Hacousto Holland bv

Industrieweg 87

2651BC Berkel & Rodenrijs

IMPACT reference system manual (Typical )

Table of Contents

!General information ............................................................................................................................................................. 3!

!Controller ....................................................................................................................................................................... 3!

!DCA2.500 amplifier / charger .................................................................................................................................. 5!

!4E-SW6 zone expander with line monitoring .................................................................................................... 5!

!Expander – network port extender for L-Net devices ..................................................................................... 6!

!Examples of Impact system ....................................................................................................................................... 7!

!Where do I start? ................................................................................................................................................................... 8!

!Configuration settings ......................................................................................................................................................... 8!

!Impact system build ............................................................................................................................................................. 9!

!Rack frame ..................................................................................................................................................................... 9!

!DIN-rail enclosure for remote network devices ................................................................................................ 9!

!Additional electrical safety requirements for the housing ............................................................................ 11!

!Connections ................................................................................................................................................................. 11!

4.4.1.!Mains ................................................................................................................................................................ 12!

4.4.2.!Battery .............................................................................................................................................................. 12!

4.4.3.!Battery temperature probe ....................................................................................................................... 13!

4.4.4.!DC power output .......................................................................................................................................... 14!

4.4.5.!AMP LINK ........................................................................................................................................................ 14!

4.4.6.!Network ports ................................................................................................................................................ 16!

4.4.7.!L-Net (local network) ................................................................................................................................... 17!

4.4.8.!EVAC inputs .................................................................................................................................................... 17!

4.4.9.!Amplifier 100V outputs ............................................................................................................................... 18!

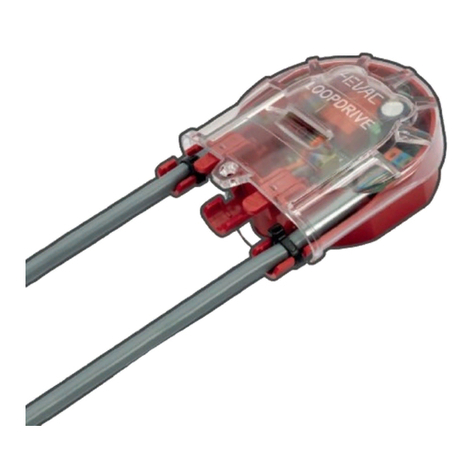

4.4.10.!Loudspeaker lines ................................................................................................................................ 19!

4.4.11. .......................................................................................................................................................................... 20!

!Connections and recommended cable types ............................................................................................................ 20!

!Maintenance information .................................................................................................................................................. 21!

!Additional RACK marking .................................................................................................................................................. 21!

!Typical Technical and Electrical specifications. .......................................................................................................... 23!