PULSAR® PLUS III-S, III-S6, and VI-S SUCTION BLAST CABINETS Page 2

© 2021 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 30421

Reclaimer Static Pressure (exhaust damper) ............ 5.4

Cabinet Height – Lift Legs .......................................... 5.5

Door Interlocks ........................................................... 5.6

Dustbin Interlock ......................................................... 5.7

Dust-Collector Pulse Pressure ................................... 5.8

Digital Pulse-Control Timer ........................................ 5.9

Operating principles ............................................. 5.9.1

Resetting pulse OFF time .................................... 5.9.2

Reset pulse ON time to factory setting ............... 5.9.3

Reset timer functions to factory “A” setting .......... 5.9.4

Reset timer subranges to factory settings ............ 5.9.5

Cabinet Air-Inlet Damper .......................................... 5.10

Using the Manometer to Set Static Pressure ............ 5.11

PREVENTIVE MAINTENANCE ................................. 6.0

Inspection Notes ......................................................... 6.1

Daily Inspection and Maintenance Before Blasting ..... 6.2

Check media level ................................................ 6.2.1

Inspect reclaimer debris screen and door gasket ... 6.2.2

Drain compressed-air filter ................................... 6.2.3

Inspect dustbin ..................................................... 6.2.4

Daily Inspection During Blasting ................................ 6.3

Inspect cabinet for dust leaks .............................. 6.3.1

Check exhaust air for dust ................................... 6.3.2

Drain pulse reservoir (at end of day) ..................... 6.3.3

Weekly Inspection and Maintenance Before Blasting ... 6.4

View-window cover lens ....................................... 6.4.1

Gloves .................................................................. 6.4.2

BNP® gun assembly ............................................. 6.4.3

Media hose ........................................................... 6.4.4

Dust-collector’s inline filter ................................... 6.4.5

Weekly Inspection During Blasting ............................. 6.5

Flex hoses ............................................................ 6.5.1

Monthly Inspection and Maintenance ......................... 6.6

Reclaimer wear plate and liners ........................... 6.6.1

Additional Dust-Collector Cartridge Pulsing ............... 6.7

SERVICE MAINTENANCE ......................................... 7.0

Gloves Replacement ................................................... 7.1

Quick-Change Gloves and Glove Mounts ................... 7.2

BNP® Gun Assembly ................................................... 7.3

View-Window Cover Lens ........................................... 7.4

View-Window Replacement ........................................ 7.5

Window-Gasket Replacement ..................................... 7.6

Window-Frame Removal ............................................. 7.7

LED Light Assembly .................................................... 7.8

Tube-Lock Fittings ....................................................... 7.9

Servicing Pneumatic Inlet Assembly ......................... 7.10

Replacing Reclaimer Wear Plate .............................. 7.11

300 cfm reclaimer with wielding-on top ............... 7.11.1

600 cfm reclaimer with bolt-on top ...................... 7.11.2

Replacing or Installing Rubber Reclaimer Liners ...... 7.12

Removing or Replacing Reclaimer Inlet Baffle ......... 7.13

Replacing Filter Cartridge .......................................... 7.14

Seasoning Filter Cartridge ......................................... 7.15

Clean Dust-Collector’s Inline Filter ............................ 7.16

Clean Dust-Collector’s Snubber Fittings ................... 7.17

Diaphragm Pulse Valve ............................................. 7.18

TROUBLESHOOTING – PNEU. and MECHANICAL ..... 8.0

Poor visibility/dusty media .......................................... 8.1

Abnormally high media consumption .......................... 8.2

Reduction in blast cleaning rate ................................. 8.3

Plugged nozzle ........................................................... 8.4

Media bridging ............................................................ 8.5

Media surge ................................................................ 8.6

Blockage in media hose ............................................. 8.7

Poor suction in media hose ........................................ 8.8

Air only (no media) from nozzle .................................. 8.9

Blowback through media hose ................................. 8.10

Blasting does not begin when foot pedal is pressed ....... 8.11

Blasting continues after releasing foot pedal ............ 8.12

Media buildup in cabinet hopper ............................... 8.13

Static shocks ............................................................. 8.14

Dust or media leaking from cabinet .......................... 8.15

Dust leaking from dust collector ............................... 8.16

Dust collector does not pulse ................................... 8.17

Dust-collector pulse is steady stream of air .............. 8.18

Dust-collector differential gauge is consistently high ... 8.19

TROUBLESHOOTING - ELECTRICAL ........................ 9.0

Green pushbutton does not illuminate ......................... 9.1

Dust-collector exhauster motor does not start ............ 9.2

Lift legs do not move .................................................. 9.3

Blasting does not begin when foot pedal is pressed ........ 9.4

Foot pedal not working ............................................... 9.5

Blast solenoid valve not working ................................ 9.6

Poor visibility/dusty media .......................................... 9.7

Cabinet LED light does not turn ON ........................... 9.8

ACCESSORIES and REPLACEMENT PARTS ...... 10.0

Optional Accessories ................................................ 10.1

Pulsar III-S and VI-S Cabinet Assembly ................... 10.2

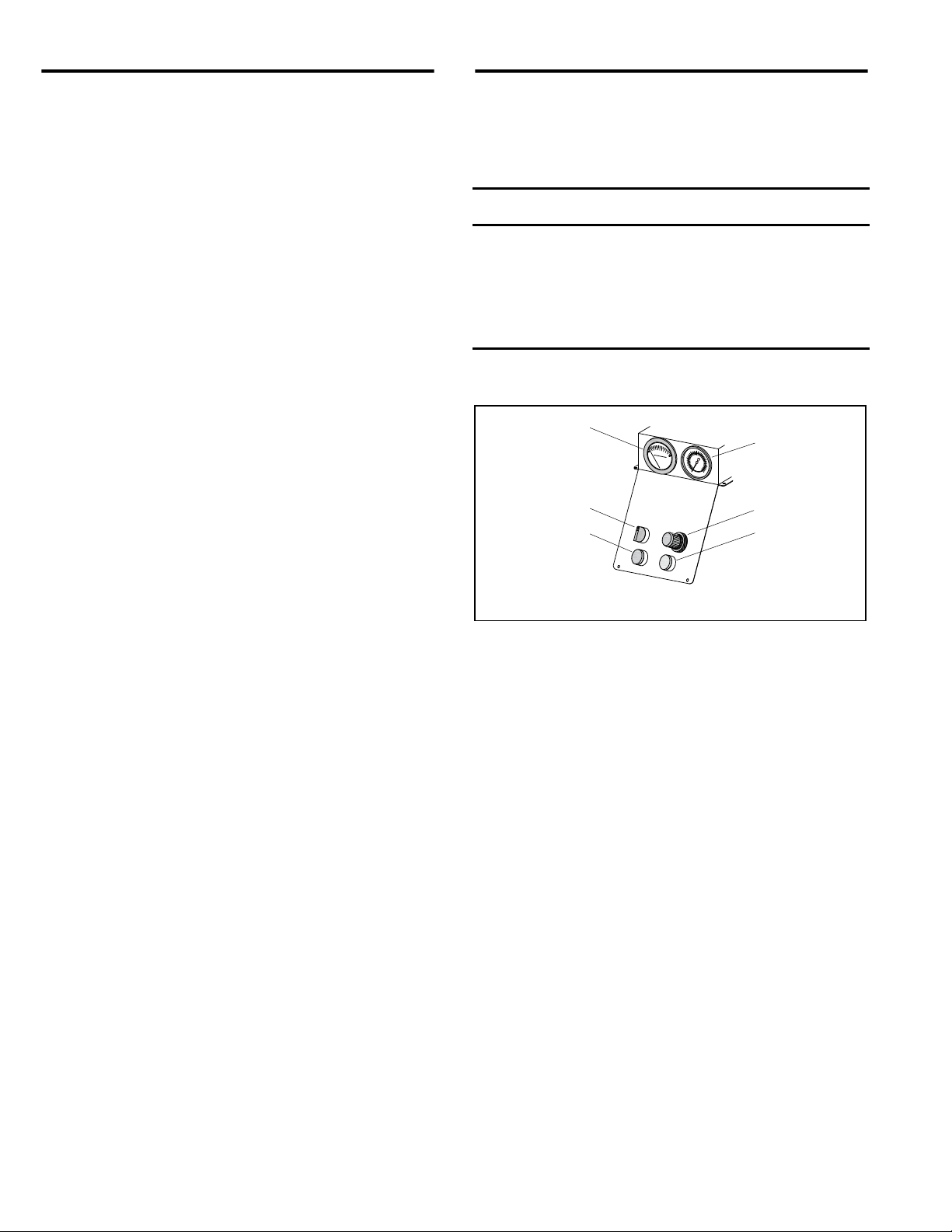

Cabinet Control Console .......................................... 10.3

View Window Assembly ........................................... 10.4

Metering Valve .......................................................... 10.5

Gloves and Glove Mounts ........................................ 10.6

LED Light Assembly ................................................. 10.7

BNP® Gun and Feed Assembly ................................ 10.8

Pneumatic Controls and Parts .................................. 10.9

Reclaimer, Pulsar III 300 CFM ............................... 10.10

Reclaimer, Pulsar VI, 600 CFM .............................. 10.11

Dust Collector Assembly ........................................ 10.12

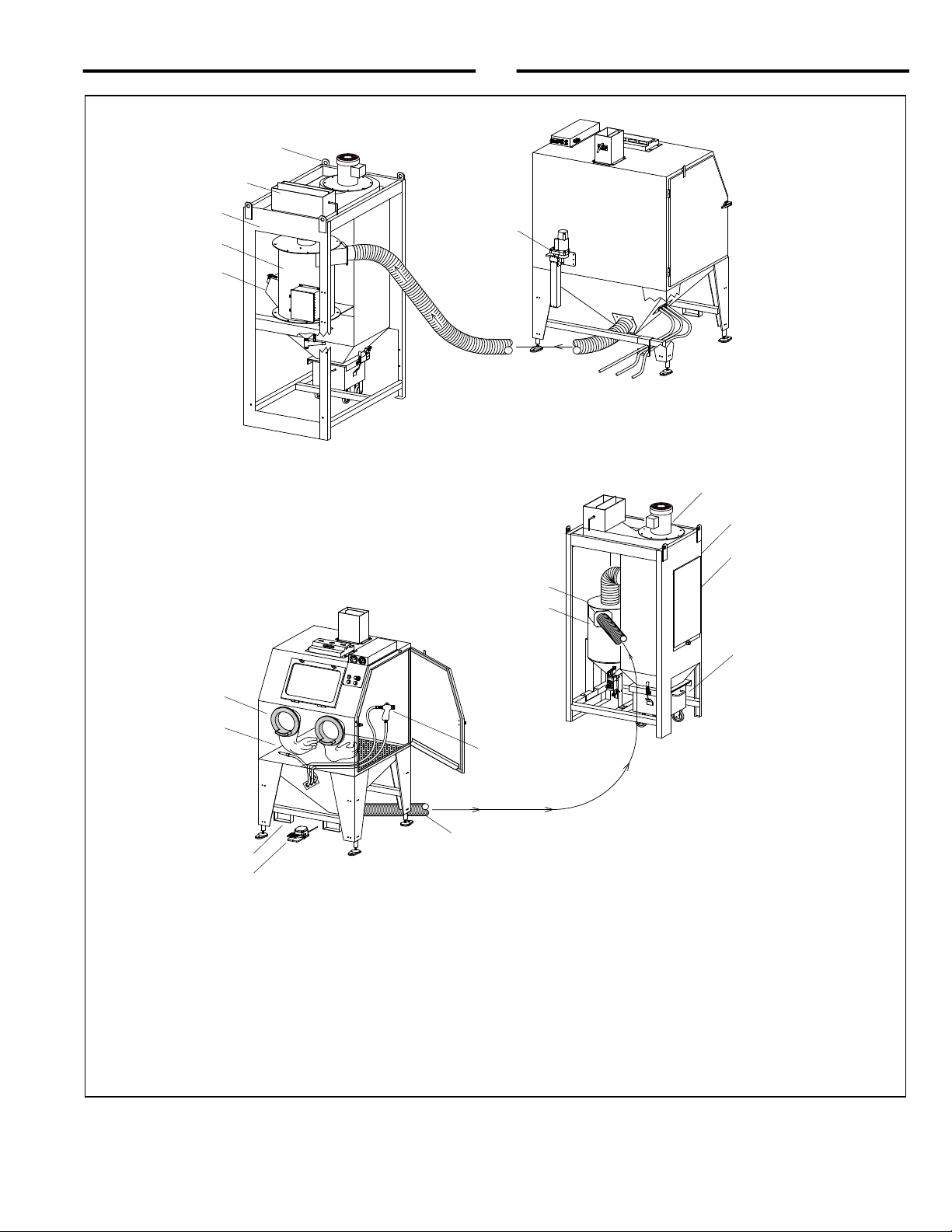

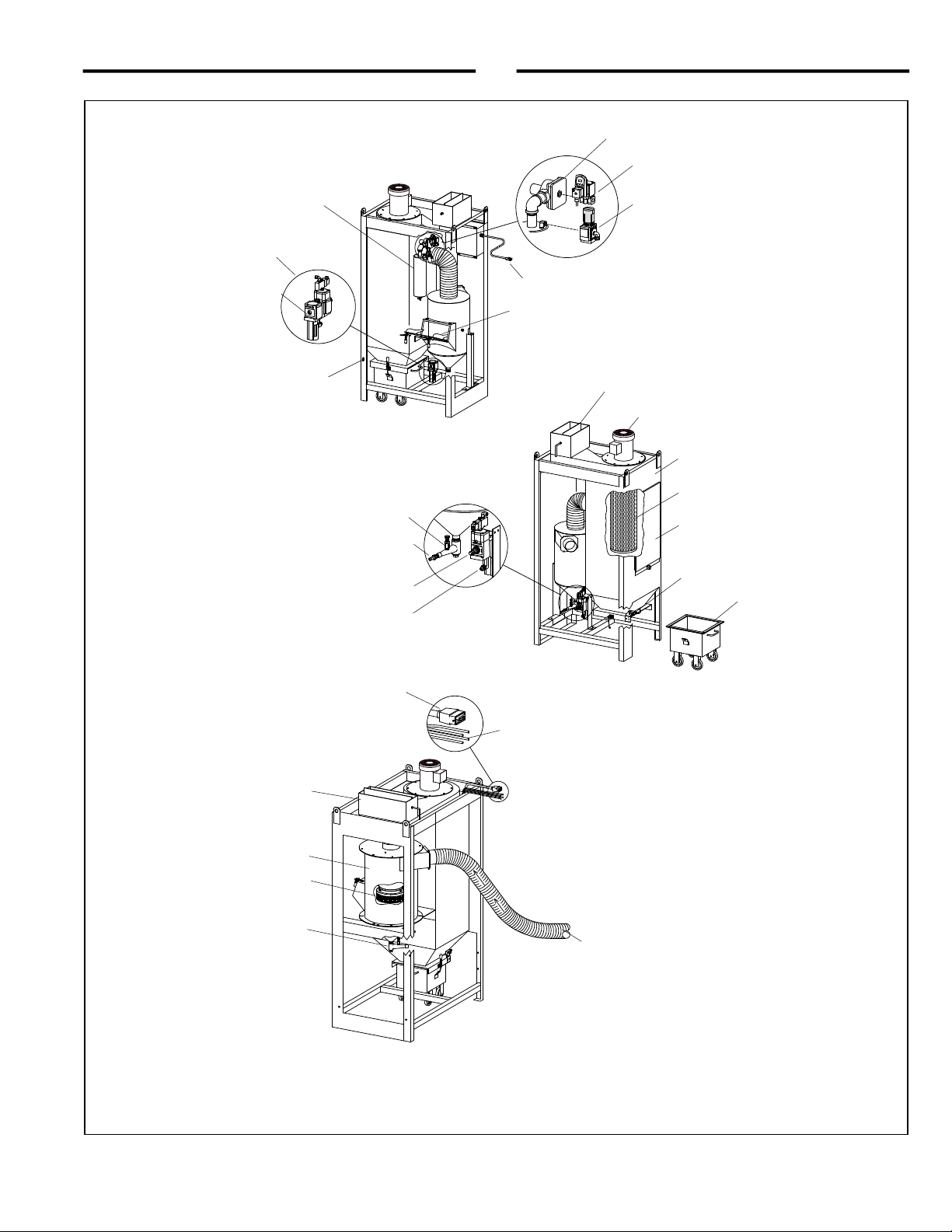

1.4 General Description

1.4.1 The Pulsar Plus cabinets encloses the blasting

environment to provide efficient blasting while maintaining a

clean surrounding work area. Production rates are

influenced by size of air jet and nozzle, compressor output,

working pressure, type and size of media, and angle and

distance of the nozzle from the blast surface. Pulsar Plus

Suction Cabinets consist of two major components.

1. Cabinet Enclosure

2. 300 cfm or 600 cfm Power Module

Refer to Figure 1 for arrangement and primary

components of the cabinet and power module.