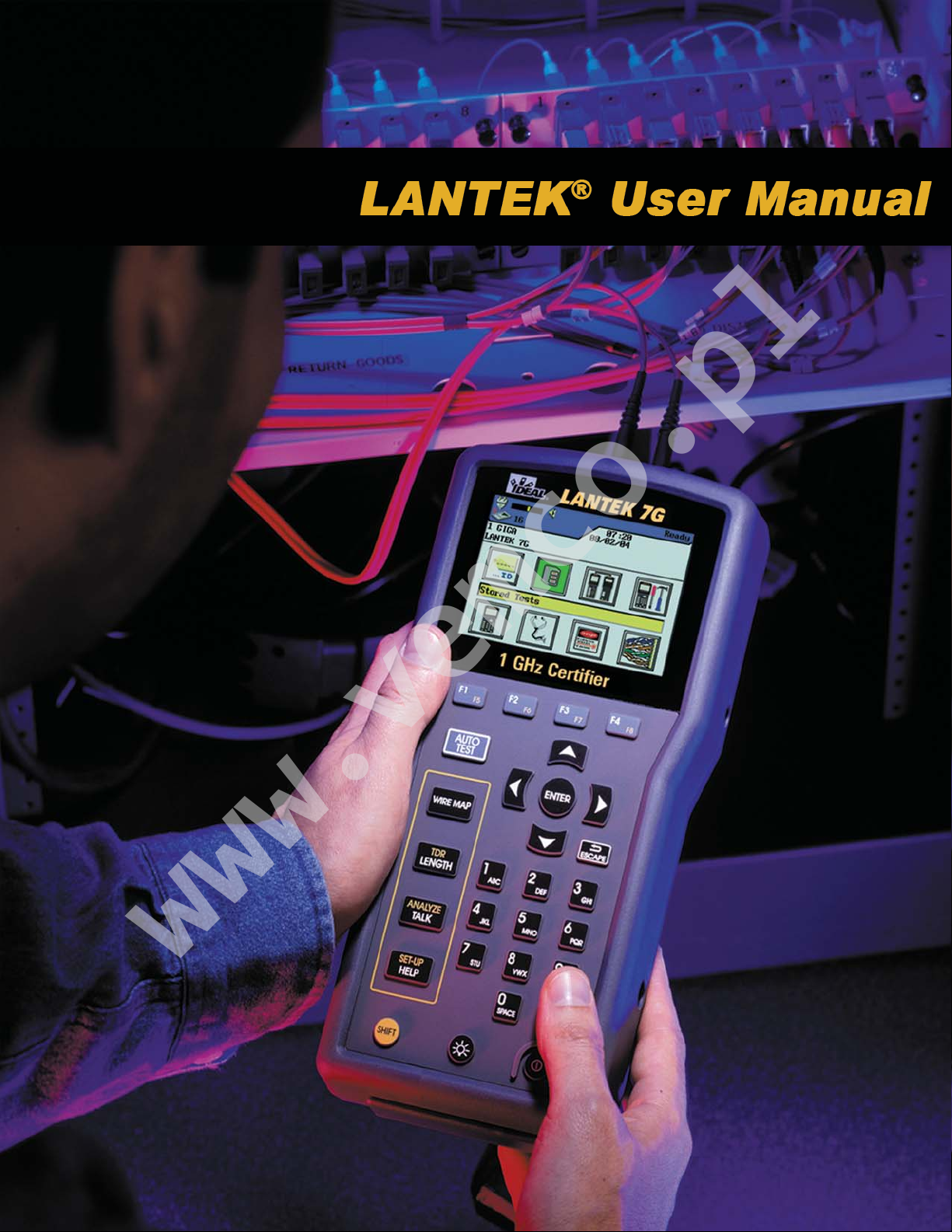

IDEAL INDUSTRIES STANDARD WARRANTY POLICY

IDEAL INDUSTRIES warrants that all LANTEK Products manufactured or procured by

IDEAL INDUSTRIES conform to IDEAL INDUSTRIES’ published specifications and are

free from defects in materials and workmanship for a period of two (2) years from the

date of delivery to the original Buyer, when used under normal operating conditions

and within the service conditions for which they are designed. This warranty is not

transferable and does not apply to used or demonstration products.

The obligation of IDEAL INDUSTRIES arising from a Warranty claim shall be limited to

repairing, or at its option, replacing without charge, any assembly or component

(except batteries and cable adapters), which in IDEAL INDUSTRIES’ sole opinion

proves to be defective within the scope of the Warranty. In the event Ideal Industries

is not able to modify, repair or replace nonconforming defective parts or components

to a condition as warranted within a reasonable time after receipt thereof, Buyers shall

receive credit in the amount of the original invoiced price of the product.

IDEAL INDUSTRIES must be notified in writing of the defect or nonconformity within

the Warranty period and the affected Product returned to IDEAL INDUSTRIES’ factory,

designated Service Provider, or Authorized Service Center within thirty (30) days after

discovery of such defect or nonconformity. Buyer shall prepay shipping charges and

insurance for Products returned to IDEAL INDUSTRIES or its designated Service

Provider for warranty service. IDEAL INDUSTRIES or its designated Service Provider

shall pay costs for return of Products to Buyer.

IDEAL INDUSTRIES shall have no responsibility for any defect or damage caused by

improper storage, improper installation, unauthorized modification, misuse, neglect,

inadequate maintenance, accident or for any Product which has been repaired or

altered by anyone other than IDEAL INDUSTRIES or its authorized representative or

not in accordance with instructions furnished by IDEAL INDUSTRIES.

The Warranty described above is Buyer’s sole and exclusive remedy and no other

warranty, whether written or oral, expressed or implied by statute or course of dealing

shall apply. IDEAL INDUSTRIES specifically disclaims the implied warranties of

merchantability and fitness for a particular purpose. No statement, representation,

agreement, or understanding, oral or written, made by an agent, distributor, or

employee of IDEAL INDUSTRIES, which is not contained in the foregoing Warranty will

be binding upon IDEAL INDUSTRIES, unless made in writing and executed by an

authorized representative of IDEAL INDUSTRIES. Under no circumstances shall IDEAL

INDUSTRIES be liable for any direct, indirect, special, incidental, or consequential

damages, expenses, or losses, including loss of profits, based on contract, tort, or any

other legal theory.

IDEAL INDUSTRIES recommends that the user review all of the information in

Appendix A, SAFETY PRECAUTIONS, prior to using the LANTEK tester.