2

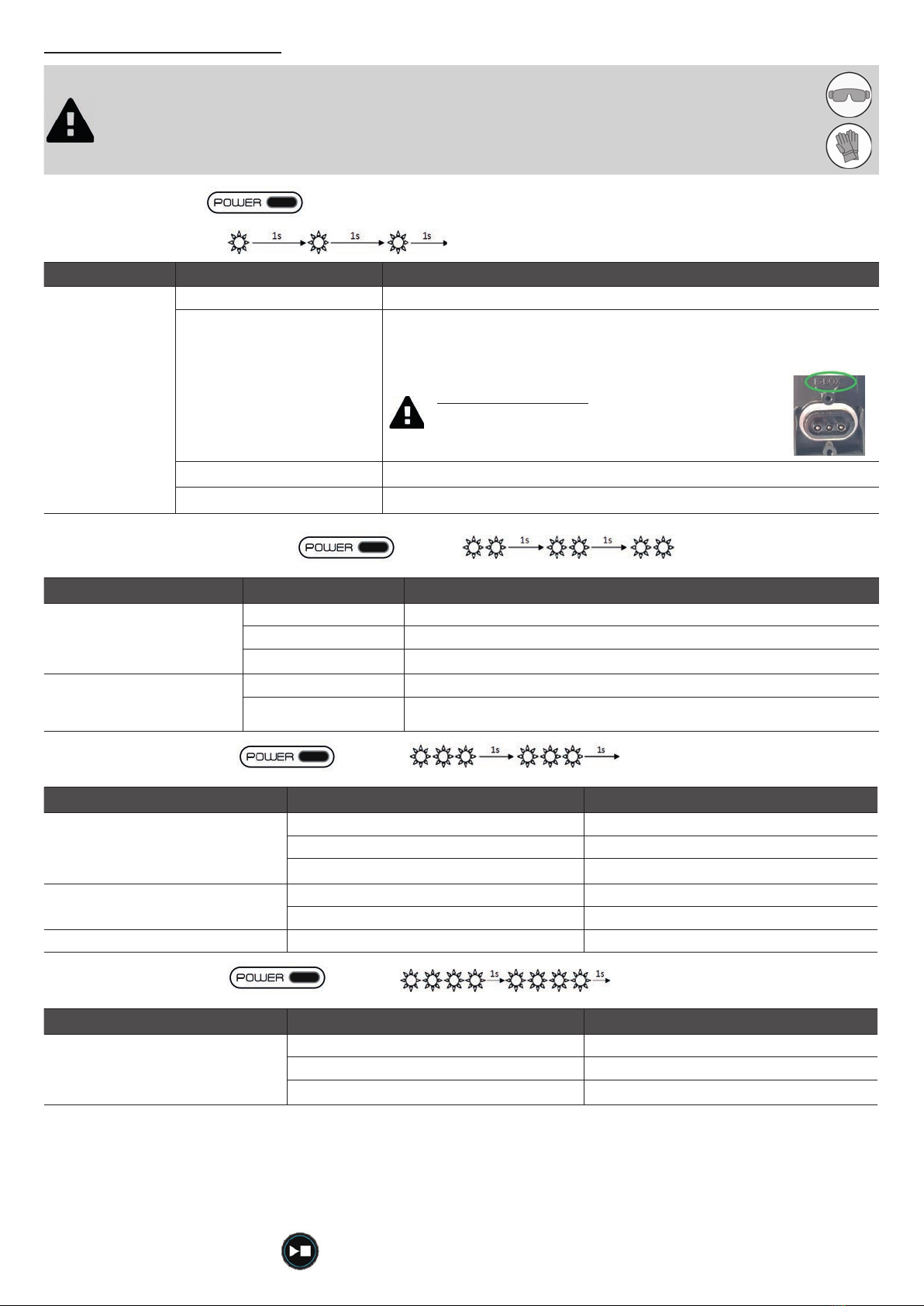

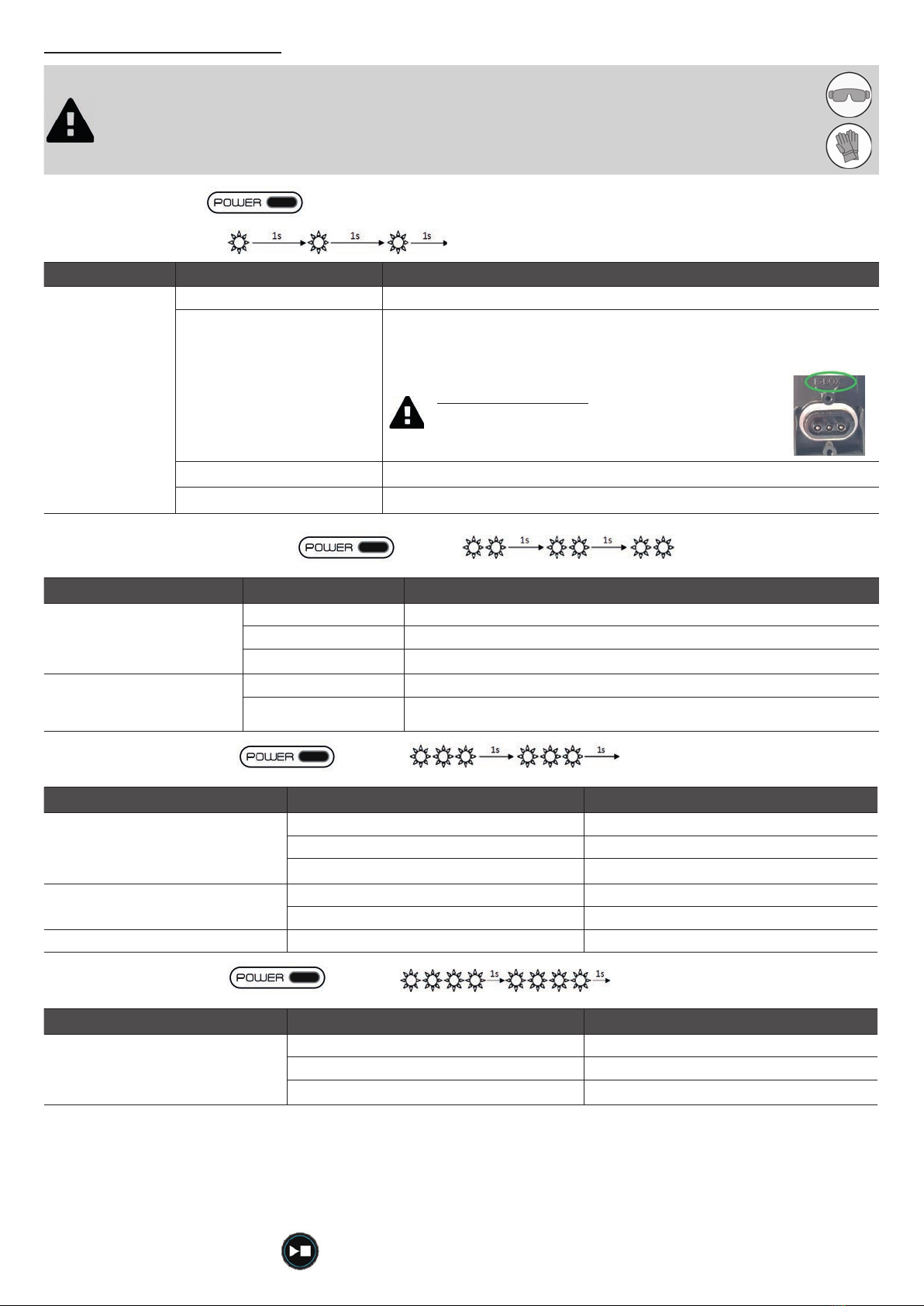

2. Cleaner diagnostics results

• Only a person qualifi ed in the technical fi elds concerned (electricity, hydraulics or refrigera on) is authorised

to carry out maintenance or repair work on the appliance. The qualifi ed technician working on the appliance

must use/wear personal protec ve equipment (such as safety goggles and protec ve gloves, etc.) in order to

reduce the risk of injury occurring when working on the appliance.

• Before handling the appliance, check that it is switched off and isolated.

"GOOD" message or lit steadily = Test OK

"Com FAIL" message or

Problems Possible origins Solu ons

Communica on

error

Unit connec on to the cleaner Disconnect and reconnect the unit to the cleaner

Condi on of the fl oa ng cable

Check the condi on of the fl oa ng cable. For a more accurate diagnosis of the

fl oa ng cable; Perform the test by connec ng another fl oa ng cable between the

control box and the motor unit.

Use the "E-BOX" connector and not "SENSOR" when

connec ng the cable to the motor unit (risk of damage to

components)

E-BOX

Faulty motor unit* Replace the motor unit

Water in the motor unit* Replace the motor unit

"tr1 FAIL"/"tr2 FAIL" message or fl ashing

Problems Possible origins Solu ons

Trac on 1 short circuit

Trac on 2 short circuit

Motor blocked Check whether there is any debris blocking the wheels, turn the wheels (¼ turn)

Water in the motor unit* Change the motor unit

Motor at end of life* Change the 2 trac on motors**

Trac on 1 overload

Trac on 2 overload

Motor blocked Check whether there is any debris blocking the wheels, turn the wheels (¼ turn)

Motor at end of life* Change the 2 trac on motors**

"Pump FAIL" message or fl ashing

Problems Possible origins Solu ons

Pump short-circuit

Motor blocked Check the fl ow guide and the propeller

Water in the motor unit* Change the motor unit

Motor at end of life* Change the pump motor

Pump overload Debris or hair stuck in the pump Check the fl ow guide and the propeller

Water in the motor unit* Change the motor unit

Pump underload Faulty pump motor* Change the pump motor

"Sens FAIL" message or fl ashing

Problems Possible origins Solu ons

Sensor unit malfunc on

Connec on of the sensor connector Check the connec on

Water in the sensor connector Replace the sensor

Sensor cable wear Check the condi on of the sensor cable

* Informa on intended for use by professionals.

** We recommend changing both trac on motors at the same me, because tests have shown that end of life-level wear occurs more or less at the

same me in both.

• Once the error has been resolved, it is recommended you start a new cleaner diagnos cs sequence, see “1. Cleaner

diagnos cs”.

• To exit diagnos cs mode, press .