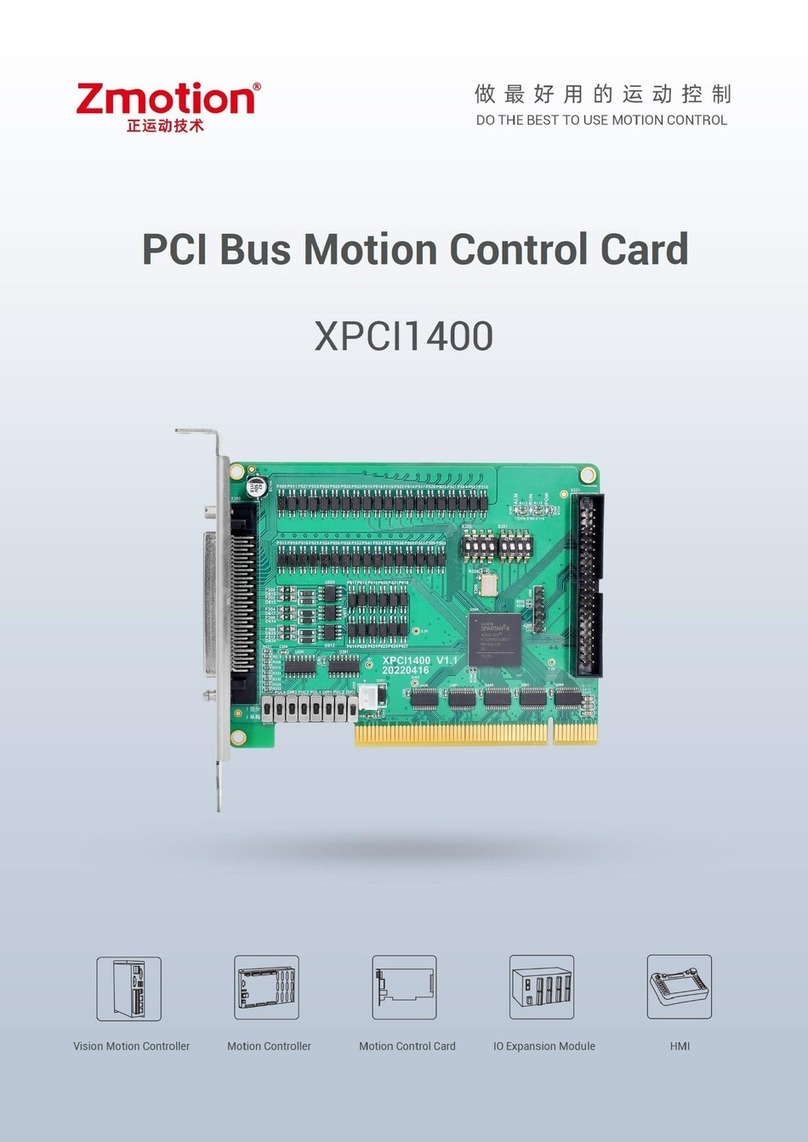

XPCI1C00 Motion Control Card User Manual V1.0

Content

Chapter I Production Information........................................................................................3

1.1. Product Information ..........................................................................................3

1.2. Function Features..............................................................................................3

1.3. System Frame ...................................................................................................4

1.4. Model Information.............................................................................................4

1.5. Hardware Installment........................................................................................5

Chapter II Product Specification .........................................................................................7

2.1. Basic Specification............................................................................................7

2.2. Interface Definition............................................................................................7

2.3. Work Environment .............................................................................................8

Chapter III Wiring, Communication Configuration ..............................................................9

3.1. Power Input .......................................................................................................9

3.2. X300, X301 Signal Interface..............................................................................9

3.2.1. ACC-1C00 Adapter .................................................................................9

3.2.2. Terminal Definition ...............................................................................10

3.3. X500 Signal Interface......................................................................................16

3.3.1. Adapter EXDB37M-37 ..........................................................................16

3.3.2. Terminal Definition ...............................................................................17

3.4. Pulse Directional Output .................................................................................17

3.4.1. Pulse Direction Axis Specification & Wiring.........................................18

3.4.2. Basic Usage Method ............................................................................19

3.5. Encoder Input ..................................................................................................21

3.5.1. Encoder Interface Specification & Wiring.............................................21

3.5.2. Basic Usage Method ............................................................................22

3.6. IN: Digital Input................................................................................................24

3.6.1. Digital Input Specification & Wiring .....................................................24

3.6.2. Position Sensor & Signal Distribution..................................................27

3.6.3. Basic Usage Method ............................................................................27

3.7. OUT: Digital Output..........................................................................................28

3.7.1. Digital Output Specification & Wiring...................................................28

3.7.2. Basic Usage Method ............................................................................29

3.8. DIP Switch .......................................................................................................30

3.8.1. Differential/Single-ended DIP Switch ..................................................30

3.8.2. S200 DIP Switch...................................................................................31

Chapter IV Accessories .....................................................................................................32

4.1. Standard Accessories .....................................................................................32

4.2. Optional Accessories ......................................................................................33

Chapter V Installation........................................................................................................35