2

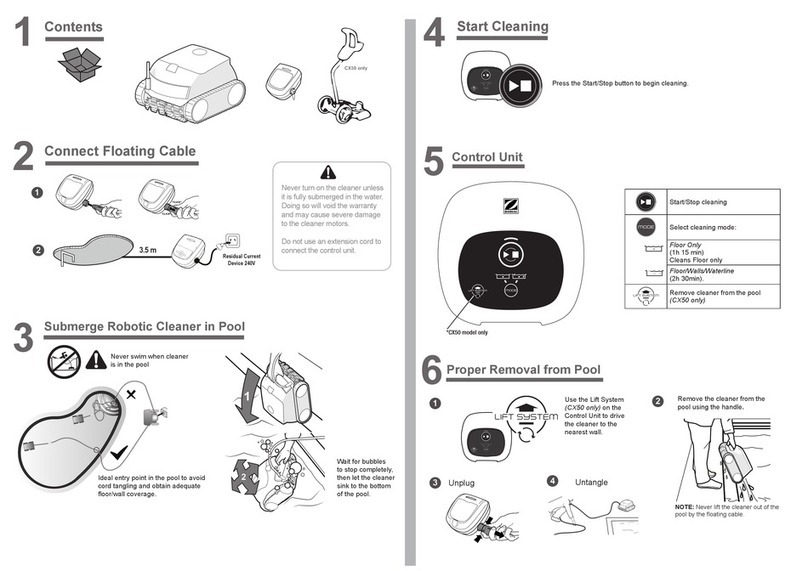

CONTENT

1. TROUBLESHOOTING............................................................................................................................................... 3

1.1. THE INDIGO DOESN'T MOVE OR SUCK UP ANY LITTER.............................................................................................. 3

1.2. WALL CLIMBING .................................................................................................................................................... 3

1.3. ROBOT TILTS BACKWARD ...................................................................................................................................... 4

1.4. ROBOT EMERGING ABOVE THE WATER LINE............................................................................................................ 4

1.5. BAD ADHESION TO POOL BOTTOM ......................................................................................................................... 5

1.6. NO MOVEMENT –SUCTION OK ............................................................................................................................... 5

1.7. FILTRATION INEFFECTIVE....................................................................................................................................... 6

2. ASSEMBLY / DISASSEMBLY .................................................................................................................................. 7

2.1. TOOLS REQUIRED ................................................................................................................................................... 7

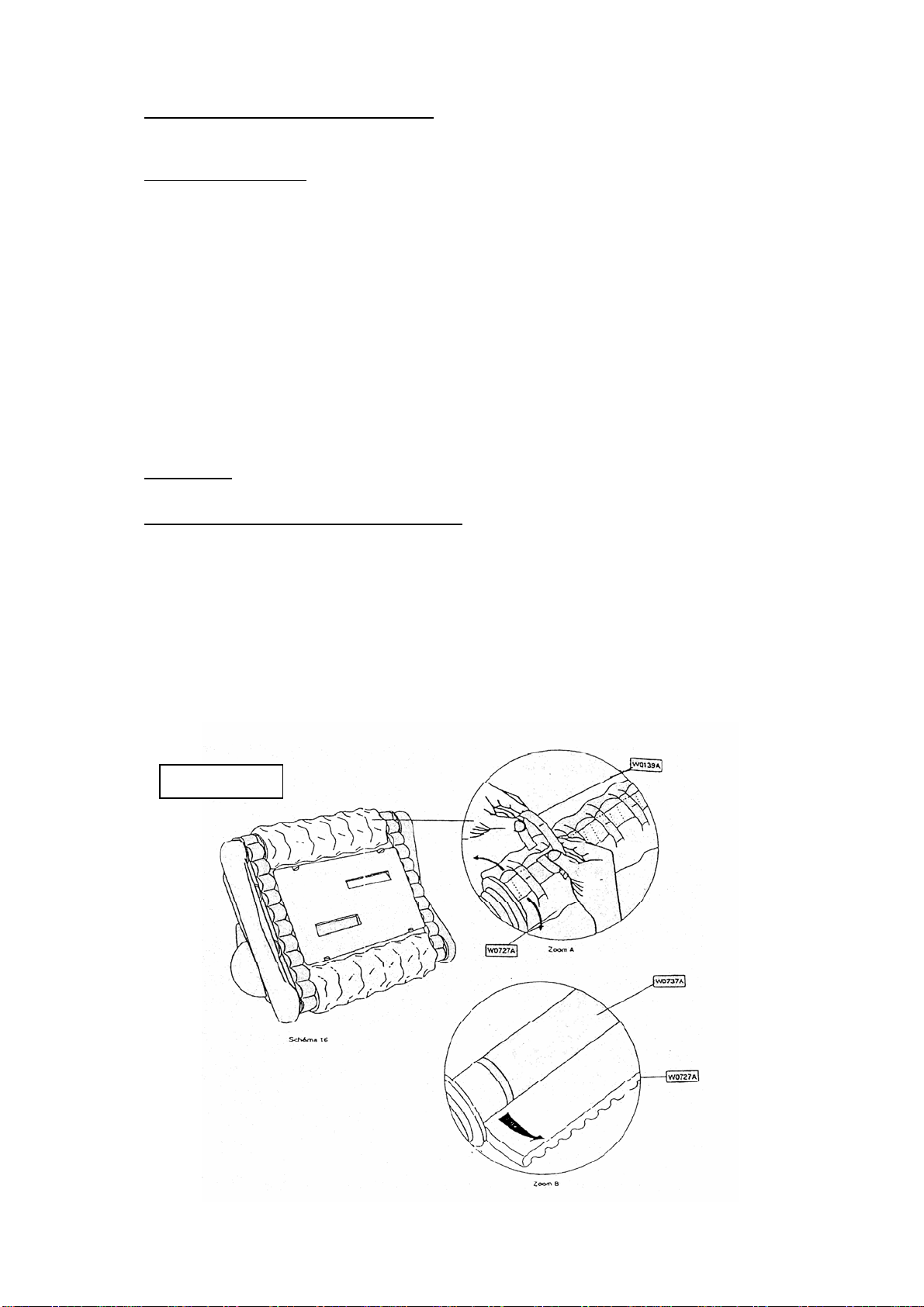

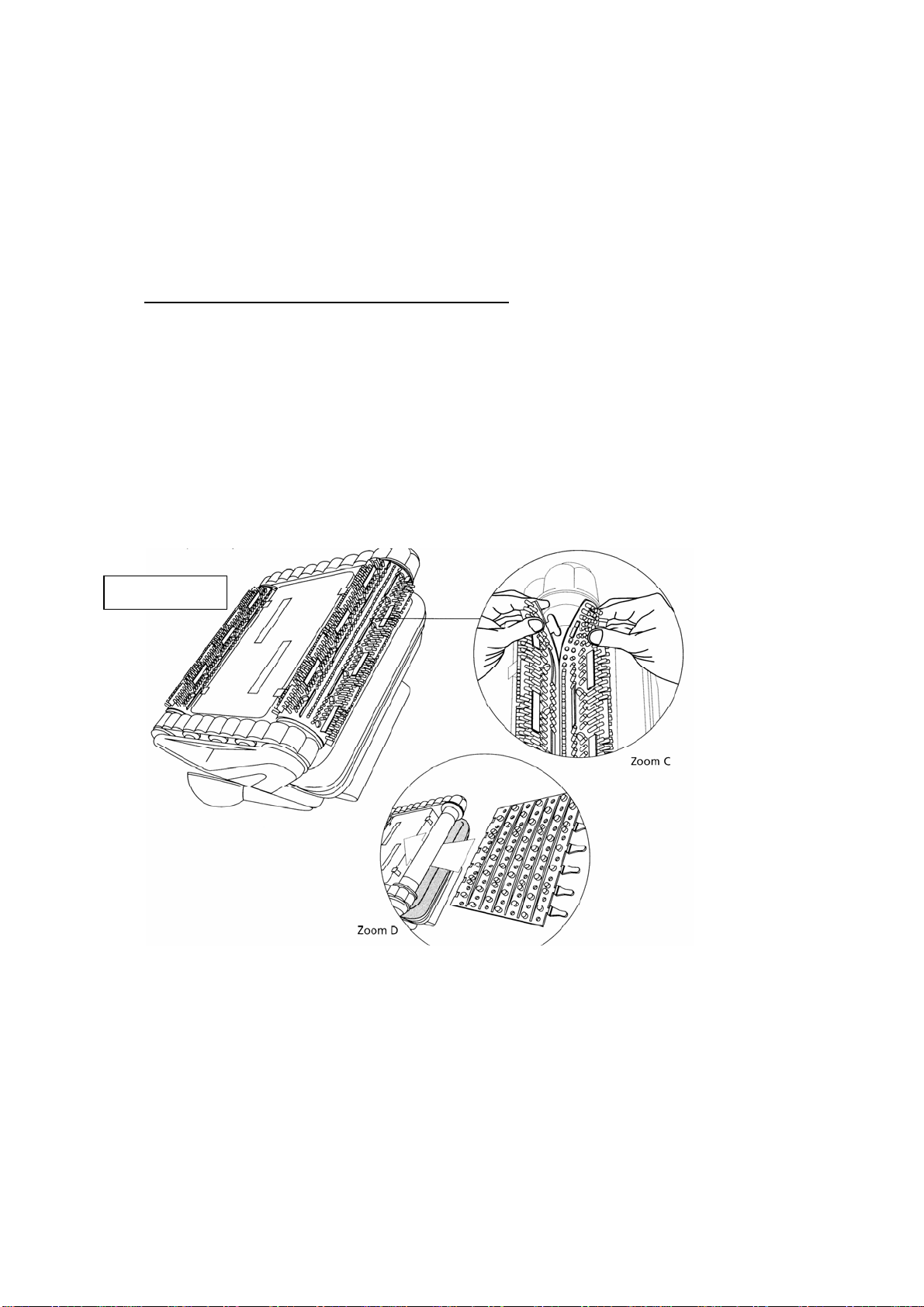

2.2. BRUSHES ................................................................................................................................................................ 7

2.2.1. Your robot is fitted with foam pads............................................................................................................... 7

2.2.2. Your robot is fitted with rubber brushes....................................................................................................... 8

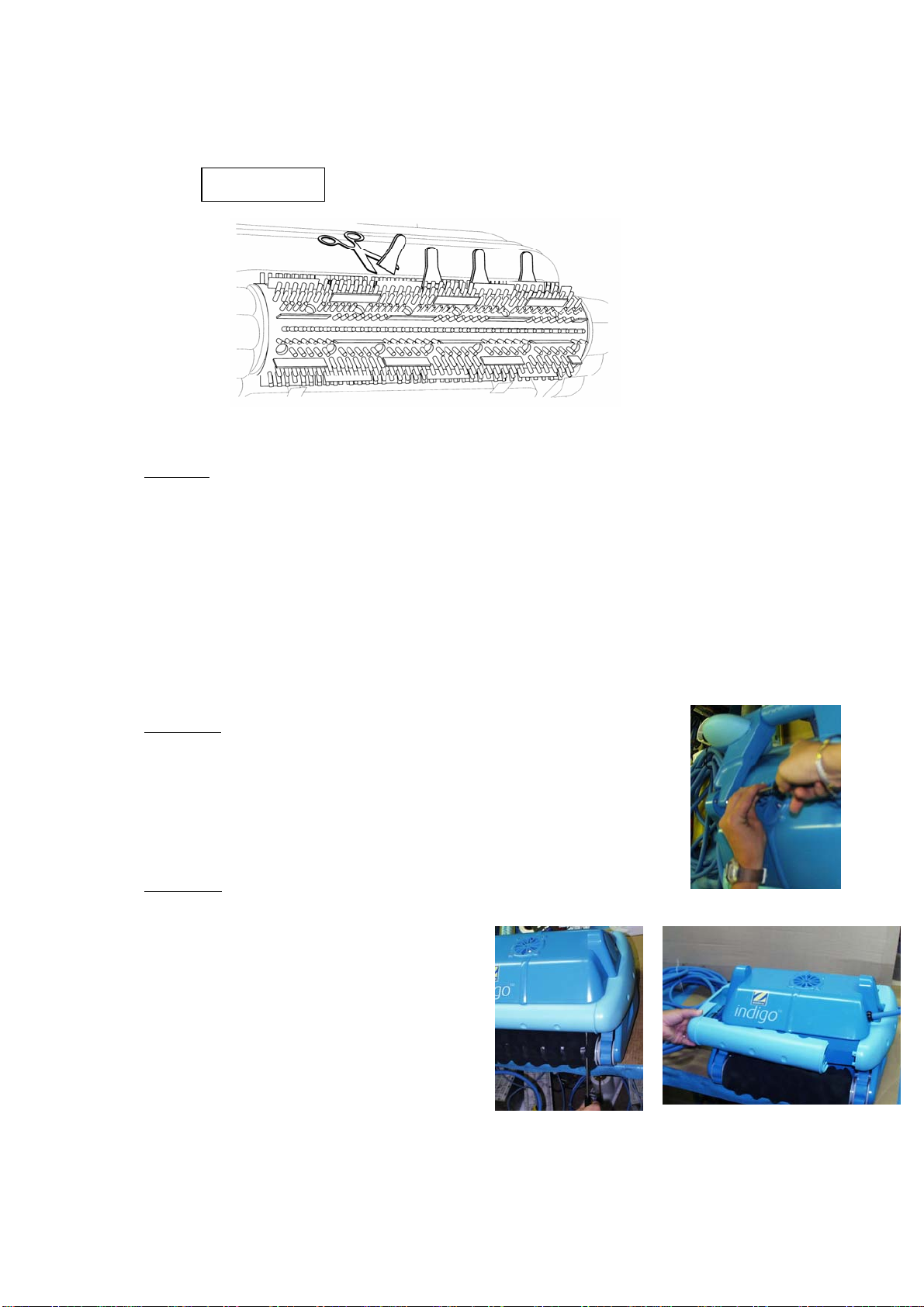

2.3. ROTOR.................................................................................................................................................................... 9

2.4. HANDLE.................................................................................................................................................................. 9

2.5. BUMPER.................................................................................................................................................................. 9

2.6. MOTOR UNIT PROTECTIVE SCREEN ...................................................................................................................... 10

2.7. TRACK PLATE ON TRACTION SIDE (SIDE OPPOSITE CABLE)................................................................................... 10

2.7.1. Removal of the Track Plate......................................................................................................................... 10

2.7.2. Track........................................................................................................................................................... 11

2.7.3. Drive Roller – Transmission Belt – Track .................................................................................................. 11

2.7.4. Track Plate.................................................................................................................................................. 12

2.7.5. Belt Tension Jacks....................................................................................................................................... 12

2.7.6. Belt Settings................................................................................................................................................. 12

2.7.7. Fitting the Traction Track Plate (side opposite cable) ............................................................................... 12

2.8. CABLE SIDE TRACK PLATE................................................................................................................................... 13

2.8.1. Removing the Cable-Side Track Plate ........................................................................................................ 13

2.8.2. Track Guide Roller Track ........................................................................................................................... 14

2.8.3. Track Plate.................................................................................................................................................. 14

2.8.4. Plate Assembly (cable side) on the Housing............................................................................................... 14

2.9. MOTOR UNIT ........................................................................................................................................................ 14

2.9.1. Removing the Motor Unit............................................................................................................................ 15

2.9.2. Replacing the Motor Unit ........................................................................................................................... 15

3. TECHNICAL DIAGRAMS....................................................................................................................................... 17

3.1. GENERAL DIAGRAM ............................................................................................................................................. 17

3.2. TROLLEY (W1210A)............................................................................................................................................ 18

3.3. MOTOR UNIT (W1287A)....................................................................................................................................... 19

3.4. CONTROL UNIT (W1207A) ................................................................................................................................... 21

3.5. HOUSING (W1286A) ............................................................................................................................................ 22

3.6. MOTOR HOUSING COVER (W0684A) .................................................................................................................... 23

3.7. FLEXIBLE LEAD KIT (W1313A) ............................................................................................................................ 24

3.8. PUMP MOTOR (W1290A)...................................................................................................................................... 25

3.9. GEARED TRACTION MOTOR (W1166A)................................................................................................................. 26

3.10. FILTER HOLDER (W1201A) .................................................................................................................................. 27

4. PARTS LIST............................................................................................................................................................... 28

5. CONTACT INDIGO TECHNICAL DEPARTMENT........................................................................................... 30