Installation & maintenance manual

Knife gate valves Page 6

As a general rule, the valve should be installed vertically on horizontal pipe whenever possible.

However it is also possible to mount it in any other position as long as you consider that any

actuators fitted to the valve are adequately supported when the position is horizontal or

inclined.

Once the valve has been installed and securing the flanges are tight, operate the valve under

pressure and check the seal under load. It is important to note that during transportation or

storage of the valve the gland material might have settled so that in the event of leak, tighten

the gland nuts gradually and in a crosswise pattern. Only tighten just enough to prevent any

leakage, if the gland is overtighten, as this reduces the life of the gland and increase the force

required to operate the valve, possibly causing damage.

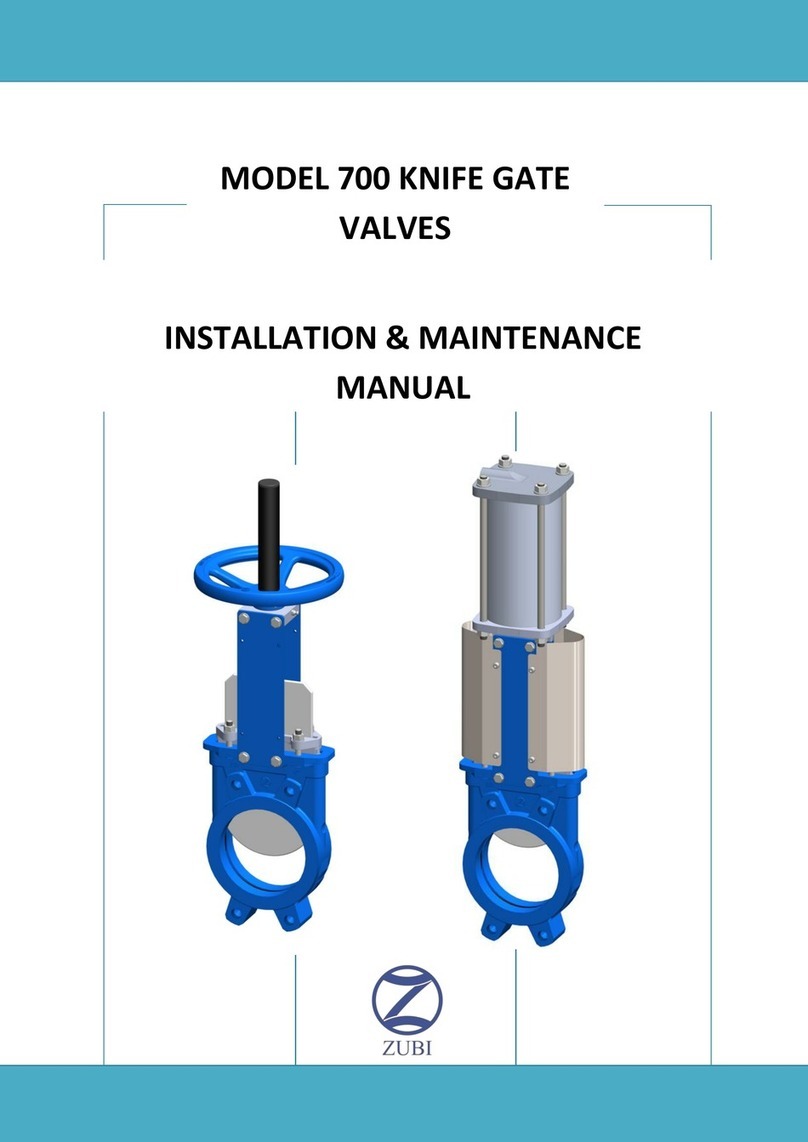

5. Actuators / Operation

Hand Wheel

To open the valve turn the hand wheel counterclockwise, to shut valve turn the hand wheel

clockwise.

Lever

To operate the valve first loosen the quick release locking screw and then operate the lever in

the direction of opening or closing. To secure the position tighten the quick release locking

lever.

Cylinder

For pneumatically operated valves, there are option for double-acting and single-acting, in

both cases the recommended air pressure is 5 to 6 bar.

We recommend that the compressed air is dry, filtered and lubricated for proper operation

and longevity of the cylinder.

Hydraulic

Where valves are operated with hydraulic cylinders is important to use clean hydraulic and to

maintain the cylinders on a regular basis. It is recommended specifying low temperature oils in

areas where the valves are constantly exposed to cold temperatures.

Gear-box

The operation with a gearbox is similar to the drive wheel. For best performance it is

recommended to lubricate the gear every six months. Where valves are in storage it is

recommended to operate every 4 months.

Electric

Recommended electric actuator rpm for Zubi T200 valve is 45rpm, higher speed rpm under

end user responsibility.