Zumex

Gr

oup

S.A.

Tel. +34 961 301 251 · Fax. +34 961 301 255 · [email protected] · Zumex Service Tel: +34 960 800 999 · www.zumexfoodengineering.comDismantling and cleaning for every use juice recepit

Mastery dismantling, cleaning and maintenance guide

Cleaning and sanitizing warnings

!

!

1

7

4

2

8

5

3

9

6

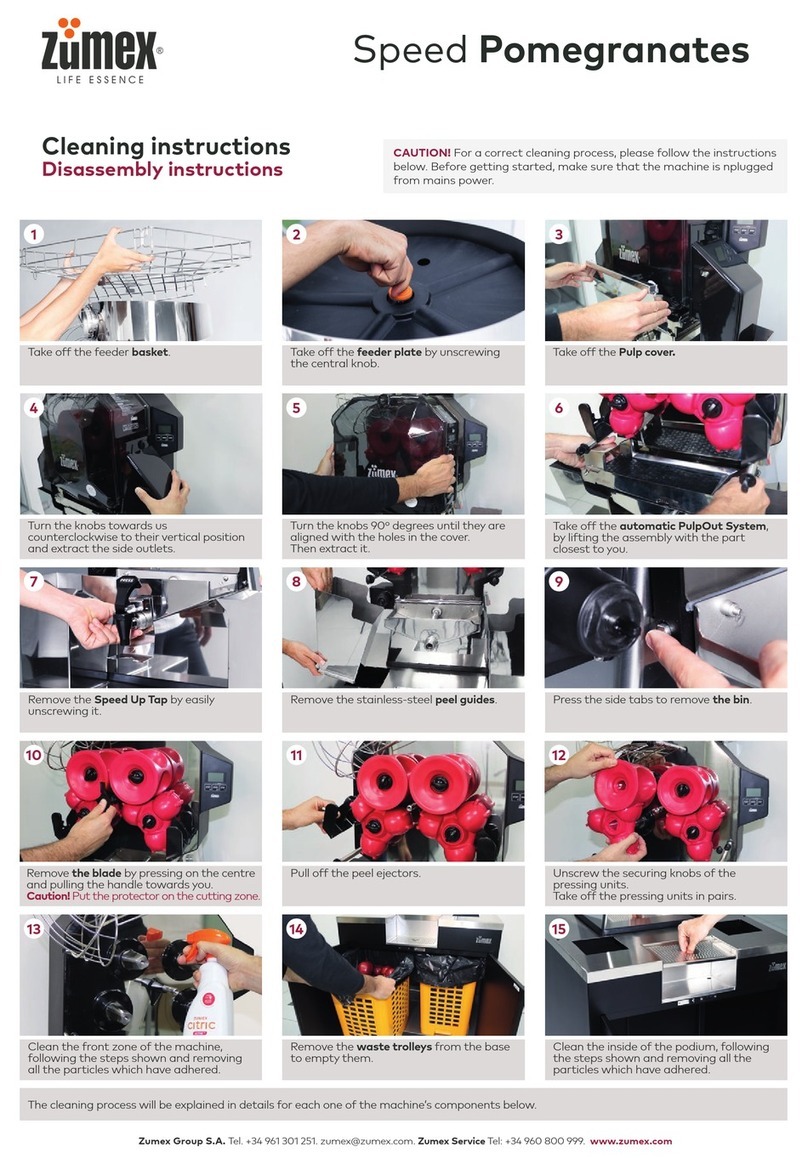

We stop the machine. We open the shredder

door, opening each one of the closures.

Unlock the feeding hooper through the loc-

ker, placing from right to left.

We place the filter bag in the header shred-

der and in the back side.

We remove it the gasket and place it in a

wash point.

On right side, move the locker towards you

and up the head shredder.

We remove the pulp from the pulp box, ha-

ving previously checked that the filter bag is

in its correct position. **

Disassemble the disc shredder support to-

gether with the shredder blade, turning the

central torque - turn to the right. *

Open the pulp box and move the content in

order to ease the waste discharge.

We take one of the cleaning brush with the

supplied brush 1 to descale the fruit adhered

both in the machine and in the accessories.

*Do not lose the central clamping nut.

** It is only necessary to perform this action once finished the operation or when changing the recipe.

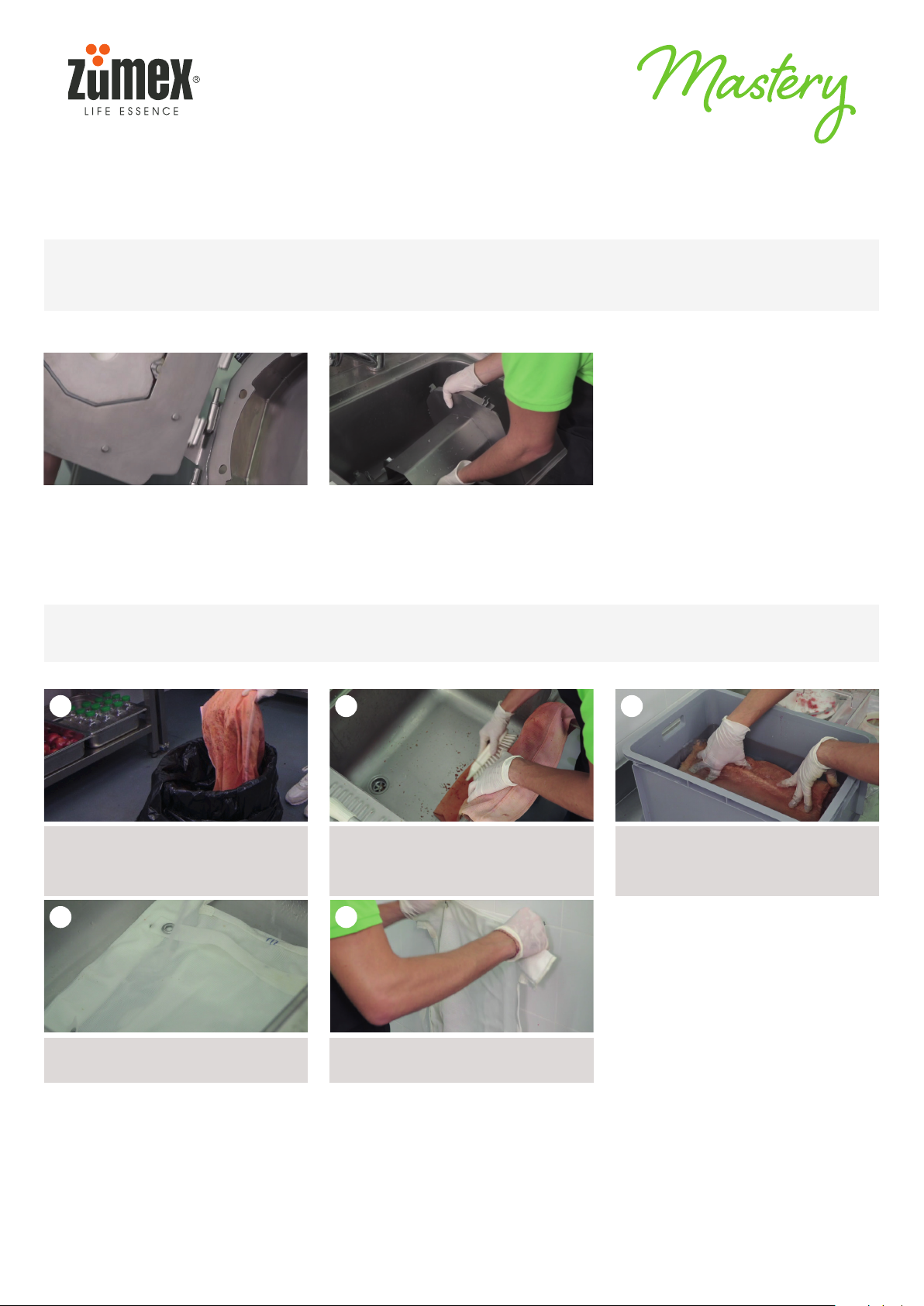

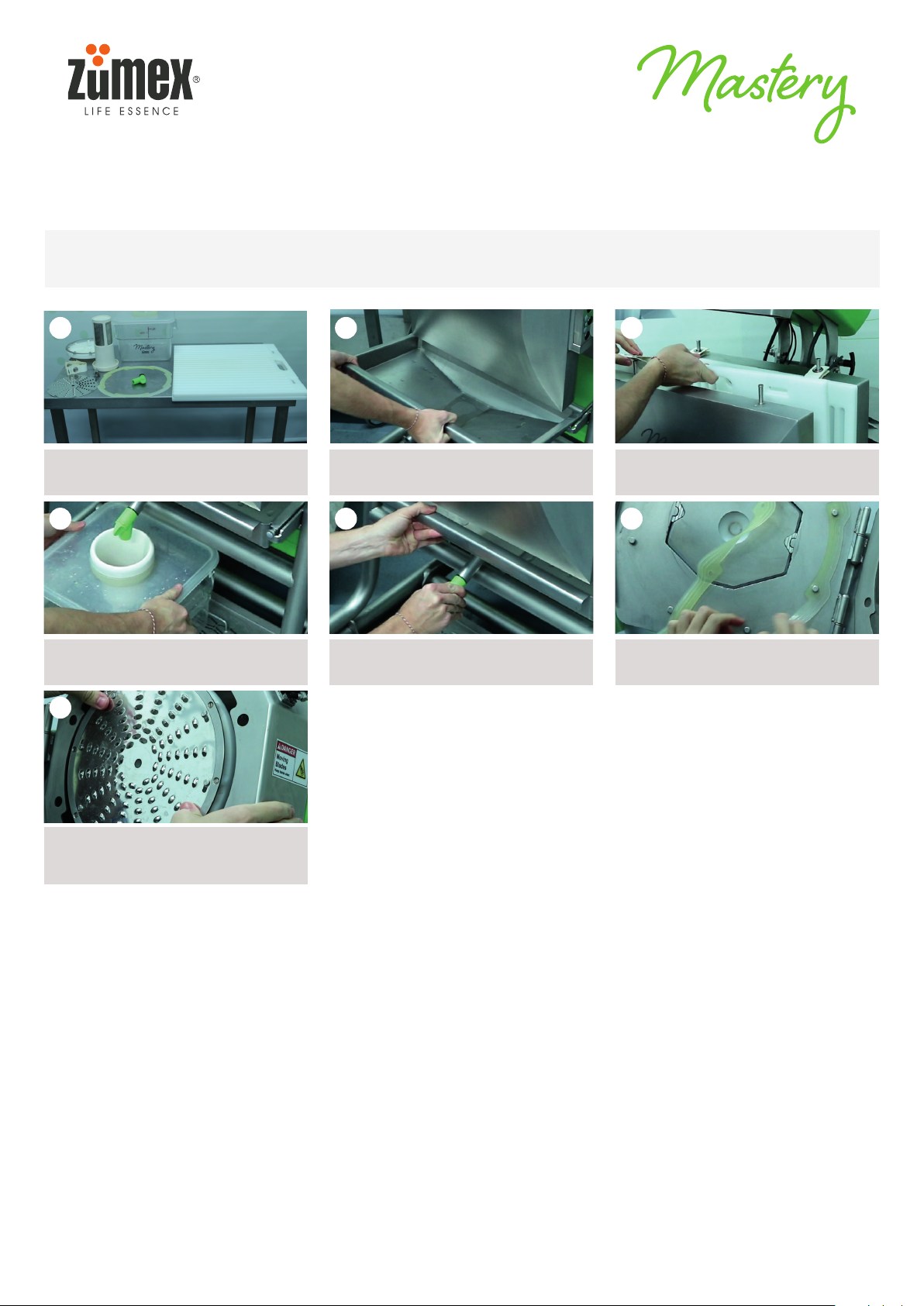

The following document will guide you on the systematic process both to keep your machine in the best conditions.

For the cleaning and dismantling process, we must provide safety tools, such as gloves and goggles to avoid damage.

We determine what is the cleaning that must be done according to the frequency:

• Cleaning for each practice.

• Cleaning for the end of the day.

• Biweekly cleaning.

• Monthly cleaning.