Zest sources all of its timber from

responsibly-managed forests and

everything it designs and produces

meets the highest standards of

sustainability. Zest ensures that all

timber and timber-related products

are certied to Forestry Stewardship

Council (FSC®).

This is vital not only for the health

of the planet, but also shows Zest’s

commitment to the environment and

to responsible sourcing. Timber is a

natural material and, as such, will t

beautifully within any outdoor space.

This also means that all Zest pieces are

unique because every piece of timber

has its own distinctive features.

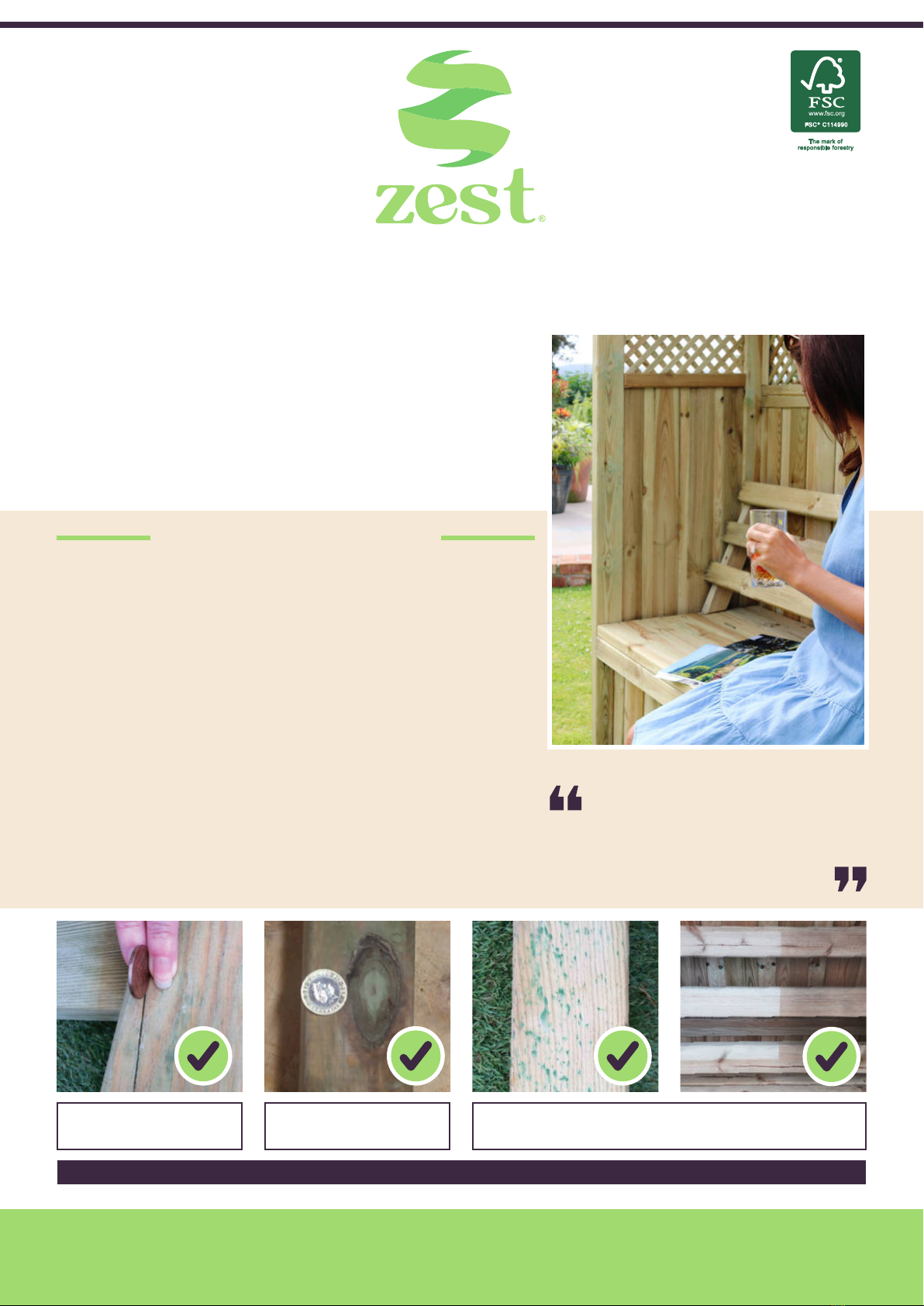

Every Zest product is unique because each piece of

timber has its own distinctive, natural features.

Normal splits are

characteristics of timber.

Knots are characteristics

of timber.

Sun Bleaching & Green Spotting are not causes for concern and they

will fade over time when items are placed outdoors.

Slow grown timber from Eastern

Europe is ideal for timber garden

furniture. It produces a stronger

grain in the wood giving it more

durability and is said to be as

strong as some hard woods.

The benets of slow grown timber

FURNITURE | ARBOURS | GROW YOUR OWN | PLANTERS | TRELLIS | FENCING & MORE...

WWW.ZESTOUTDOORLIVING.CO.UK

Natural and Unique...

Changes in temperature and humidity

will cause expansion and contraction

so Zest products need time to adjust to

where the owners live. A few splits or

cracks are part of the maturing process

and will not aect strength or durability.

Knots embedded in the wood are natural

and tell the story of the tree which made

them. Customers may notice variations

in colour but, once out in the garden and

exposed to the sun, colour and shading

will even out.

Most Zest products are pressure treated

which protects the timber from rot and

means customers will be able to enjoy the

products in their garden for many years.

Fresh pressure treatment sometimes

leads to a small amount of green-

spotting on the surface of new timber

as the natural salt leaves the wood.

This will fade away over time and is in no

way detrimental to quality or durability.

Splits and cracks occur naturally in

the timber grain due to changing

temperatures and humidity levels. They

are not usually a cause for concern

as they don’t aect the strength or

durability of the product. If however,

a 2p coin can t into the split or crack

there may be an issue so it should be

reported to the retailer in writing with

photographic evidence.

Should you find a large split or dead knot, please email a photo to your retailer for investigation.

00273