Introduction:

The Isaac HD Multi-Function Leak Tester is the newest product from Zaxis, designed to meet

today’s quality assurance demands.

The compact size of the Isaac enables it to be used in close proximity to fixtures and

operators utilizing a small footprint of bench top space. By reducing the internal and connection

volume the test sensitivity increases and test times can be decreased. The small internal volume

combined with integrated sensors and a 24bit analog to digital converter allow Zaxis to offer a

leak tester with the highest sensitivity on the market. The Isaac is available for pressure or

vacuum decay, mass flow, burst, pressure cracking, sealed component (chamber), and custom

test sequencing applications. The Isaac can be configured from one to four test channels in a

sequential or concurrent configuration depending upon applications.

This guide covers the standard Isaac HD and i-Kit HD leak testers. All of

the current functions and features are described in this manual. Your

tester could differ in installed features. Check the additional test types

section of this guide for application notes about your tester.

Safety and Emissions:

Operating Environment Conditions:

Indoor use only

▪Operating temperature range: 5-40° C

▪Maximum relative humidity: 80%

▪Main supply voltage: 120 V +/-10%, 2A ~ 60 Hz

Or 230 V +/-10%, 2A ~ 50Hz

▪Altitude: up to 2000 meters

▪Supply Air Pressure: 8.3 bar max. (unless otherwise specified)

Supply air must be clean and dry.

(10 micron filtration minimum, 5 micron recommended)

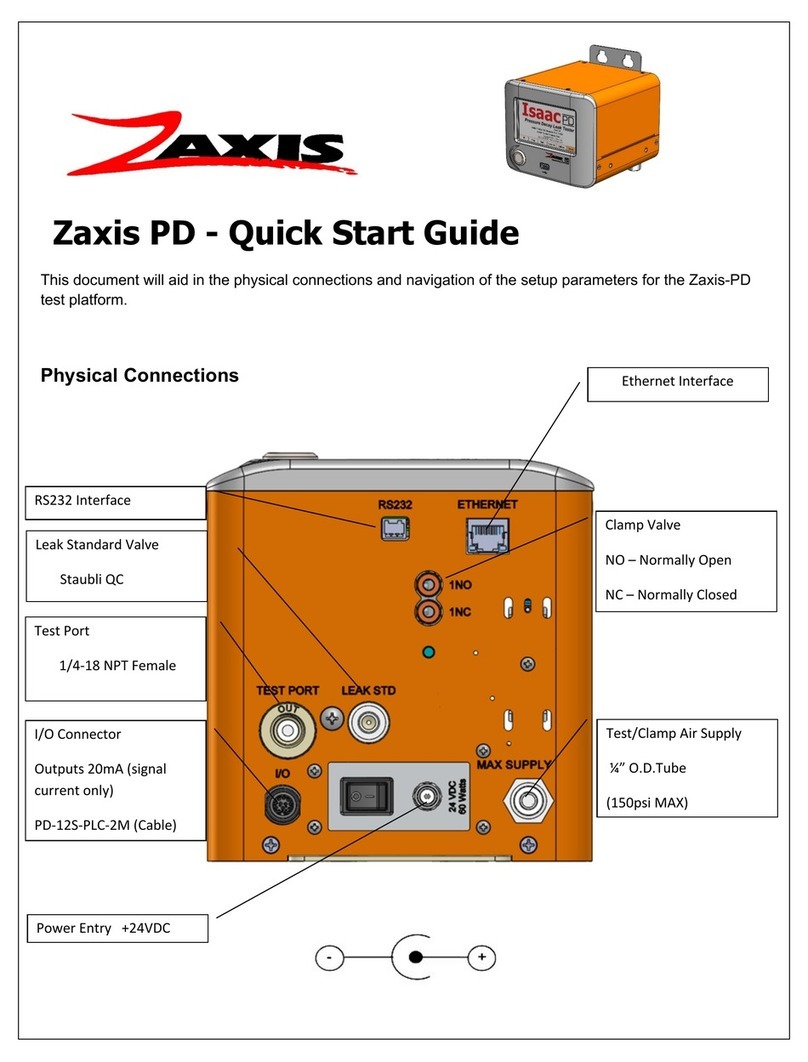

Physical Description: