2

Zikodrive Motor Controllers are a product of Round Bank Engineering Ltd

Floor 2, Clifton Warehouse, Sowerby Bridge, West Yorkshire, HX6 2BY enquiries@Zikodrive.com –

www.zikodrive.com - +44 (0) 1422647177

Contents

Introduction....................................................................................................................................................... 4

Specification ...................................................................................................................................................... 4

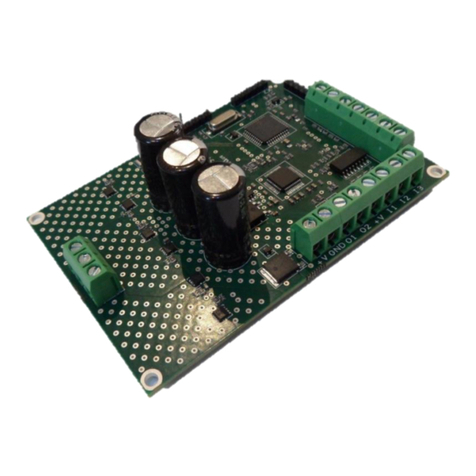

Connections on the ZDSMUL2-24...................................................................................................................... 5

Wiring Motor Phase Wires ................................................................................................................................ 6

Connecting the Power....................................................................................................................................... 6

Setting up the ZDA010 Controller Host programme......................................................................................... 7

Things you will need...................................................................................................................................... 7

Getting started .............................................................................................................................................. 7

Using the ZDA010 software to set parameters............................................................................................... 10

Key Values........................................................................................................................................................ 11

Step Size....................................................................................................................................................... 11

Interpolate................................................................................................................................................... 11

Enable Input................................................................................................................................................. 12

Connecting the enable input ................................................................................................................... 12

Direction Input............................................................................................................................................. 12

Connecting the direction input................................................................................................................ 12

Current Setting ........................................................................................................................................ 13

Holding Current ....................................................................................................................................... 14

Set RPM ................................................................................................................................................... 14

Acceleration & Deceleration Scalar............................................................................................................. 14

Voltage Minimum........................................................................................................................................ 15

Read Speed.................................................................................................................................................. 15

Fault............................................................................................................................................................. 15

Analogue RPM Limit .................................................................................................................................... 15

Output ......................................................................................................................................................... 16

Other Inputs/Outputs...................................................................................................................................... 17

Analogue Speed Input ..................................................................................................................................... 18

UART................................................................................................................................................................ 18

Troubleshooting .............................................................................................................................................. 19

Revisions.......................................................................................................................................................... 20

A:.............................................................................................................................................................. 20