INEX SUCTION BLAST CABINET with 300 CFM RECLAIMER Page 8

© 2005 CLEMCO INDUSTRIES CORP. •www.clemcoindustries.com •Manual No. 21803 Rev. D 03/05

5.0 PREVENTIVE MAINTENANCE

WARNING

Failure to wear approved respirators and eye

protection when servicing dust-laden areas of

the cabinet and dust collector, and when

emptying the dust bag or collector could result

in serious eye irritation and lung disease or

death. Toxicity and health risk vary with type of

media and dust generated by blasting. The

respirator must be approved for the type of dust

generated. Identify all material being removed

by blasting, and obtain a material safety data

sheet for the blast media.

NOTE: To avoid unscheduled downtime, establish a

weekly inspection schedule. Inspect all parts subjected

to media contact, including; the gun, nozzle, media hose,

flex hose, and wearplate, plus all items covered in this

section.

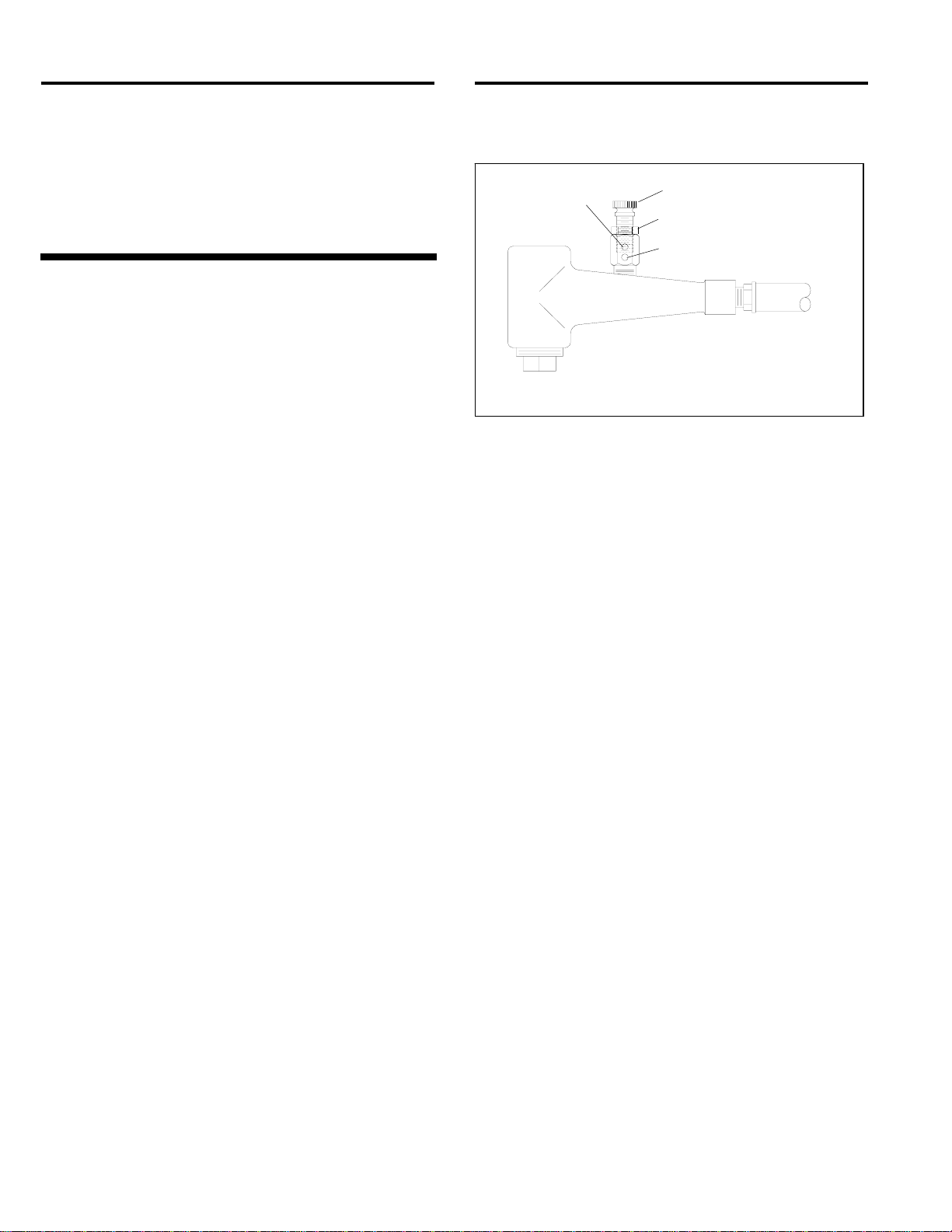

5.1. BNP Gun Assembly

5.1.1 Inspect the BNP gun for wear. Inspection and

replacement of the air jet cover before it wears through

will prolong the life of the jet.

5.2 Dust Bag

5.2.1 The bag collects dust on its inner surface. A high

dust level in the cabinet indicates a dirty bag. Empty as

frequently as necessary to maintain visibility in the

cabinet, and before the weight of dust prevents full

inflation of the bag. A zipper opening is located in the

bottom of the bag for emptying. NOTE: Poor visibility

and frequent emptying of the bag could indicate the

need to upgrade to a dry filter dust collector.

5.3 Dry Filter Dust Collector

5.3.1 The dry filter uses tubular filters, which collect

dust on their inner surfaces. A shaker arm accessible

from the outside of the collector is used to shake dust

from the filters. Every two hours, turn off the exhauster

and shake the filters vigorously.

CAUTION

Do not shake the filters when the exhauster is

on, doing so will accelerate wear on the filters

around the shaker assembly, but not shake the

dust loose.

5.3.2 Empty the dust collector drawer regularly. Begin

by checking the drawer daily and adjust frequency based

on usage and breakdown rate of media. Dump the

contents into a suitable disposal container.

CAUTION

Do not open the dust drawer door while the

exhauster is on. The drawer chamber is under

positive pressure when the exhauster is on.

Opening the dust door while the exhauster is

operating or the paddle wheel rotating, will

allow dust to escape.

NOTE: Blast media is usually non-toxic, however, some

materials removed by the process may be toxic. Do not

use the INEX cabinet for blasting toxic materials.

Use cabinets with reverse pulse dust collectors and

HEPA filters for those applications.

5.4 View Window Cover Lens

5.4.1 Rapid frosting of the view window can be

avoided by directing ricocheting media away from the

window, and by installing a cover lens on the inside

surface of the window. Using cover lenses prolongs the

life of the view window.

5.4.2 To install a cover lens, remove the adhesive

backing and apply the lens to the clean, dry, inner

surface of the view window. When the cover lens

becomes pitted or frosted, peel it off and replace it.

5.5 Reclaimer Debris Screen

5.5.1 The screen is accessible through the reclaimer

door. With the exhauster off, remove the screen and

empty it daily or when loading media. Empty the screen

more often if part blasted causes excessive debris. Do

not operate the machine without the screen in place.

5.6 Air Filter

5.6.1 The cabinet is equipped with a manual drain air

filter. Drain the filter at least once a day, and more often

if water is present. Moist air inhibits the flow of media. If

moisture continues to be a problem, a dryer or after

cooler may be required in the air supply line.

5.7 Media Hose

5.7.1 To avoid unscheduled down-time, periodically

inspect the media hose for thin spots, by pinching it

every 6 to 12 inches. Replace the hose when it becomes

soft.