ZERO EMISSION VEHICLES AUSTRALIA 4-12 CELL LITHIUM BATTERY MANAGEMENT SYSTEM

long as necessary. Temperature limits may be adjusted in settings, to warn if the temperature

exceeds safe range, restrict charging if the battery is too cold, or shut everything down if the

battery gets too hot.

Sleep Mode

The BMS12i has a Sleep terminal which may be used to put the device into a lower power

standby mode by connecting a wire from it to a Ground terminal. It is most commonly

used in mobile applications, for when a vehicle is neither being driven or being charged.

(Stationary applications typically run 24/7 so the Sleep terminal is often unused.)

Sleep mode will shut down the CAN bus and turn off both relay outputs. The device continues

to monitor cell voltages and shunt current, and will turn itself off completely if any cells get

extremely low.

Automatic Pack balancing

In battery packs built from many cells, optimum performance is attained when all cells are at

the same State of Charge, also known as pack balance. The BMS12i uses a system known as

“shunt balancing”, which switches on resistors across any cells which are above a threshold

voltage to reduce their charge and bring them into line with other cells.

By default the BMS12i uses a dynamic balance threshold, where any cells more than 0.01V

above the average receive balancing. The threshold may also be set manually – if so it is

best to set it to the average maximum charge voltage, so that only cells above average at the

end of a charge receive balancing. Manually setting a shunt threshold below the maximum

charge voltage is not recommended since it may result in all balancers running concurrently,

which actually negates the effect and generates extra heat. Balancing can also be disabled.

The shunt balancers are quite small and can take a long time to correct large imbalances. If

possible it is recommended to manually balance your cells prior to initial pack assembly (e.g

by charging each cell individually, or wiring them all together in parallel to equalise with each

other). However the shunts will get an unbalanced pack incrementally closer to balanced each

charge, and once balanced are able to maintain balance with minimal effort.

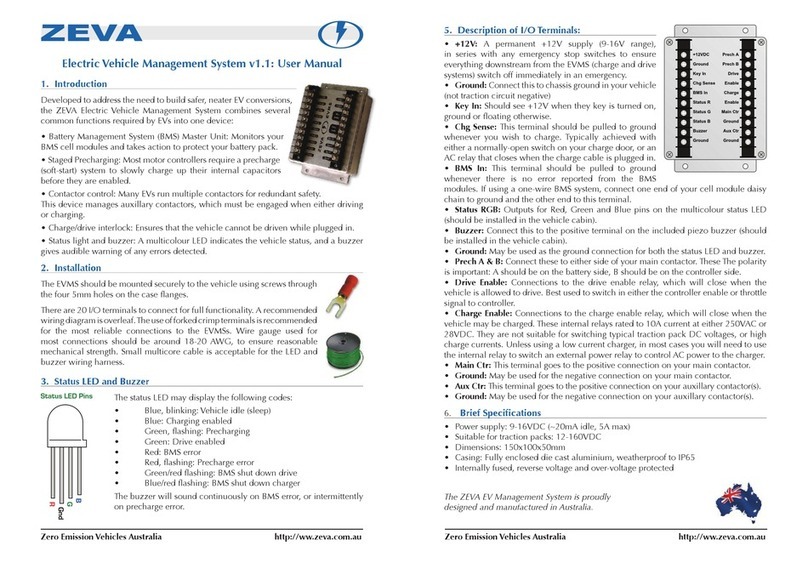

CAN Bus Wiring

The BMS12i has four screw terminals for connecting CAN bus

wiring: 6V Out, CAN H, CAN L and Ground. The monitor CAN

plug uses a Molex Eurostyle screw terminal. These connectors

require some force to plug in, so make sure the plug is fully

inserted for a reliable connection. Wiring for the Eurostyle

connector is shown right.

Wire gauge around 20-24AWG is recommended for appropriate current rating and

mechanical strength. For best noise immunity in high EMI environments, shielded twisted

pair cable is recommended, with two conductor pairs – one pair for CAN signals, and one pair

for bus power. The shield can be connected to the Ground terminal at the BMS. We use and

recommend Belden 8723 wire or equivalent.

For optimum performance, CAN buses should be wired as a single daisy chain of devices

(without branching), and terminated at both ends of the bus with a 120Ω resistor across the

CAN H and CAN L lines. The monitor includes termination resistor built-in. Note that the

CAN bus shares its ground reference with battery negative (it is not an isolated interface).

The 6V Out terminal is limited to 200mA current and is primarily intended for powering CAN

devices such as a monitor and/or CAN current sensor, but may also be used to power other

small 6V devices such as solid state relays.

BMS12i Monitor

The BMS12i Monitor is an optional colour touchscreen which may be used to remotely

interact with the BMS12i. The Monitor displays various pages of information:

BMS Status: Running

Voltage

Current

Power

Temp SoC

23˚C 90%

48.5V

12.3A

0.6kW

The BMS Status page is the standard display when

the system is running, showing pack voltage, current,

power, temperature, battery state of charge. This will

only be shown if a current sensor is present.

Tapping the panel on the left or right side will toggle

between the different display pages.

BMS Summary: 12 cells

Avg Volts Temperature

Min Volts Max Volts

3.32V 25˚C

3.31V 3.33V

The BMS Summary page shows the average, minimum

and maximum cell voltages, and the temperature

sensor, plus a bar graph overview of all cells across

the bottom.

If no current sensor is present, this will be the default

page, and Pack Voltage will be shown instead of

Average Voltage.

BMS Details: 12 cells

3.324 3.332 3.327 3.315

3.331 3.313 3.325 3.322

3.318 3.326 3.339 3.322

The BMS Details page shows all individual cell

voltages, plus a bar graph below. Dotted lines on the

graph show HV and LV thresholds plus hysteresis.

Graph bars will be green when a cell is in range, blue

for under-voltage, red for over-voltage, and orange if a

cell is currently being shunt balanced.

5 6

Shield

Ground

CAN L

CAN H

6VDC