16 modulmix

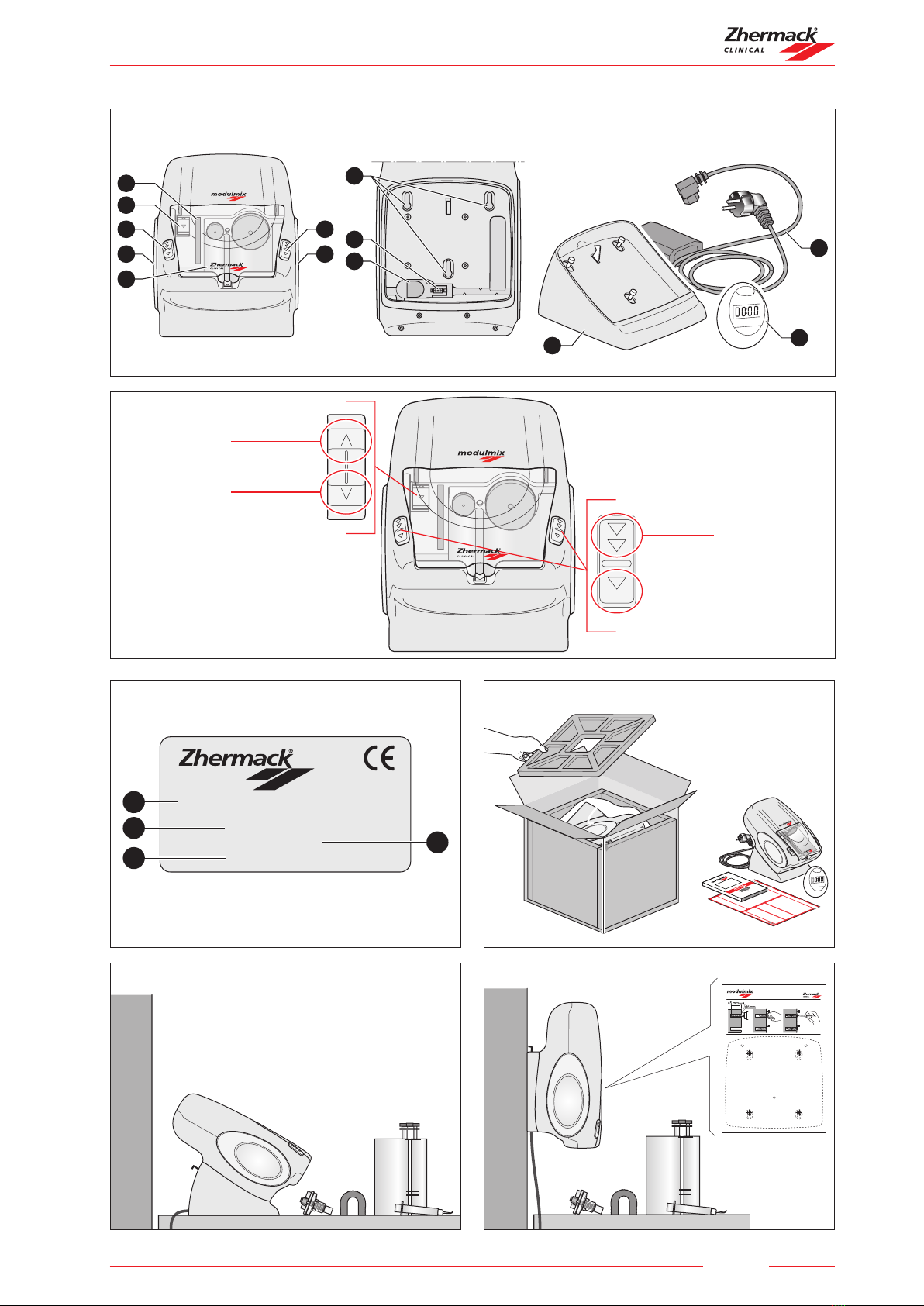

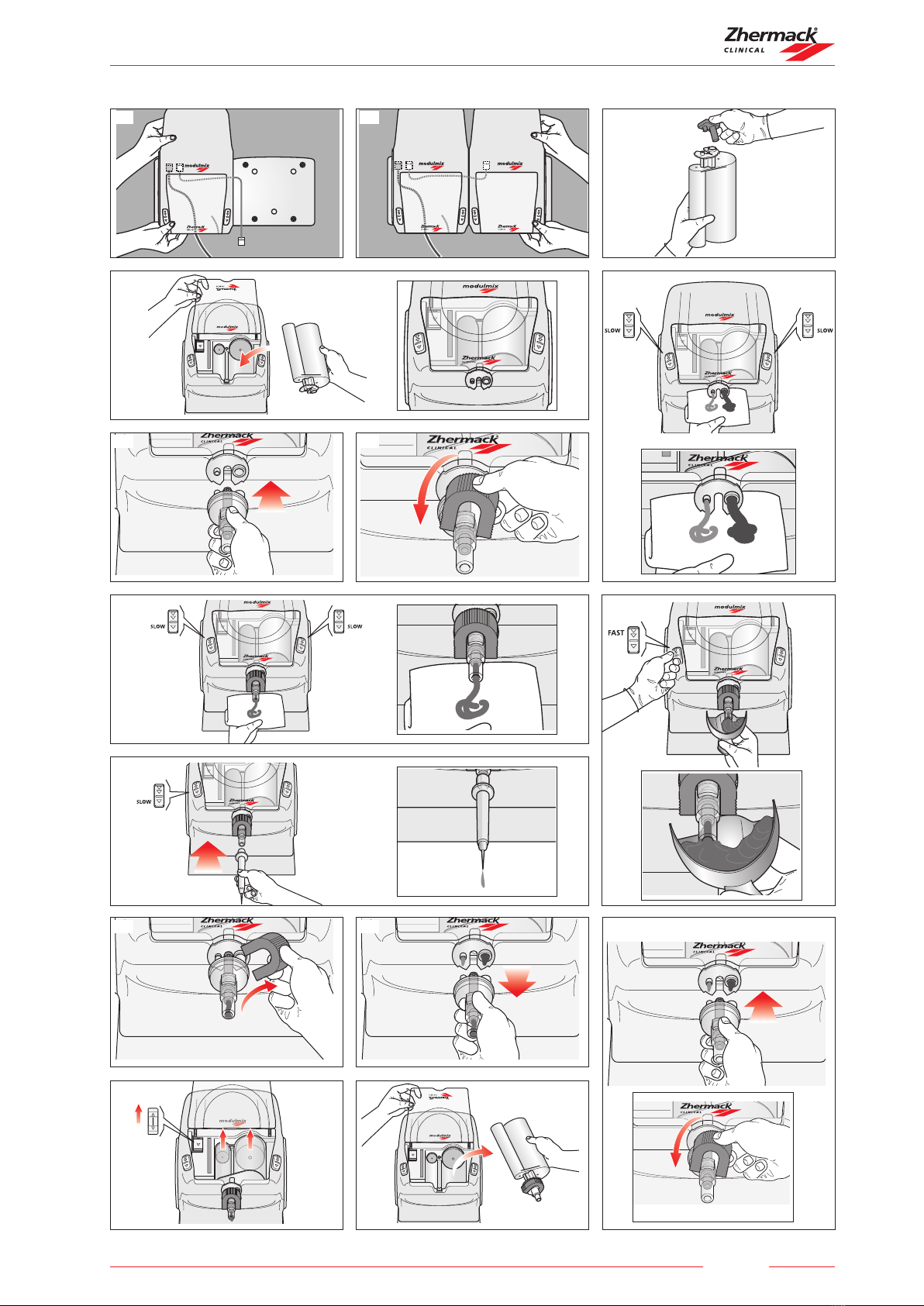

The reference figures are present on pages 3, 4 and 5 of this manual and in the product Quick Guide.

EN

• Any general information and/or useful advice referring to any

subject, will be highlighted with:

NOTE!

This symbol highlights information and/or useful advice.

CHAPTER 2: GENERAL INFORMATION

2.1 LIABILITY

Failure to comply with the instructions contained in this Use and

Maintenance Manual relieves the Manufacturer from any liability.

For any information not included or that cannot be deduced from

the Manual please contact the Manufacturer directly.

Zhermack S.p.A.

Via Bovazecchino, 100

45021 Badia Polesine - RO - Italy

Tel. +39 0425 597 611, Fax +39 0425 53 596

In particular, if machine maintenance is carried out in a way that

does not comply with the instructions provided or in a way to

jeopardise integrity or modify the features, Zhermack S.p.A. is

relieved from any liability inherent to safety of persons and faulty

operation of the machines.

2.2 WARRANTY: GENERAL STANDARDS

Find the Warranty Certificate and the Identification Form attached to

this Use and Maintenance Manual, which must be filled in completely.

Generally the warranty is rendered null and void by the following:

• improper use of the machine;

• incorrect installation;

• negligence of envisioned maintenance;

• modifications or interventions not authorised by the Manufacturer

(especially on safety devices);

• use of non-original spare parts.

IMPORTANT: Always keep the original product packaging

throughout the guarantee period. You will need the

packaging if the product has to be returned to the

Service Centre for repairs or replacement in the event of

manufacturing defects or malfunction (with the

exception of wilful damage, negligence, failure to

perform routine maintenance or damage during

transport). If you are not in possession of the original

packaging, contact Zhermack S.p.A. and ask for

instructions (possible repackaging costs will be charged

on delivery). The customer is responsible for all costs

associated with unsuitable packaging of the product to

be returned to the manufacturer. Zhermack is not liable

for faults, malfunctions or damage to the product

deriving from or consequent to the use of unsuitable

packaging, or packaging not of a quality equal to or

better than the packaging used for the original shipment.

As of this moment Zhermack S.p.A. is relieved from all

liability if any type of modification or tampering is made

on the machine without previous written authorisation

from the Manufacturer. Consequently, any repairs made

by unauthorised staff, use of non-original spare parts

or failure to comply with the installation standards

specified in this manual shall immediately render the

warranty null or void.

2.3 AUTHORISED STAFF

The staff in charge of the machine is divided into the following

categories:

Operator

Person trained to use the machine. He performs all tasks necessary

for operation, such as: running/activation of start/stop controls,

cleaning, inspection and simple interventions linked to normal

machine use.

Before using the machine or carrying out any

intervention on it, the operator must read the entire

manual carefully. This manual has been drawn up to

provide the user with essential information on rational,

safe use of the machine. The user must comply with the

information given at all times. The user must also use the

worksheets, attached to this manual, to keep a record

of maintenance interventions, component replacement

as well as make notes regarding anomalous functioning.

CHAPTER 1: INTRODUCTION

1.1 HOW TO READ AND USE THE USE AND MAINTENANCE

MANUAL

This “Use and Maintenance Manual” provides information

regarding the installation, use and maintenance of the modulmix

mixer, manufactured by Zhermack S.p.A.

• The machine must be used in compliance with that specified

in this Manual: it is therefore recommended that the manual

is read carefully prior to installation and start-up. Make sure

that you read the entire manual and pay particular attention to

messages written in bold type or items highlighted by boxes and/

or symbols, which highlight dangerous situations or requiring

caution (see paragraph 1.2).

• The respect of standards and recommendations shown in this

Manual will ensure safe use of the machine and appropriate

interventions on the same.

• The Use and Maintenance Manual is an integral part of the

machine: it should therefore be kept together with the machine

so that it can be consulted as and when necessary (in a secure dry

place away from sunlight, atmospheric agents, etc.) throughout

the working life of the machine, even when the machine is sold

or finally dismantled.

• It is advised to keep the Manual constantly updated, integrating

any amendments, additions or modifications made by the

Manufacturer. Any notes or comments should be made on the

blank pages at the rear of the Manual (see Attachments: Notes).

• Use the Manual in a way that its content is not damaged.

• Do not remove, tear or write on the Manual for any reason.

• If the Manual is lost or damaged and therefore becomes illegible,

request a new Manual from the Manufacturer.

This Use and Maintenance Manual is aimed at operators in order

to allow correct use of the product. The Manual contains all useful

information for declared used of the machine; in particular the

operator will find instructions and indications regarding:

• correct installation of the machine;

• a functional description of the machine and all parts;

• commissioning;

• correct programmed maintenance;

• attention to the most elementary safety and accident-prevention

regulations.

This Manual is divided into 9 chapters, each referring to a specific

subject inherent to the entire machine.

The attachments are found at the rear of the manual. They

complete the documentation.

1.2 TERMS AND SYMBOLS USED

It is fundamental that maximum attention is paid to the

following symbols and their meaning because they highlight

important information such as, critical situations, practical advice

or straightforward information. Consult this page if in doubt

regarding the meaning of the symbol when reading the Manual.

• Any operations carried out without compliance to instructions or

tampering with machine parts, which can cause serious injury to

persons, will be highlighted with:

DANGER!

This symbol refers to Safety Standards that MUST be

followed in order to guarantee your safety and that of

others and to prevent damage to the machine.

• Critical situations concerning dangerous areas, situations or

operations in which failure to comply with the instructions may

render the warranty null and void, cause damage to machine,

connected components or the surrounding area, are highlighted

by the symbol:

ATTENTION!

This symbol refers to Safety Standards that must be

followed carefully in order to guarantee your safety and

that of others and to prevent damage to the machine.

• Any operations carried out without compliance to instructions

or tampering with machine parts, which can cause damage

to the machine rendering the warranty null and void, will be

highlighted with:

PROHIBITED!

This symbol calls attention to operations that are

prohibited.