AEROLYTE 6060A and 7070A G2 PRESSURE CABINETS Page 3

© 2016 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 27789 Rev. A, 10/16

1910.169 refers to the ASME code when describing the

necessity of pressure relief valves on compressed air

equipment. DO NOT operate blast machines with air

compressors that are not equipped with properly-

functioning pressure relief valves.

(1) American Society of Mechanical Engineers, Boiler and Pressure

Vessel Code, Section VIII, Division 1,

(2) Occupational Safety and Health Administration, 29 CFR 1910, 169.

1.5.5 The piping on the blast machine does include a

relief valve that set to vent at 65 psi. Its only purpose is

to serve as an audible signal that pressure is above

normal pressure settings for non-aggressive media and

delicate substrates.

1.5.6 When the cabinet is setup, the blast machine is

ready to blast by actuating the foot pedal. Pressing the

foot pedal opens the normally closed main inlet

regulator, and closes the normally open outlet valve.

The incoming air pressurizes the blast machine, and

blasting begins. When pressure on the foot pedal is

released, the blast machine depressurizes, and blasting

stops.

1.6 Nozzle Options

1.6.1 Unless otherwise specified at time of order,

cabinets are shipped with a 5/16" orifice, silicon carbide

lined, short venturi nozzle. Optional 1/4" or 3/8" orifice

nozzles are also available. 1/4" nozzles should be used

only when the air supply is limited. Low nozzle velocity

and non-aggressive media make 1/4" nozzles

ineffective except for loose adhering coatings and low

production dry stripping tasks. The chart in Figure 2

shows cfm consumption when nozzles are new. Large

nozzles (3/8" and in some cases larger), should be

limited to tough stripping jobs. High nozzle velocity and

high pressure will cause rapid media breakdown.

COMPRESSED AIR CONSUMPTION *(cfm)

Nozzle AIR PRESSURE (psi)

Orifice 20 25 30 35 40 45

1/4" 25 29 32 36 40 43

5/16" 41 47 53 59 65 71

3/8" 57 66 75 83 92 100

* Figures are approximate and for reference only,

and may vary for different working conditions.

Several variables, including media flow and nozzle

wear affect cfm consumption.

Figure 2

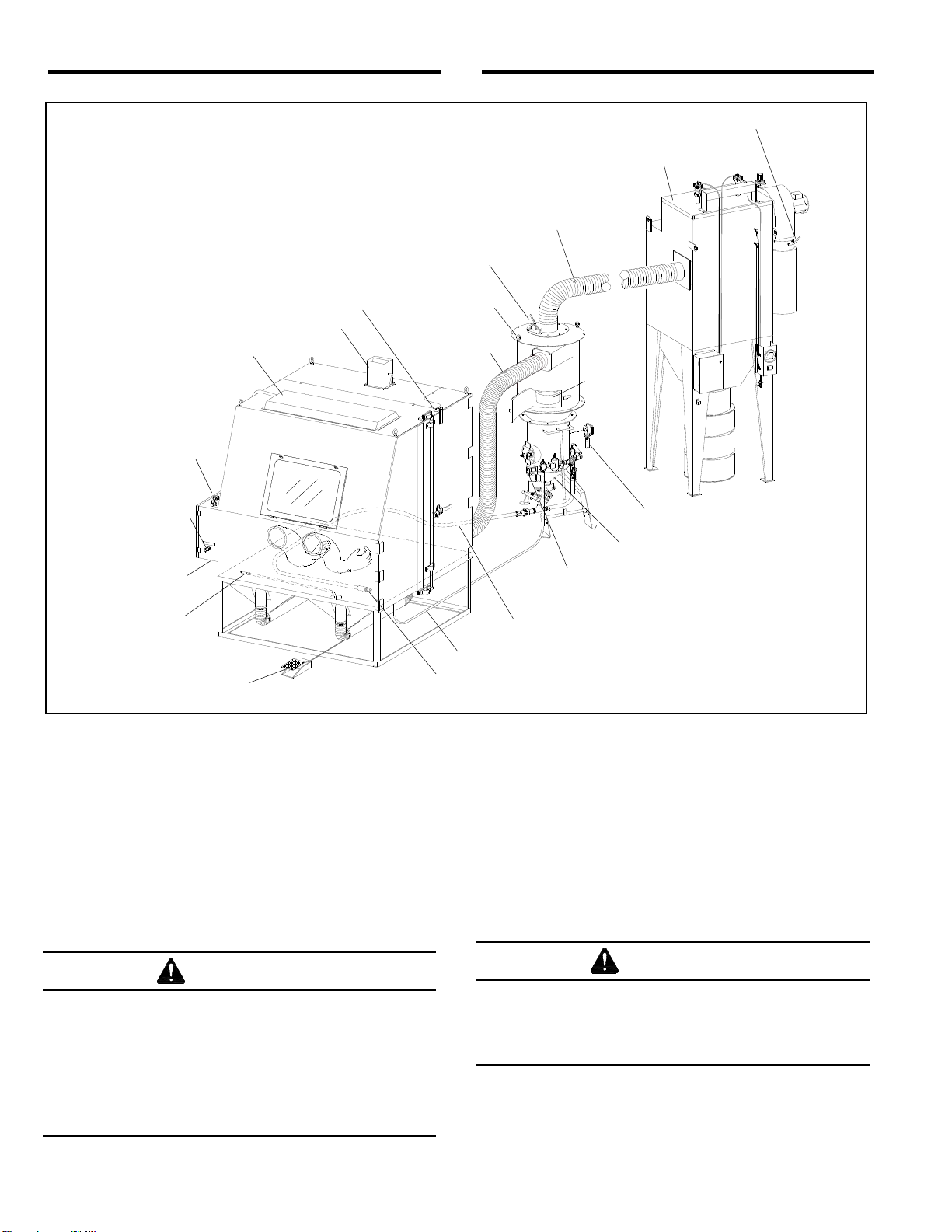

1.7 Dust Collector Options

1.7.1 RPH Dust Collector: The RPH-2 is the

standard dust collector unless another collector is

specified at the time the order is placed. Refer to RPH

dust collector manual number 21449.

1.7.2 HEPA (high-efficiency particulate air) Filter:

HEPA after-filters provide additional filtration and must

be used with a reverse-pulse cartridge collectors when

removing lead coatings or any other toxic materials.

HEPA filters are listed under Optional Accessories in

Section 9.1.

1.8 Blasting Media

1.8.1 Aerolyte Dry Stripping Cabinets are designed to

utilize plastic media and other lightweight non

aggressive reusable media specifically manufactured for

dry stripping. The usable media size range depends on

the nozzle orifice size and reclaimer cleaning rate.

Several factors affecting the reclaimer cleaning rate

include: reclaimer size, air pressure, media/air mixture,

media breakdown, contamination of parts being

cleaned, and humidity.

1.9 Compressed Air Requirements

1.9.1 The size of the compressor required to operate

the cabinet depends on the size of the nozzle and

stripping pressure. See the air consumption table in

Figure 2. Unless specified otherwise, cabinets are

supplied with a 5/16" orifice nozzle. The table in Figure

2 shows air consumption of nozzles when new; it does

not show the recommended compressor size. When the

nozzles are worn, they will consume 70% to 80% more

air. Consult with a compressor supplier for a suggested

compressor size based on the air consumption.

NOTE: A separate air line is required for the optional

reverse-pulse dust collector.

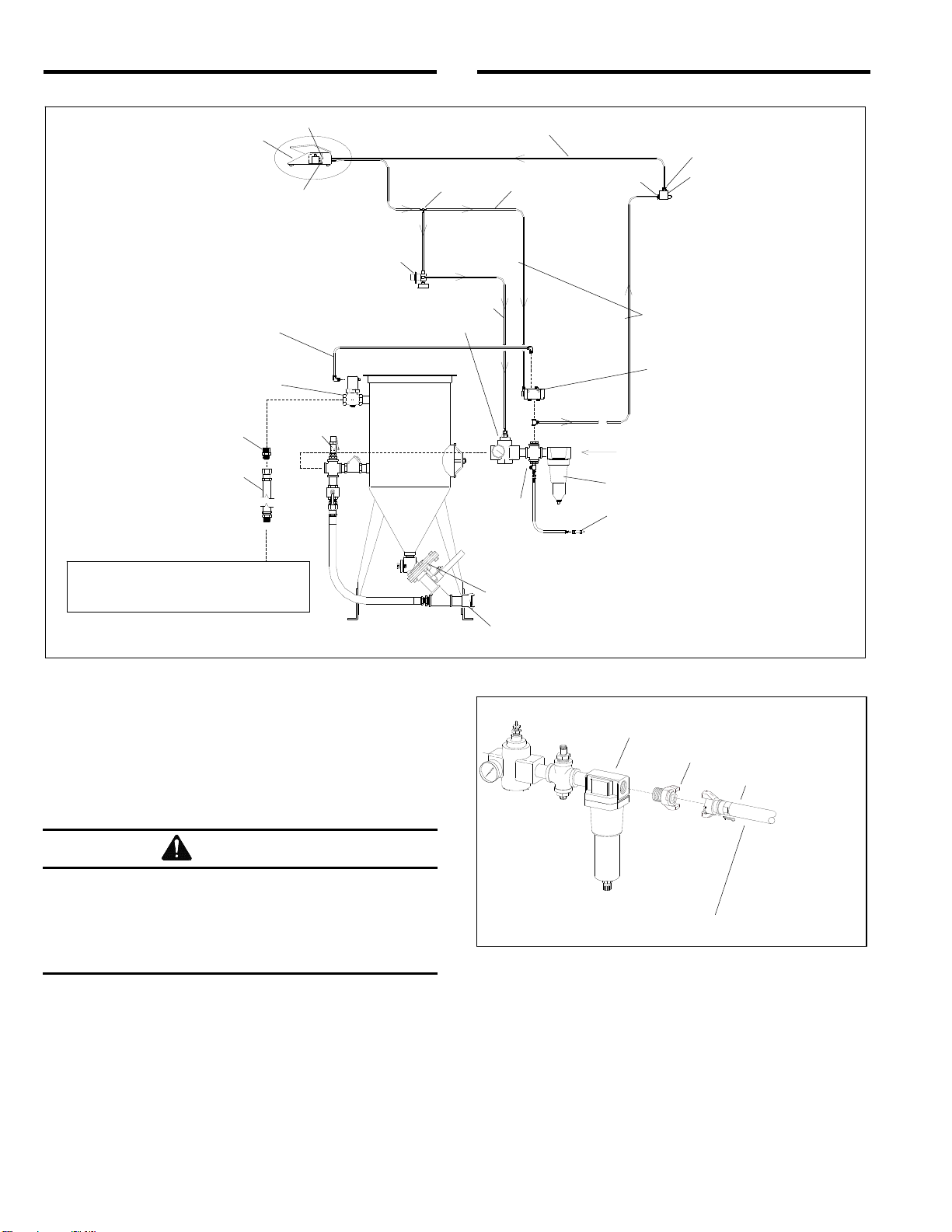

1.9.2 The air filter at the blast machine inlet, removes

condensed water from compressed air. The filter

automatically drains when moisture fills the bowl to a

certain level. Its use is especially important in areas of

high humidity, or when fine-mesh media are used.

Moisture causes media to clump and prevents free flow

through the metering valve. If the filter does not remove

enough moisture to keep media dry and flowing, it may

be necessary to install an air dryer or aftercooler in the

air supply line.