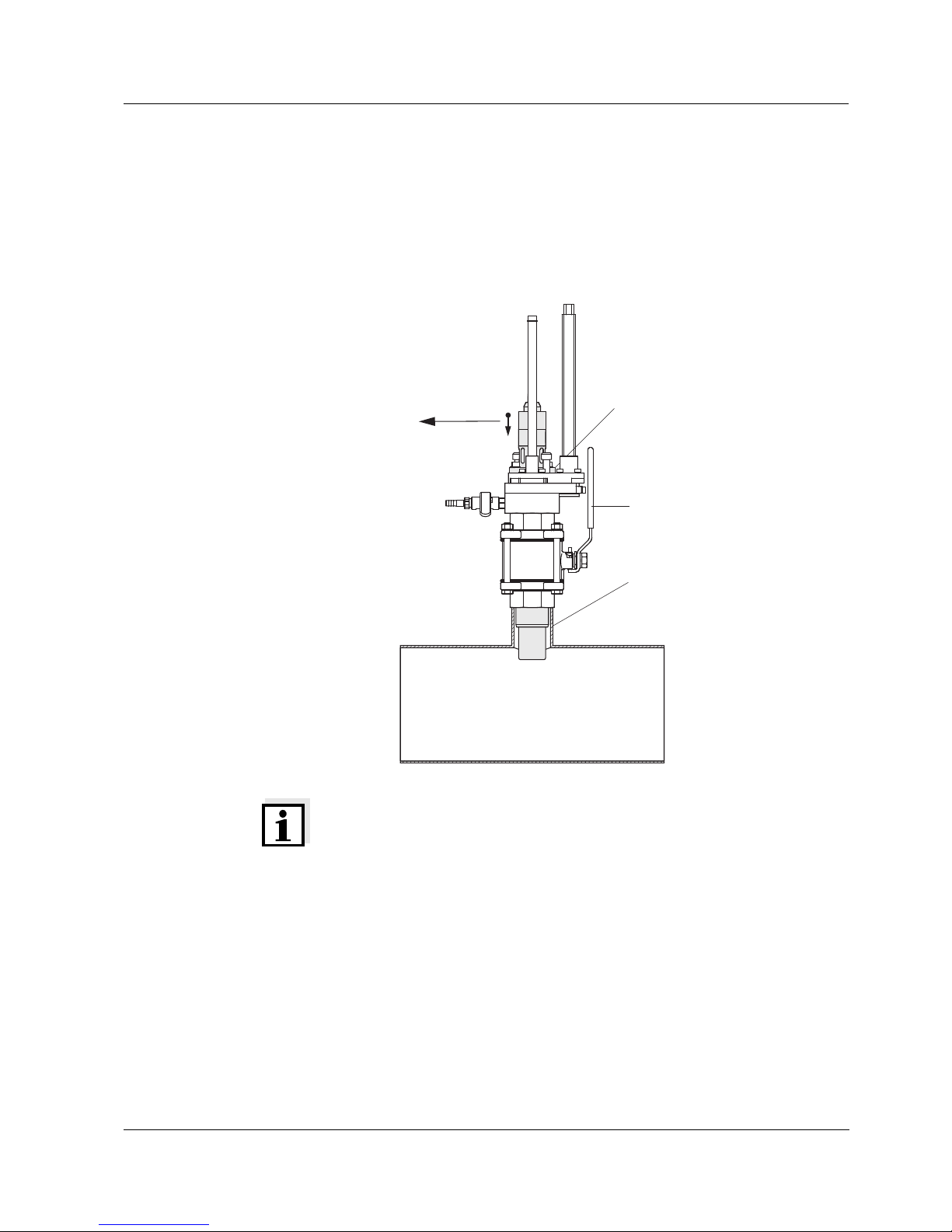

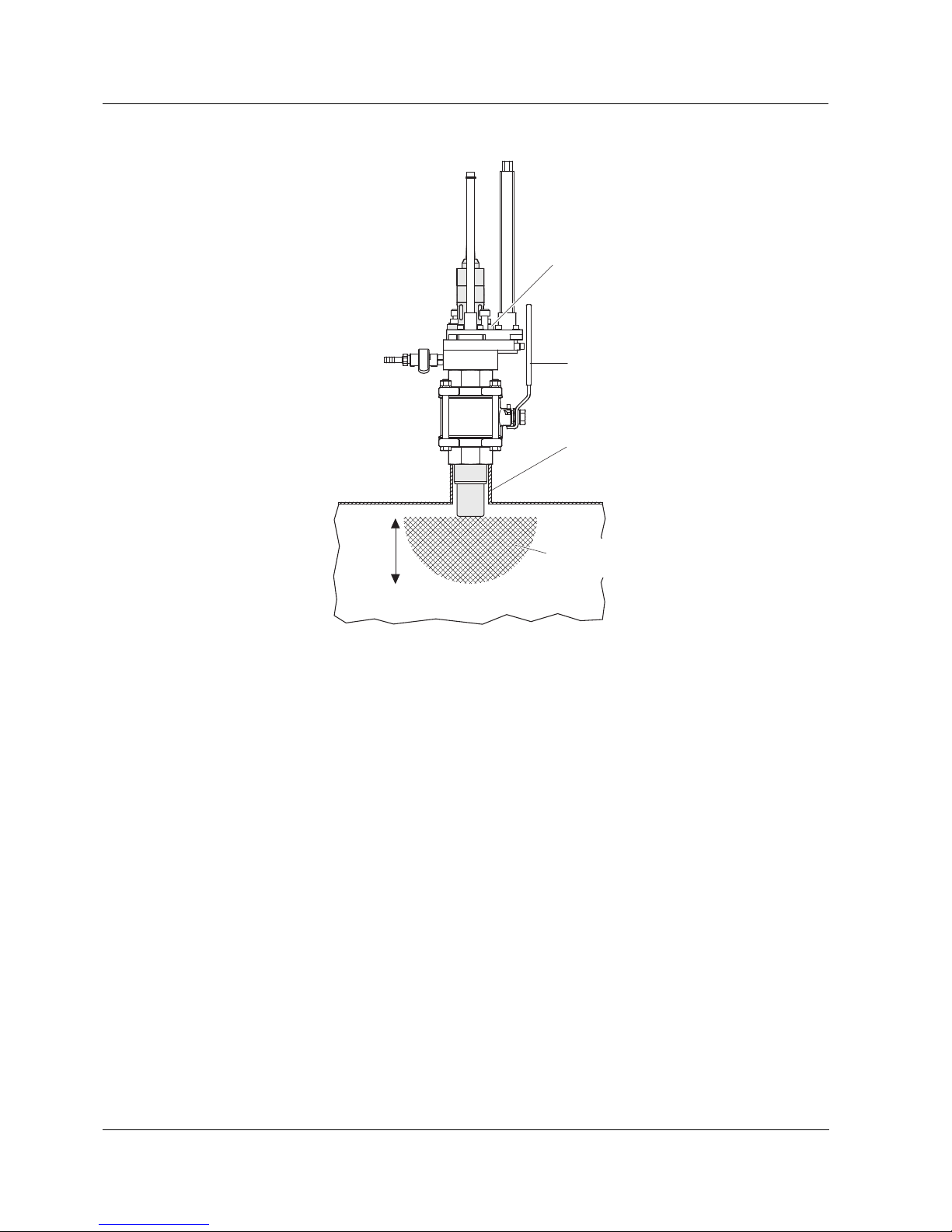

Overview of the recommended installation locations (continued)

Sensor type Installation

location

(see diagram

on page 3)

Advantages (+) /

Disadvantages (-)

Conclusion / Comments

VisoTurb 700 IQ,

ViSolid 700 IQ

Note:

Please note the

special installation

recommendations

in the following

section.

A + Optimum flow of the sapphire disc

so there is no capture of air bub-

bles or large particles in front of

the sensor

- Susceptible to fibers getting

caught

- Risk of damage from stones and

abrasive particles

Optimum installation location

for measuring media without

contamination from fibers,

stones, or abrasive particles.

C + No risk of contamination by long fi-

bers

+ Low risk of damage from stones

and abrasive particles

- Susceptible to the capture of air

bubbles or large particles in front

of the sapphire disc (turbulence

effect)

In the case of contamination by

fibers, less prone to contamina-

tion than A.

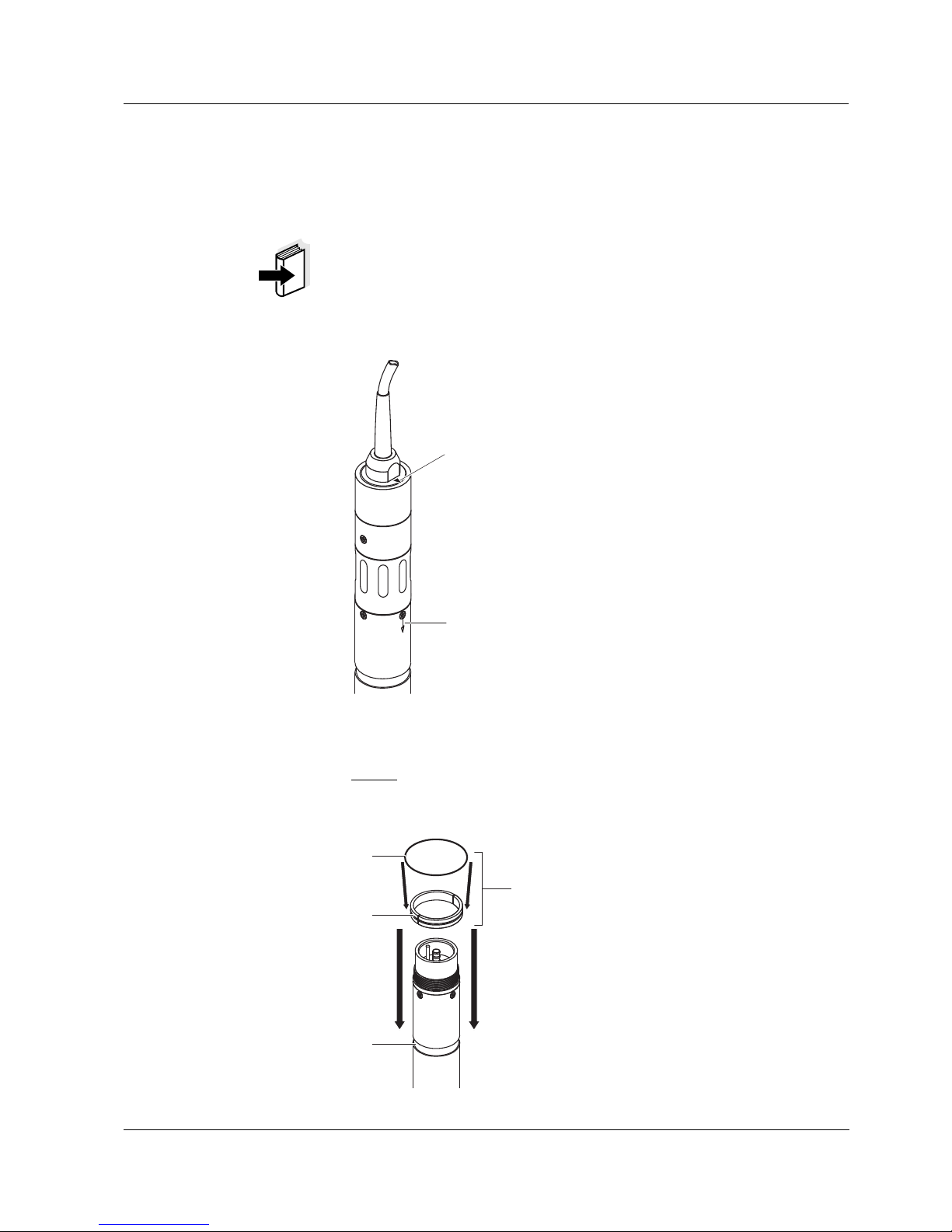

B + Good flow of the sapphire disc, so

there is no interference from air

bubbles or large particles in front

of the sensor

- Risk of light reflections in narrow

containers

Good possibility in sufficiently

large containers or high values

of turbidity/total suspended sol-

ids.