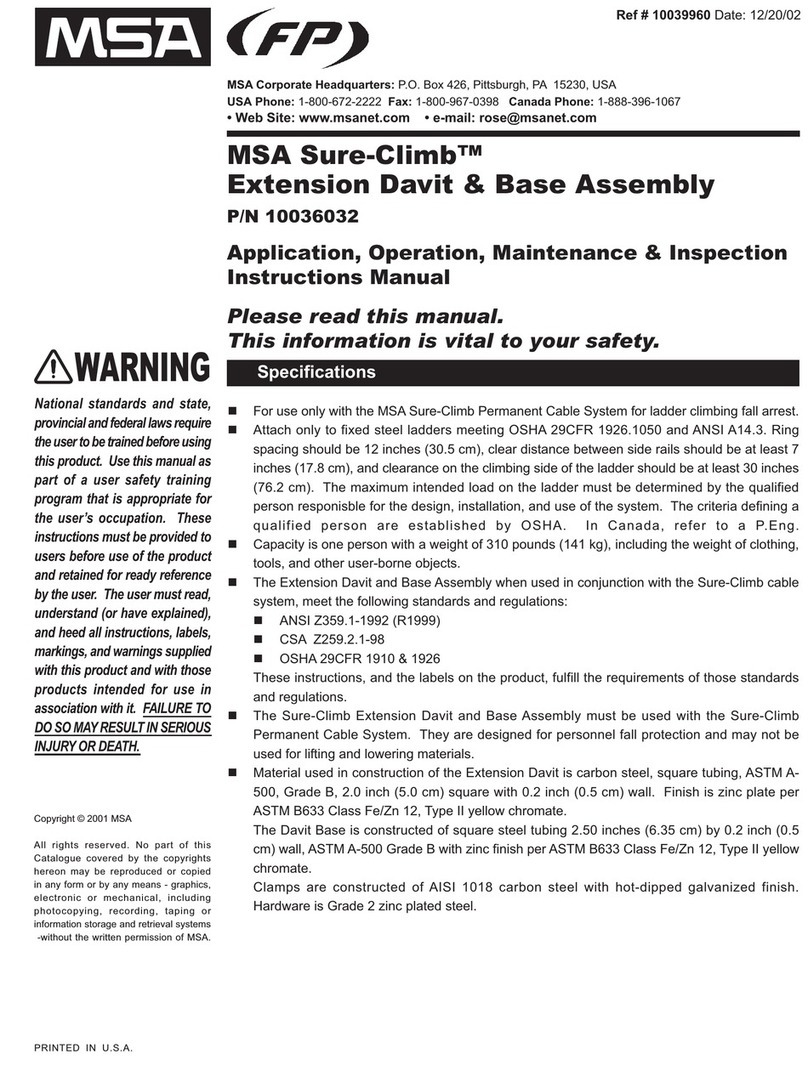

Page 6 of 8 Copyri ht © 2001 MSA Surety

Design Statements

Inspection

1. Shock loadin should be avoided at all costs, however,

the system has been desi ned to have a lar e

stren th safety mar in. In the event of shock loadin ,

dama e to the rope is likely and any rope subjected

to shock loadin must be removed from service.

2. Use only equipment included with the MSA

SuretymanRescue Utility System or MSA approved

accessories. If this warnin is i nored by the end user,

the user and the users mana ement accepts all liability.

3. Reduction of the rope stren th can result from

sharp ed es, overloadin , shock loadin and/or

incorrect stora e. Care of the rope is critical to avoid

dama e to the rope which could reatly reduce

system stren th.

4. The system should be used as supplied by the

manufacturer. Only qualified individuals are to re-ri

or re-rope the MSA Suretyman Rescue Utility

System.

5. A small force of approximately 7 % is all that is

required to hold or lower a load usin the MSA

Suretyman Rescue Utility System. Should the rope

become heavily soiled this friction could increase.

A sli htly soiled or wet rope should not effect the

systems function, however if the rope becomes

extremely soiled the MSA SuretymanRescue Utility

System may become inoperable. Always try to keep

the rope clean and dry to avoid any unwanted

increases in friction.

1. The MSA Rescue Utility System shall be inspected by

the user prior to each installation, and additionally by

a competent person other than the user at intervals of

not more than one year. Inspections of the rope must

be recorded in the Inspection Checklist.

2. When inspection reveals defects, dama e, or

inadequate maintenance of any component in the

system, the component affected shall be removed from

service and under o adequate corrective maintenance

before return to service. Removal from service may

imply that defects or dama e will result in retirin and

replacin some components.

3. Remove a unit from service if any of the components

fall into a cata ory below:

markin s (labels) are ille ible or absent;

there is evidence of excessive wear or dama e to

the rope;

there is evidence of defects or dama e to hardware

elements includin cracks, sharp ed es, deformation,

corrosion, chemical attack, excessive heatin ,

alteration or excessive wear;

there is evidence of improper function, improper fit

or alteration of any mechanical component;

there are parts missin .

4. MSA or persons or entities authorized in writin by the

manufacturer, shall make repairs to equipment. No

unauthorized repairs and/or modifications are allowed.

Procedure

1. Inspect the system prior to use and each time the

system is moved to a new anchor location. Look for

evidence of cuts, wear, frayin , rease, oil, lue, tar,

or any other conditions which could affect the

performance of the controller or stren th of the pulleys.

Inspect shrink seal and thimble on both ends of rope

for dama e. If shrink seal is missin , knot may have

been tampered with.