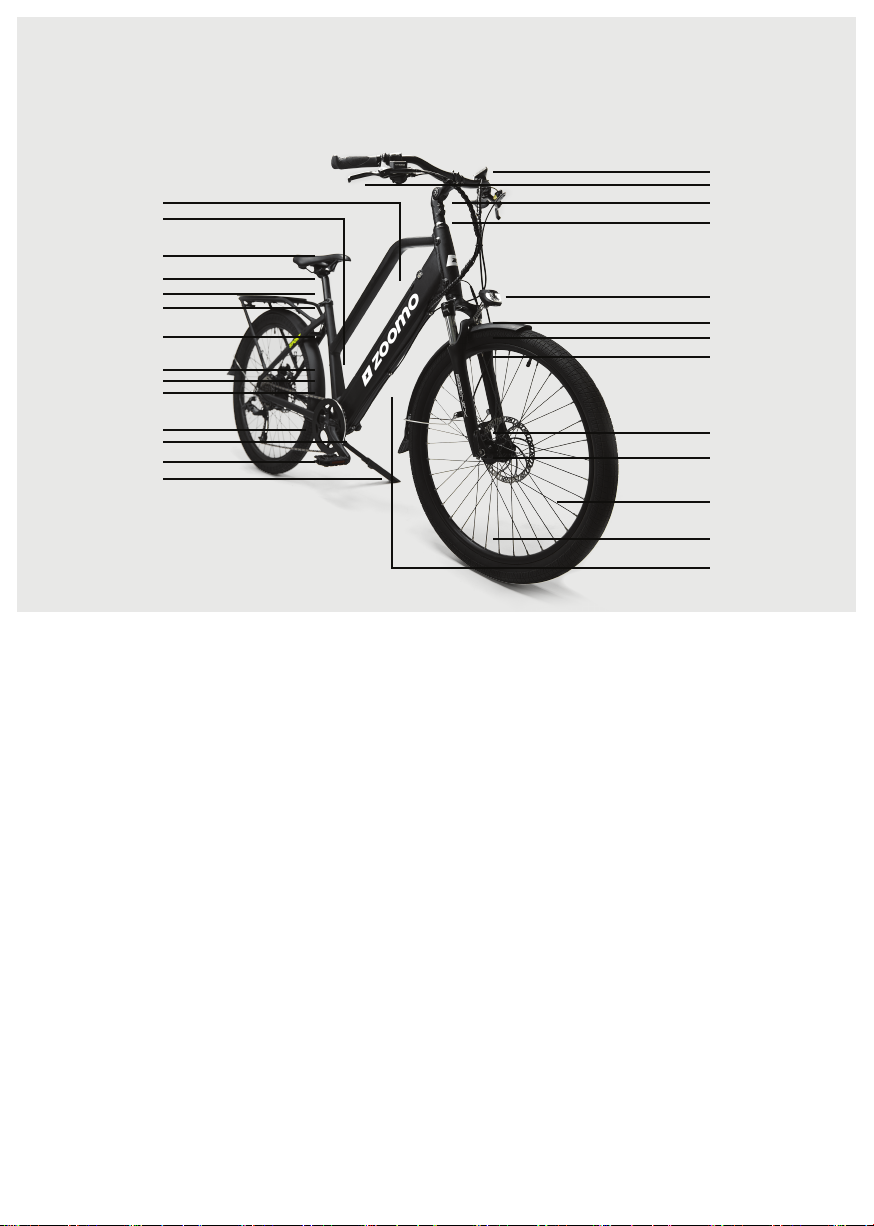

B. SETTING SADDLE POSITION

We have equipped our bikes with

ergonomic saddles, but a careful set up is

required to ensure optimal comfort. In

this section you will nd advice for an

angle and set back of your saddle, that’s

adjusted to the type of riding you do. It is

generally advised to position the saddle

horizontally for a mixed usage.

The saddle set back (position on the

horizontal slides) should be adjusted for

the length of the femur. In general an

intermediate setback is adequate as

shown in Figure 4 above.

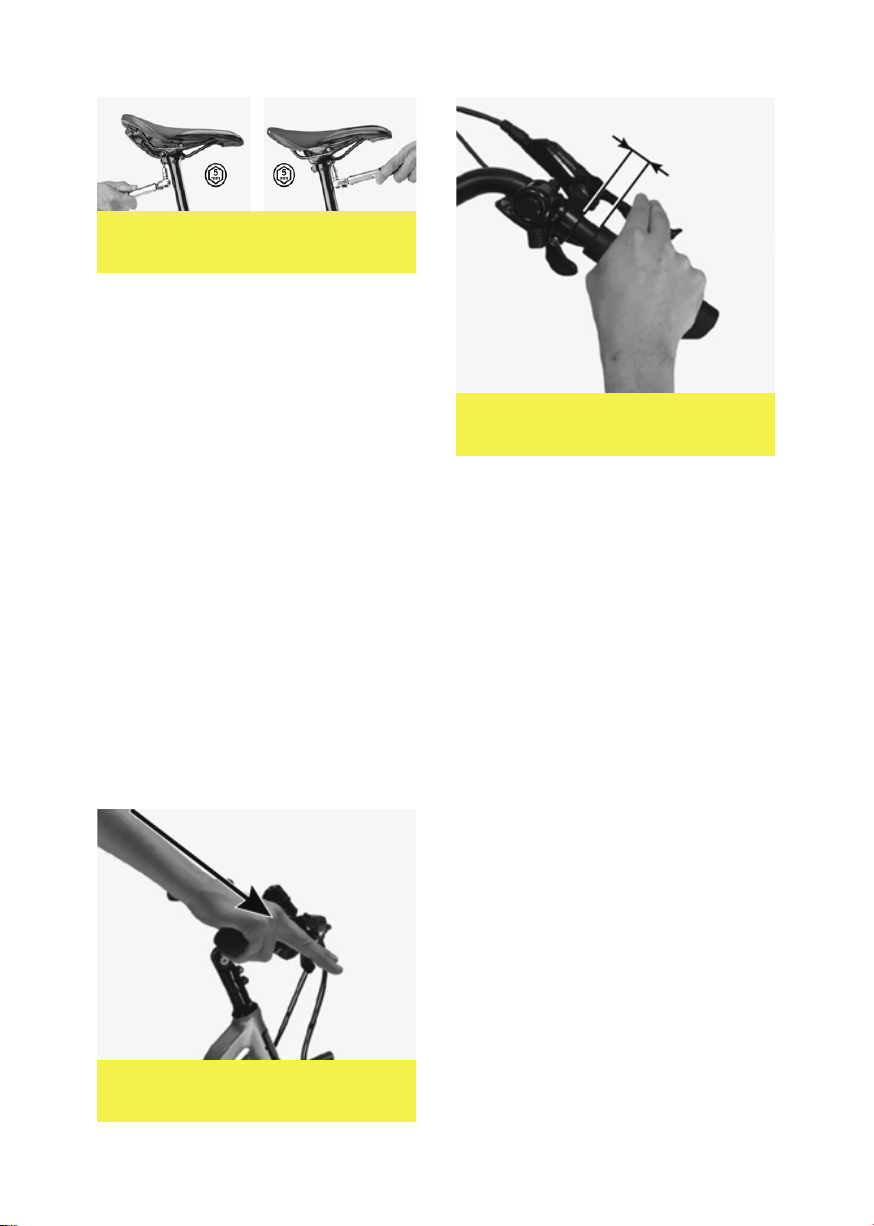

C. SETTING SADDLE ANGLE -

ONE BOLT

This applies if you nd a single bolt

underneath your saddle. To adjust the

angle of your saddle you need to carry

out the following process:

1. Loosen the screw that holds the

saddle and seat post using a 6 mm

allen key to obtain enough play to

easily move the saddle.

(see Figure 8)

Figure 4. Intermediate saddle

setback position.

2. Adjust the angle and setback of the

saddle as suits you.

3. Tighten the screw, ensuring that it

does not surpass the maximum

torque level indicated next to

the screw.

4. Check that the screw is correctly in

place and that there is no play.

D. SETTING SADDLE ANGLE -

TWO BOLTS

If you have found two tting bolts under

your saddle. To adjust the angle of your

saddle you need to carry out the

following process:

1. Loosen the two screws that hold the

saddle and seat post using a 5 mm

allen key (see Figure 9) until the

saddle can move easily.

2. Adjust the angle and setback of the

saddle as suits you.

3. Tighten each screw a half-turn,

alternating between the two,

without going over the maximum

torque level that is indicated next

to them.

4. Check that the saddle is correctly

in place and that there is no play.

Figure 5. Tightening / loosen

single saddle bolt.

06