Automatic Barrier Gate Instructions

contents

Chapter 1 Overview................................................................................................................................................ 2

1.1 Appearance and Dimensions of the Chassis....................................................................................... 2

1.2 Appearance and Dimensions of the Boom of the Barrier Gate......................................................... 2

1.3 Chassis Components .................................................................................................................................... 4

1.4 Working Principles.................................................................................................................................... 4

1.5 Specification Parameters of Product Series ................................................................................................. 6

Chapter 2 Product Installation............................................................................................................................... 7

2.1 Installation Precautions ........................................................................................................................... 7

2.2 Cable Embedding..................................................................................................................................... 7

2.2.1 Cable Embedding Procedure...................................................................................................... 7

2.2.2 Cable Specifications..................................................................................................................... 7

2.3 Civil Installation of the Chassis............................................................................................................... 8

2.4 Boom Installation...................................................................................................................................... 9

2.5 System Diagram..................................................................................................................................... 11

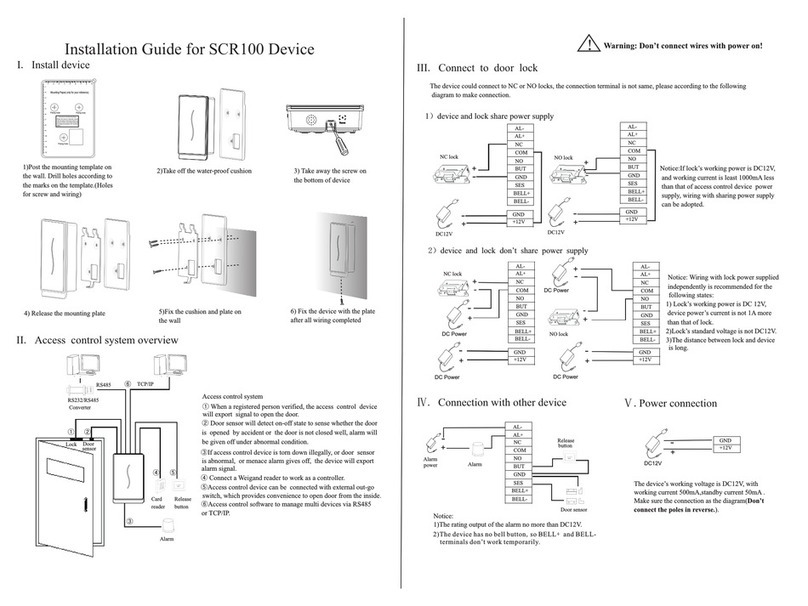

Chapter 3 Device Wiring and Commissioning.................................................................................................. 13

3.1 Commissioning Preparations................................................................................................................ 13

3.2 Commissioning Procedure.................................................................................................................... 13

3.3 Additional Functions (Optional)................................................................................................................. 14

Chapter 4 Common FAQs................................................................................................................................... 15

Chapter 5 Device Maintenance.......................................................................................................................... 16

5.1 Maintenance Items................................................................................................................................. 16

5.2 Maintenance Period............................................................................................................................... 16

Appendix 1 Packaging List.................................................................................................................................. 17

Appendix 2 Wiring Diagram of the Control Board............................................................................................ 18