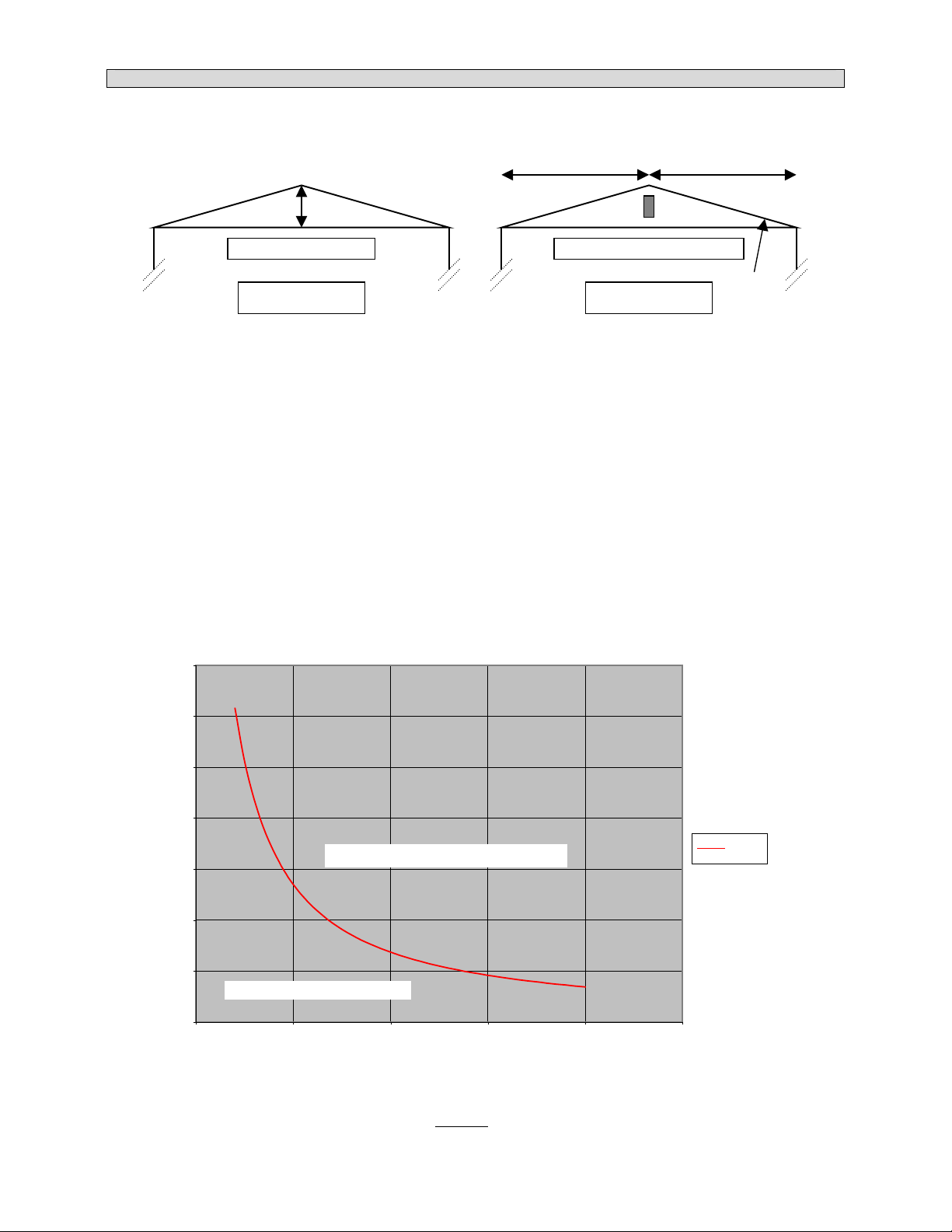

3.2. Detector Positioning In Atrium.

If the detector is to be placed in an atrium, or near glass/polished surfaces, the prism(s) should be offset from

the central line of sight (approximately 300mm), and angled back to the beam detector. This can be either on

the vertical or horizontal axis. This will reduce the amount of spurious returned signal from the glass/polished

surfaces. The reflected signal from the prism(s) will be returned to the detector in the normal way.

4. Installation.

Pre-installation at Ground Level.

Confirm that all parts have been supplied as listed in the parts list. See page 10.

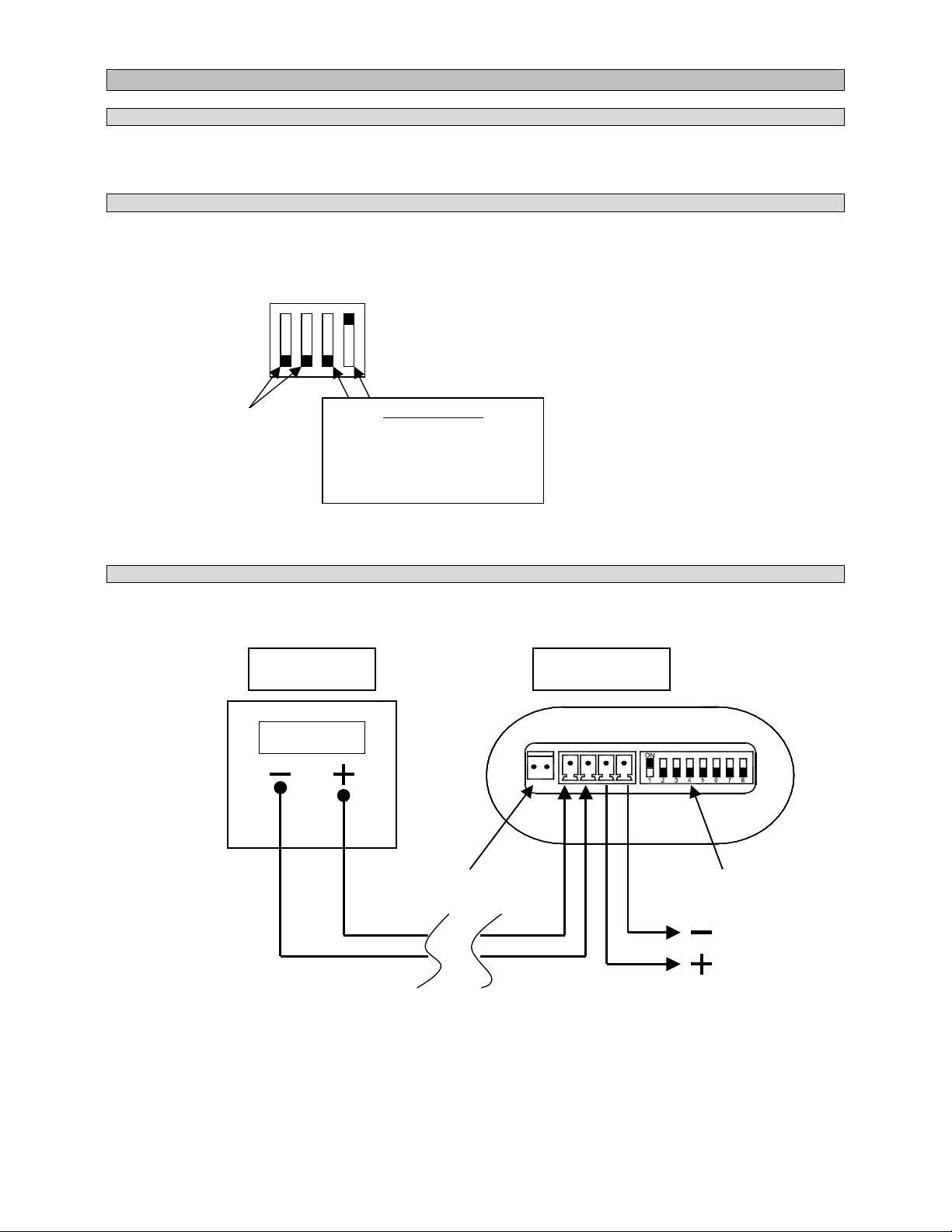

Select the required alarm threshold using configuration switches 3 and 4 (See page 8, fig. 4. for switch

configuration settings). The factory default setting is 35% this should be adequate for most environments, if the

Detector is to be installed into an exceptionally dirty environment change the threshold to 50%.

Select the required address using address switches 1 to 7 (See page 9, Table 1. for address switch settings)

where 1 is ‘ON’ and 0 is ‘OFF’. The factory default setting is address 1.

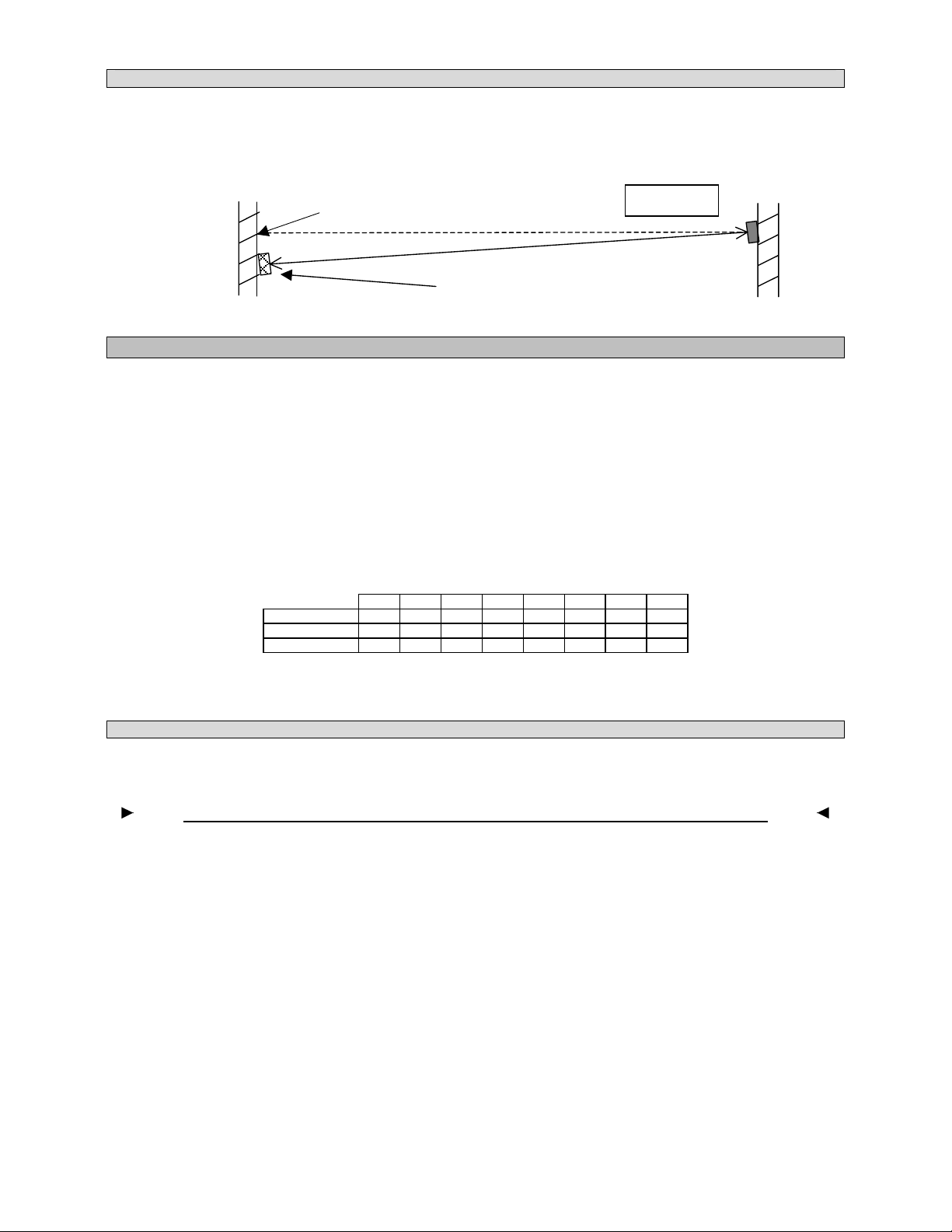

Shown below is an example of address 85 (1+4+16+64 = 85).

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

Switch Value 1 2 4 8 16 32 64 X

Switch Position ON OFF ON OFF ON OFF ON X

Logic 1 0 1 0 1 0 1 X

The Detector Head Assembly is now ready for installation. If configuration switches 3 and 4 require resetting

after installation, a power down reset is required (entering into Alignment Mode can also be used as a reset).

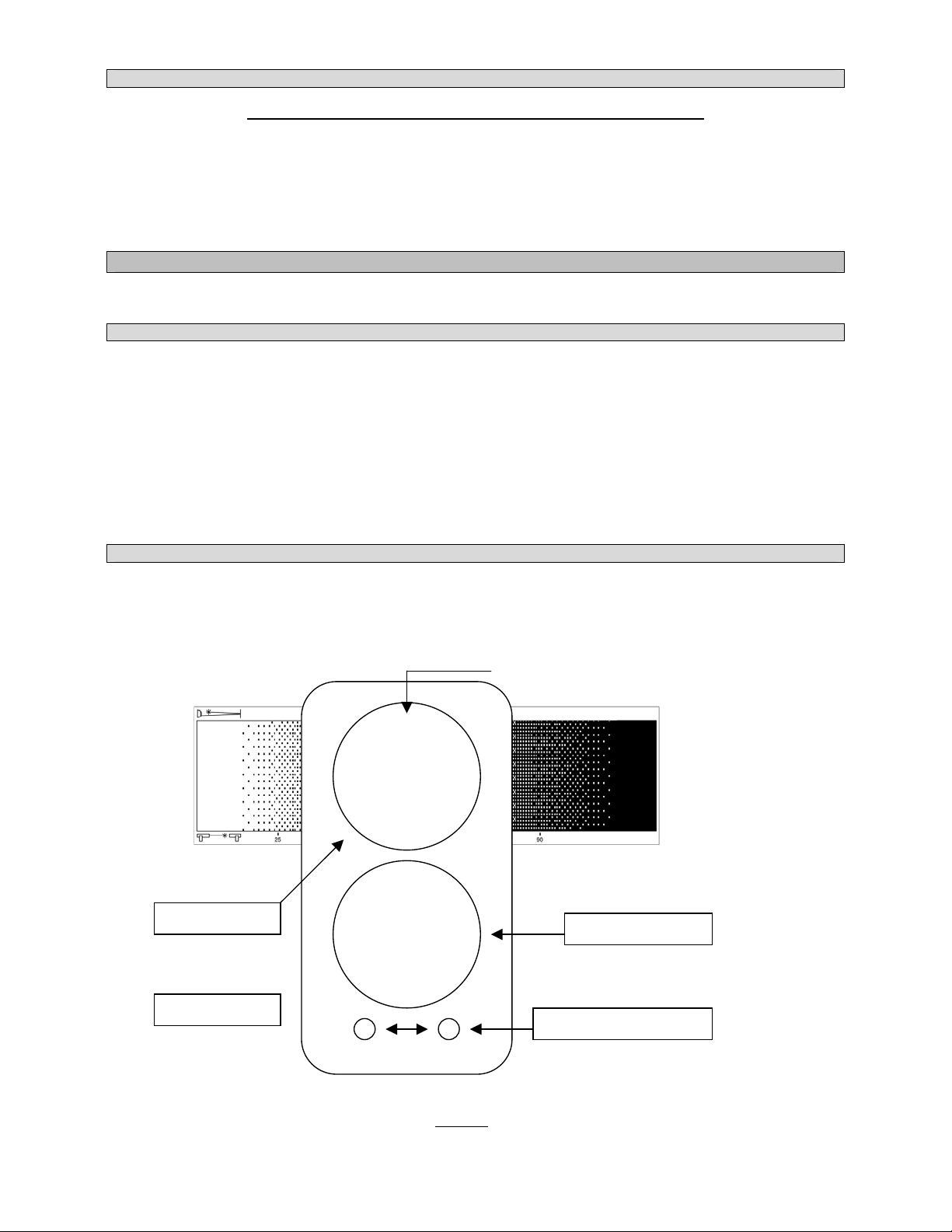

4.1. Detector Head Assembly Installation.

Remove the outer cover before installation; this is only to prevent the cover becoming dislodged during

handling.

Do not mount on plasterboard or cladded walls as these surfaces do, and will move.

Determine the position of the Head Assembly, which must be mounted on a solid structure between 0.5 and

0.6 metres below the ceiling, and no closer than 0.5 metres to an adjacent wall or structure. Ensure that there is

a clear line of sight to the proposed position of the prism(s), which is to be mounted on a solid structure

between 5 and 100 metres directly opposite the Detector (range dependent on model).

Using the template provided mark and install all 4 fixing points to the structure. The rear mounting plate of the

Detector Head Assembly is provided with 4 keyhole slotted apertures to allow for easy installation onto the 4

fixing points. Install the detector on the four mounting points.

Replace the outer cover.

Terminate the field wiring. See section 8.

Offset Prism(s) position and beam path

Normal Prism(s) position and

central line of sight Detector

head

Plan View

www.acornfiresecurity.com

www.acornfiresecurity.com