Contents

I INTRODUCTION ............................................................................................................................................................................4

1. INTRODUCTORY COMMENTS.................................................................................................................................................4

2. MATERIALS FOR PRINTING.....................................................................................................................................................4

3. SYMBOLS ................................................................................................................................................................................5

3.1. List of symbols used in the manual.................................................................................................................................5

3.2. Indicator lights ................................................................................................................................................................6

4. SAFETY MEASURES.................................................................................................................................................................6

4.1. General information .......................................................................................................................................................6

4.2. Relocating the printer.....................................................................................................................................................7

4.3. Choosing proper installation place for the printer .........................................................................................................8

4.4. Before starting the printer............................................................................................................................................10

II DESCRIPTION OF PRINTER .........................................................................................................................................................11

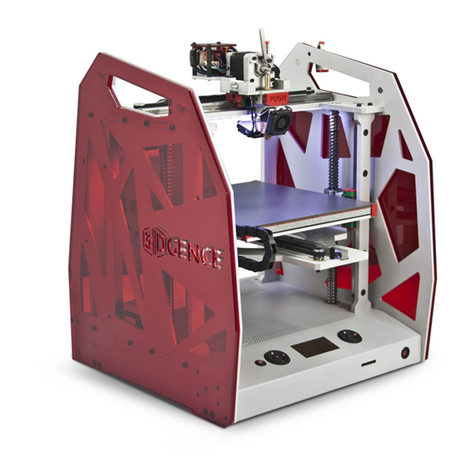

1. CONSTRUCTION OF PRINTER ...............................................................................................................................................11

2. CONTENTS OF EQUIPMENT..................................................................................................................................................14

3. USER INTERFACE ..................................................................................................................................................................16

3.1. Main panel....................................................................................................................................................................16

3.2. PAUSE and START buttons ............................................................................................................................................17

3.3. LCD display....................................................................................................................................................................17

3.4. MENU............................................................................................................................................................................19

III PREPARATION FOR WORK ........................................................................................................................................................24

1. FIRMWARE UPDATE .............................................................................................................................................................24

2. CONNECTING AND STARTING PRINTER ...............................................................................................................................24

3. CALIBRATION OF HEATBED ..................................................................................................................................................25

3.1. Indication for calibration of heatbed............................................................................................................................25

3.2. Heatbed calibration procedure ....................................................................................................................................25

4. PRINTING MATERIAL APPLICATION PROCEDURE.................................................................................................................26

4.1. Mounting filament........................................................................................................................................................27

4.2. Filament removal..........................................................................................................................................................28

4.3. Changing filament during printing................................................................................................................................28

IV FIRST PRINTOUT .......................................................................................................................................................................30

1. LAUNCHING SD CARD CODE.................................................................................................................................................30

2. EVALUATION OF OPERATIONAL QUALITY OF PRINTER ........................................................................................................31

V SOFTWARE ................................................................................................................................................................................32

1. INTRODUCTION....................................................................................................................................................................32

1.1. Quality guarantee .........................................................................................................................................................32

2. INSTALLATION ......................................................................................................................................................................32

VI POST PRINTING OPERATIONS ..................................................................................................................................................33

1. REMOVING THE PRINTOUT FROM THE DEVICE ...................................................................................................................33