3 - EN

Table of Contents

Preface 1

1 introduction .........................................................................................................................................1

1.1 Guarantee and liability..................................................................................................................... 1

1.1.1 Guarantee conditions.............................................................................................................................1

1.1.2Liability...................................................................................................................................................1

1.2 Safety

........................................................................................................................................... 2

1.2.1 Safety regulations ...............................................................................................................................2

1.2.2 Safety provisions and measures .........................................................................................................2

1.2.3 Pictograms used .................................................................................................................................2

2 For the installer...................................................................................................................................................3

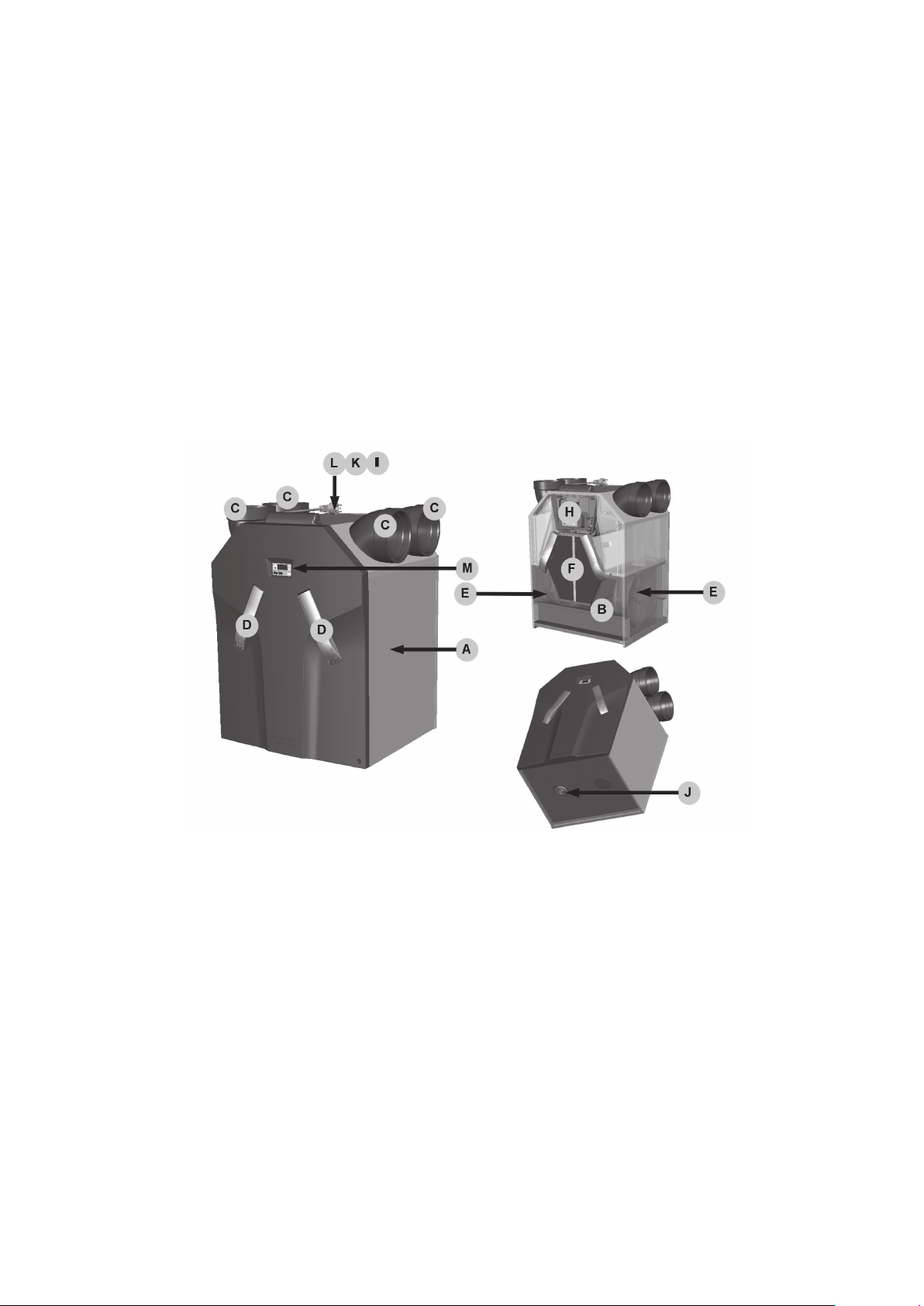

2.1 ComfoAir configuration .................................................................................................................................3

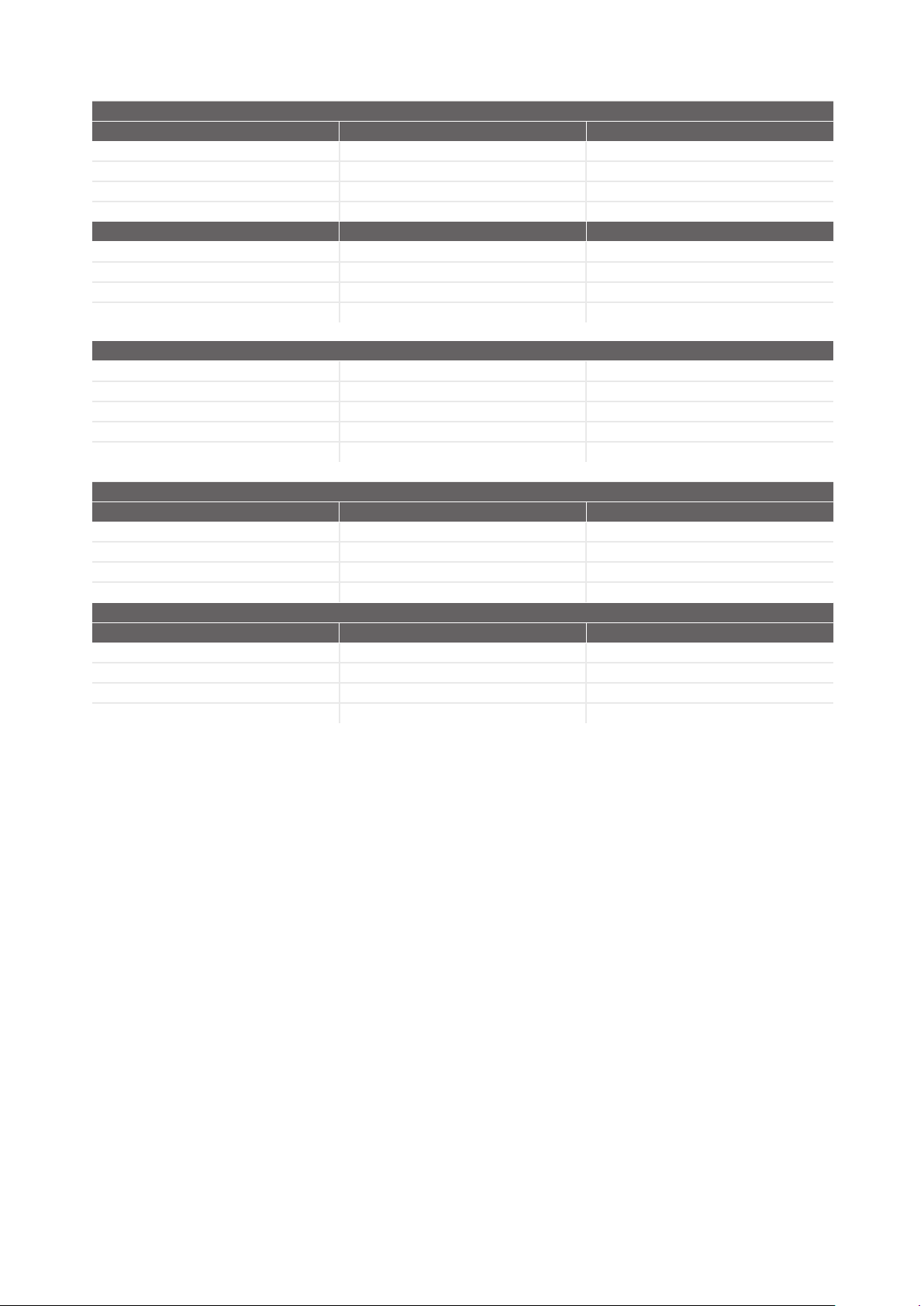

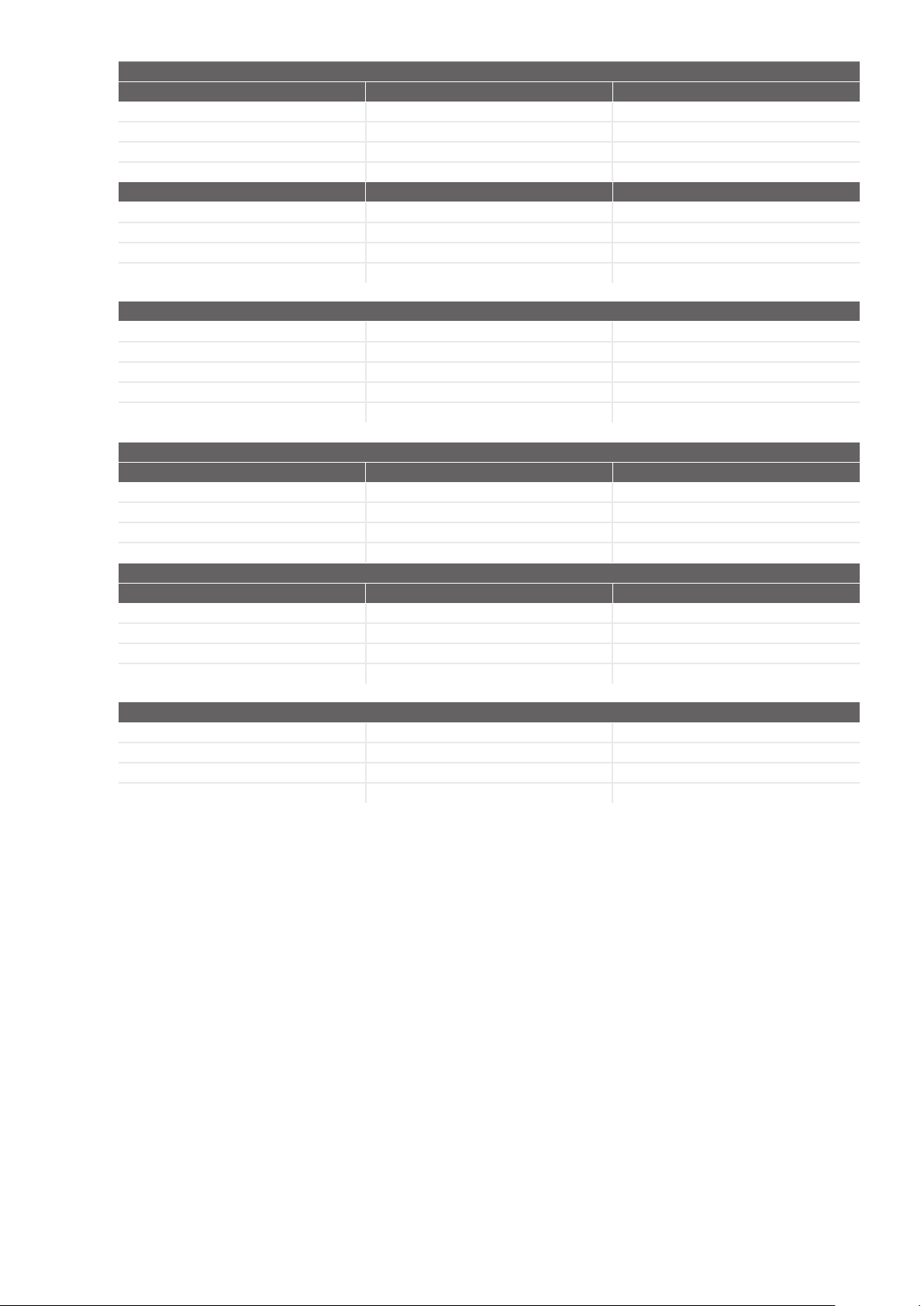

2.2 Technical specifications ................................................................................................................................4

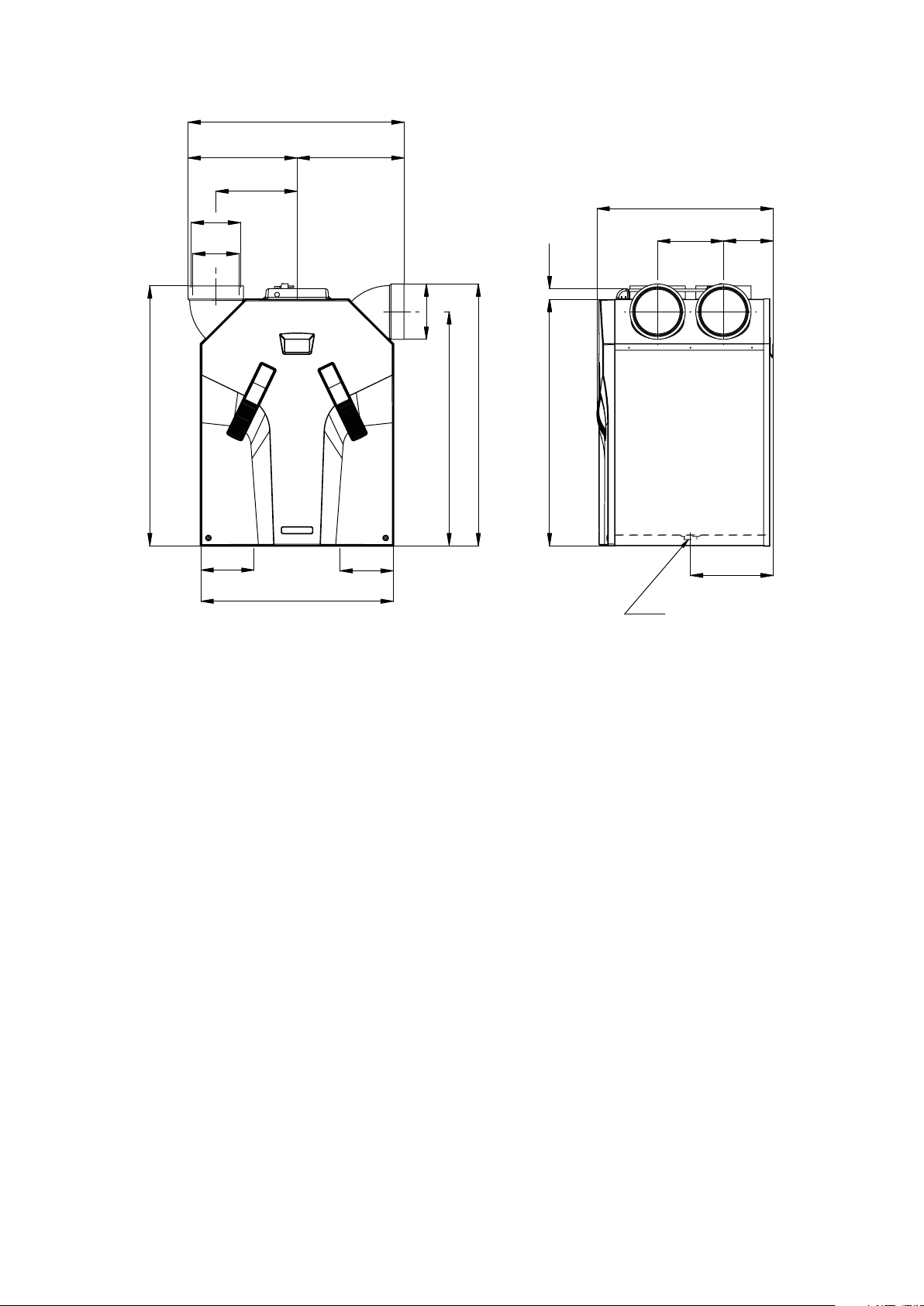

2.3 Dimension sketch ..........................................................................................................................................6

2.4 Installation conditions ...................................................................................................................................7

2.5 Installation of the ComfoAir ...........................................................................................................................7

2.5.1 Transport and unpacking ....................................................................................................................7

2.5.2 Checking the delivery..........................................................................................................................7

2.6 Mounting of the ComfoAir .............................................................................................................................7

2.6.1 Mounting on the wall...........................................................................................................................7

2.6.2 Connection of the air ducts.................................................................................................................8

2.6.3 Connection of the condensation drain ................................................................................................8

2.7 Commissioning the ComfoAir ........................................................................................................................9

2.7.1Display on the unit .................................................................................................................................9

2.7.2 P menus for the user......................................................................................................................... 10

2.7.3 P menus for the installer ...................................................................................................................12

2.8 Programming air specifications ...................................................................................................................15

2.9 Maintenance by the installer........................................................................................................................16

2.9.1 Inspecting and cleaning the heat exchanger.....................................................................................16

2.9.2 Inspecting and cleaning the fans ...................................................................................................... 17

2.9.3 Inspecting and cleaning the preheater element filter......................................................................... 17

2.10 Malfunctions................................................................................................................................................18

2.10.1 Malfunction alerts on digital operating devices.................................................................................18

2.10.2 3-position switches with malfunction indicator .................................................................................18

2.10.3 What to do in the event of a malfunction / Trouble shooting ............................................................. 19

2.10.4 Malfunctions (or problems) without alarms ......................................................................................25

2.11 Service parts ...............................................................................................................................................26

2.12 Wiring diagram: ComfoAir 350 Basic – LEFT-HAND version........................................................................27

2.13 Wiring diagram: ComfoAir 350 Basic – RIGHT-HAND version .....................................................................28

2.14 EEC declaration of conformity ....................................................................................................................29