To avoid potential residual risks the user should read and understand the following

safety measures ( you are strongly advised to read this before using the machine ).

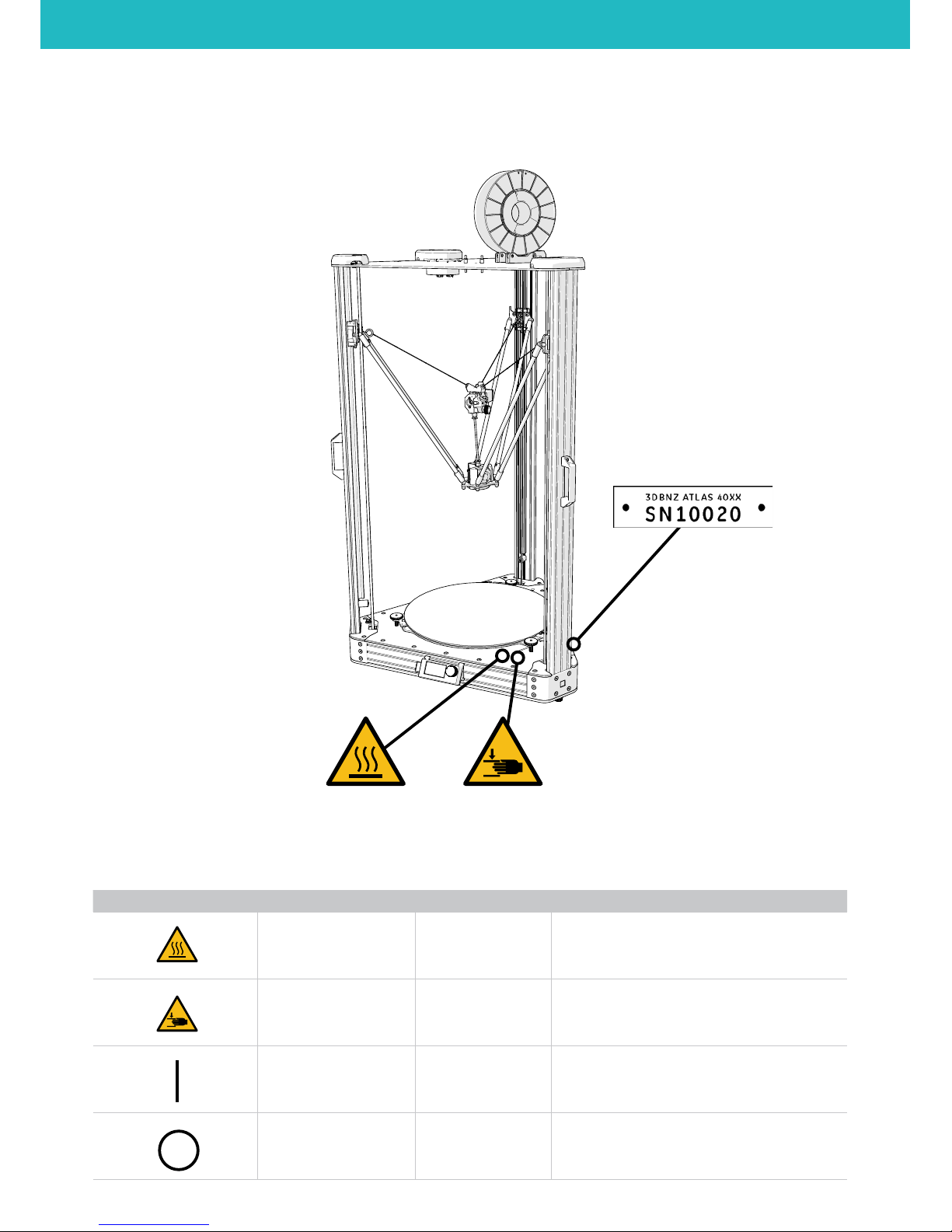

To highlight the areas where extra care should be taken, safety alert stickers have been

axed to the relevant parts of the machine to warn the user of potential hazards.

Any modications made to the machine without the manufacturer´s approval will

invalidate the product´s warranty.

Consequently, BNZ3D ARE EXEMPT FROM ANY LIABILITY IF THE USER DOES NOT FOLLOW

THE INSTRUCTIONS FOR USE:

SAFETY GUIDELINES & WARNINGS

The following safety guidelines, as well as the instructions within

this user manual, ensure the safety of the user while operating and

maintaining the ATLAS printer. If the printer is not operated as

specied, the operator’s safety may be compromised.

First Aid

• All operators should have access to rst aid equipment and

know how to use it.

Installation

• Connect the printer to the safety-certied power cord supplied

with the machine. The electrical outlet should be near the

printer and easily accessible.

• Never connect the printer to an outlet that does not have a

ground wire. Disconnecting the ground wire may result in

electric shock.

Operation

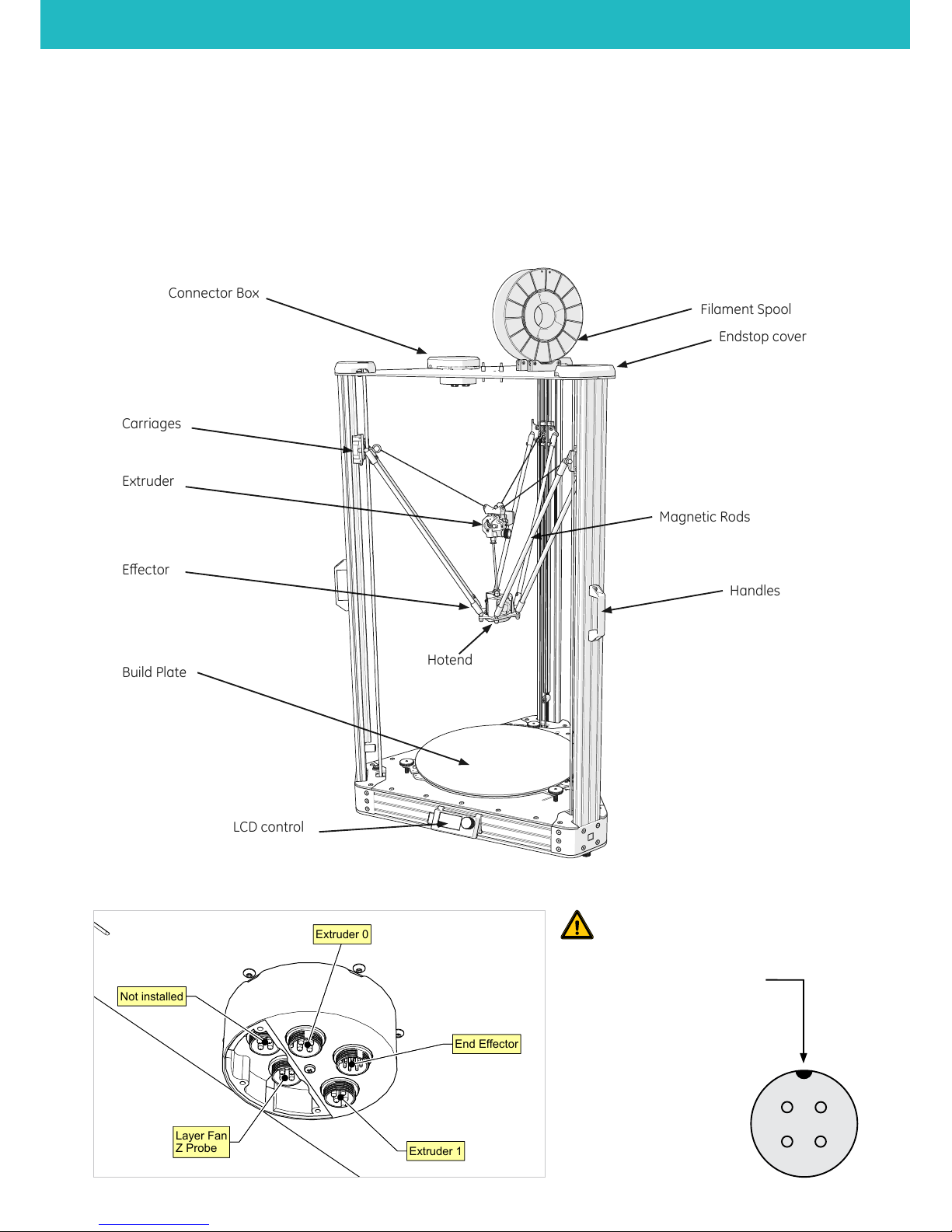

• The 3DBNZ ATLAS printer generates high temperatures in the

print nozzle and the print bed—do not touch when hot. Allow

the unit to cool before touching.

• Do not set objects on the heated print bed. Do not lean or

stand on the print bed. Doing so may cause injury to the

operator.

• Due to high temperature outputs and moving parts, the

location where the printer is operating should be equipped

with working smoke and ame detection.

• The 3DBNZ ATLAS printer melts material during printing. Some

materials may require ventilation.

• Do not leave the 3DBNZ ATLAS printer unattended while in

operation.

• The 3DBNZ ATLAS includes linear actuators that move in

multiple directions at variant speeds. When in motion, they

may cause injury.

• Do not place head or any other body part near the print head

or nozzle, as injury may occur if pinched between the print bed

and the nozzle.

• In case of emergency, unplug the unit from the electrical

outlet.

Maintenance

• All maintenance shall be performed according to the

manufacturers guidelines and instructions. Failure to follow

the guidelines may cause injury.

• When maintaining equipment that is hot, wear gloves to avoid

injury.

INTENDED USE

Each 3DBNZ ATLAS 3D printer is tested, prior to shipment, to ensure

proper functionality.

• This printer is intended for professional use by an operator

with the ability to read instructions, having basic/low level

knowledge of electronics, mechanics, and computers in

general.

• Intended for printing 3D objects with materials manufactured

for the FFF—fused lament fabrication—type of 3D printing.

• To be operated under normal operating conditions as specied

within this manual.

• Not intended to be used by children or persons not familiar

with the operating and safety instructions. Use by unqualied

persons may be dangerous to the user and/or damaging to

the printer. Printer damage due to mis-use is not covered by

the warranty.

• Any modications to the 3D printer are at your own risk and

will void the warranty. The manufacturer cannot be held

responsible for modications made by other persons.

ATLAS SERIES Safety Guidelines & Warnings

4