a-eberle Low Voltage Regulation System User manual

Installation manual

LVRSys™ - 3-phase systems

Low Voltage Regulation SystemTM

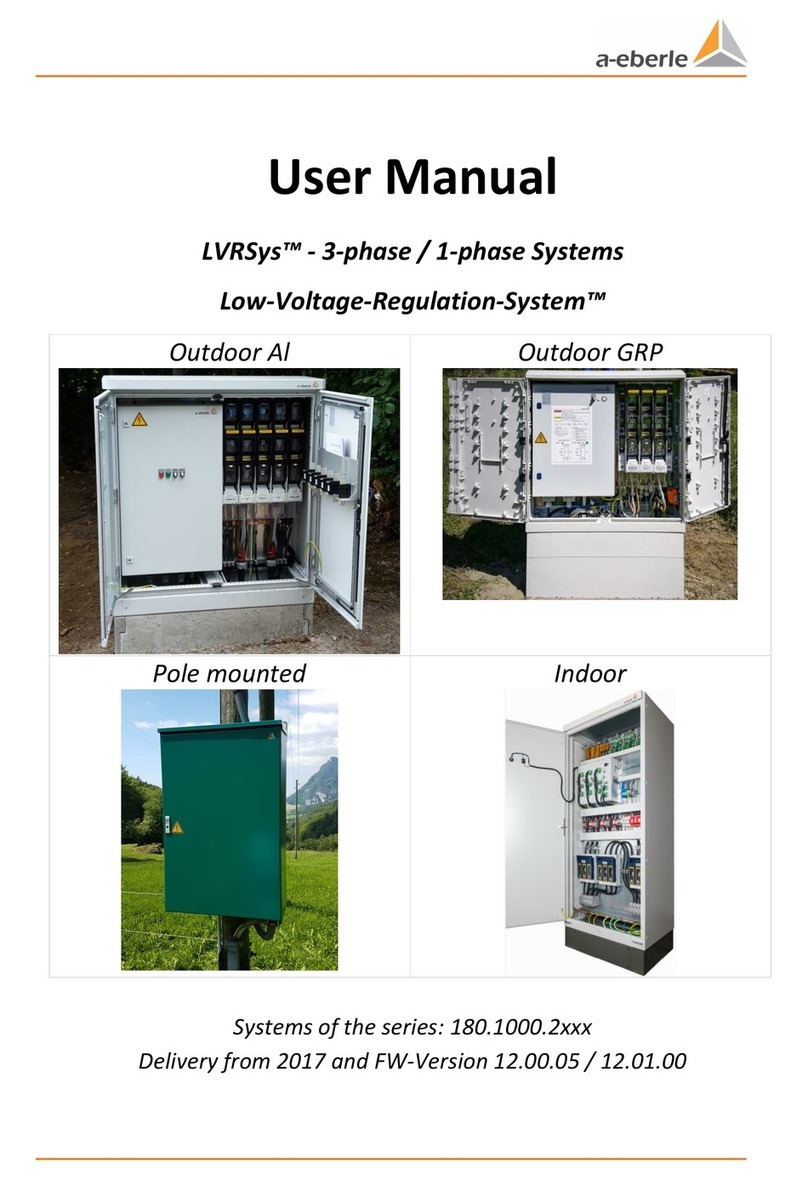

Outdoor installation Al

Outdoor installation GRP

Pole mount

Indoor installation

Systems of the series: 180.1000.2xxx

Delivered from III/2019

Page 1

Contents

1. User guidance ................................................................................................................ 3

1.1 Target group..............................................................................................................................3

1.2 Warnings ...................................................................................................................................3

1.3 Tips............................................................................................................................................3

1.4 Other symbols...........................................................................................................................4

1.5 Other applicable documents.....................................................................................................4

1.6 Storage ......................................................................................................................................4

2. Scope of delivery/options............................................................................................... 5

3. Packaging....................................................................................................................... 6

3.1 Control cabinet .........................................................................................................................6

3.2 Transformer block.....................................................................................................................7

3.3 Concrete/GRP base ...................................................................................................................7

4. Transport....................................................................................................................... 8

4.1 Transport with pallet.................................................................................................................8

4.1.1 Switch cabinet transport on pallet............................................................................................8

4.1.2 Transformer transport with pallet (only outdoor-systems)......................................................9

4.1.3 Base transport with pallet.........................................................................................................9

4.2 Lifting devices............................................................................................................................9

4.2.1 Use of a crane and the lifting lugs of the Aluminum switch cabinet ........................................9

4.2.2 Switch cabinet GRP ................................................................................................................ 11

4.2.3 Installing the Switch cabinet indoors using a crane and the lifting lugs................................ 12

4.2.4 Pole Mount cabinet with crane lugs ...................................................................................... 13

4.2.5 Lifting the Transformer with a crane using the lifting lugs.................................................... 13

4.2.6 Concrete base ........................................................................................................................ 14

5. Installation....................................................................................................................15

5.1 Fuse protection ...................................................................................................................... 16

5.1.1 Fuse protection for systems with switch-disconnector-fuses ............................................... 16

5.1.2 Fuse protection for systems with NH disconnectors............................................................. 17

5.1.3 Fuse protection for systems with automatic circuit breakers ............................................... 17

5.2 Fuse protection (internal side)............................................................................................... 18

5.3 Systems outdoor installation ................................................................................................. 19

5.3.1 Outdoor installation requirements........................................................................................ 19

5.3.2 Ground hole for concrete base and GRP base....................................................................... 19

5.3.3 Concrete Plinth mounting...................................................................................................... 20

5.3.4 GRP base mounting................................................................................................................ 23

Page 2

We take care of it.

5.3.5 Inserting the transformer block & if applicable, the preliminary stage .................................26

5.3.6 Filling layer around the plinth.................................................................................................27

5.3.7 Mounting the switch cabinets for outdoor installation onto a base......................................27

5.3.8 Locking the switch cabinets - outdoor installations ...............................................................28

5.3.9 Connection of the transformer block to the control unit.......................................................29

5.3.10 Connection of the low voltage cables & grounding................................................................31

5.4 Systems for indoor installation...............................................................................................41

5.4.1 Requirements for indoor installation .....................................................................................41

5.4.2 Base mounting ........................................................................................................................41

5.4.3 Transformers...........................................................................................................................41

5.4.4 Mounting the base LVRSys™indoor installation on the floor ................................................41

5.4.5 Connecting the low-voltage cables.........................................................................................42

5.5 Pole mount Systems ...............................................................................................................46

5.5.1 Mounting the LVRSys™on the pole........................................................................................46

5.5.2 Connecting the low-voltage cables on the grid side...............................................................50

5.6 External installations...............................................................................................................51

6. Commissioning & Decomissioning LVRSys™................................................................... 52

6.1 Lights & Switches ....................................................................................................................52

6.2 Commissioning and decomissioning LVRSys™........................................................................52

6.3 Check that there is no voltage ................................................................................................54

6.4 Current transformer N/PEN-rail..............................................................................................54

6.5 Operation of circuit breakers and switch disconnectors........................................................55

6.5.1 Operation of systems with circuit breakers............................................................................55

6.5.2 Operation of systems with switch disconnectors...................................................................56

6.5.3 Operation of systems with LV fuse-switch-disconnectors......................................................59

Page 3

1. User guidance

The installation manual contains all the important information for installation,

commissioning and operation.

Read the installation manual completely and do not use the product until you have

understood the installation manual.

1.1 Target group

This installation manual is intended for trained specialist personnel as well as trained and

tested operating personnel.

The content of this installation manual must be made accessible to the persons responsible

for the installation and operation of the system.

1.2 Warnings

Structure of the warnings

Warnings are structured as follows:

SIGNAL WORD!

Type and source of danger!

Consequences of non-compliance.

Measures to avoid the danger.

Gradation of the warnings

Warnings differ according to the type of hazard as follows:

DANGER!

Warns of an imminent danger leading to death or serious injury if not

avoided.

WARNING!

Warns of potentially hazardous situation leading to death or serious

injury if not avoided.

CAUTION!

Warns of a potentially hazardous situation leading to moderate or

minor injury if not avoided.

ADVICE!

Warns of potentially hazardous situation that, if not avoided, may

result in damage to property or the environment.

1.3 Tips

Tips for proper use of the device and recommendations.

Page 4

We take care of it.

1.4 Other symbols

Instructions

Structure of the instructions:

Instructions for an action.

Result of action if necessary.

Lists

Structure of unnumbered lists:

0List level 1

–List level 2

Structure of numbered lists:

1) List level 1

2) List level 1

1. List level 2

2. List level 2

1.5 Other applicable documents

For safe and correct use of the system, also observe the additional documents supplied as

well as relevant standards and applicable local regulations.

1.6 Storage

Keep the installation manual, including all applicable documents, in close proximity to the

LVRSys system.

Page 5

2. Scope of delivery/options

The LVRSys systems are built up as a modular system. The main components & documents

are:

0LVRSys™ control unit (for installation in external control cabinets)

0Transformer block

0Control cabinet for outdoor or indoor installation or pole mount

0Base for outdoor installation

0Operating instructions LVRSys™

0Installation manual LVRSys™

0Circuit diagram of the control cabinet LVRSys™

0Test certificate LVRSys™.

Page 6

We take care of it.

3. Packaging

3.1 Control cabinet

The switch cabinet are packed in foil, cardboard or wood (selected order feature), standing

on pallet.

Wood packaging

Figure 3-1 Switch cabinet packed in wood (example)

For special regulations (e.g. export) the packaging may differ.

Figure 3-2 Packaging & shock sticker

To protect the system, the packaging consists of particle board pieces.

Before opening the crate, check the shock sticker

ADVICE!

If the sticker is RED:

Do not remove packaging.

Contact A. Eberle GmbH & Co. KG for further information.

Page 7

3.2 Transformer block

0Outdoor installation

The transformer block is packed in foil, cardboard or wood (selected order feature), lying on

pallet.

3.3 Concrete/GRP base

0Outdoor installation

The base is packed in foil (concrete base), cardboard (GRP-base) or wood (selected order

feature), lying on pallet.

Page 8

We take care of it.

4. Transport

4.1 Transport with pallet

4.1.1 Switch cabinet transport on pallet

With the exception of systems for pole mounting, all switch cabinets must be transported

vertically. Pole mounting systems can also be transported horizontally.

CAUTION!

Avoid damage to the switch cabinet due to incorrect handling

during transport!

Only Transport the switch cabinet upright.

Ensure that the switch cabinet cannot tip over while in transit.

Fasten mounting devices on the board wall.

Figure 4-1 Cabinet transport on truck

Page 9

4.1.2 Transformer transport with pallet (only outdoor-systems)

CAUTION!

Avoid damage to the transformer block due to incorrect handling

during transport!

Transport transformer block in horizontal position only.

Ensure the holding devices are fastened to the tailboard.

4.1.3 Base transport with pallet

No special transport sensitivities.

4.2 Lifting devices

DANGER!

Danger to life if the switch cabinet is dropped during lifting!

Ensure that no body is standing under or nearby to the

suspended load.

CAUTION!

Damage to the system if the control cabinet is dropped!

Always secure the LVRSys™ switch cabinet by the lifting lugs.

Only lift the cabinet vertically (deviation up to a maximum of 60°)

to the lifting lugs.

Ensure the lift upward of the LVRSys™ switch cabinet is done

smoothly without any jerks.

4.2.1 Use of a crane and the lifting lugs of the Aluminum switch cabinet

Transport lugs are located under the weather protection roof.

Removing the weather protection roof:

Loosen the screws at the front (1).

Lift the hood at the front (2).

Push the hood to the back (3).

Lift the hood upward (4).

Installing the weather protection roof:

Lower the hood from above (5).

Push the hood to the front (6).

Fasten the screws at the front (7).

Page 10

We take care of it.

Figure 4-2 Installing and removing the weather protection roof

The screws can be loosened and fastened with a TX 25 screwdriver. The tightening torque

may not exceed 6 Nm.

Use all four transport lugs.

1

2

3

4

5

6

1

2

7

Page 11

Figure 4-3 Transport lugs

4.2.2 Switch cabinet GRP

CAUTION!

Damage to the switch cabinet can occur through incorrect handling

during transit!

Only transport the switch cabinet in an upright position.

Ensure that the switch cabinet cannot tip over.

Ensure fastening of holding devices to the tailboard.

Use mobile crane lugs

Then seal the switch cabinet with blind plugs

Figure 4-4 mobile crane lugs

Page 12

We take care of it.

4.2.3 Installing the Switch cabinet indoors using a crane and the lifting lugs

DANGER!

Danger to life if the switch cabinet is dropped!

Ensure that nobody is standing nearby or under the

suspended load.

Figure 4-5 Lifting eyes distribute the weight being lifted

CAUTION!

Damage to the system will occur if the switch cabinet is dropped !

Always secure the LVRSys™ switch cabinet with all lifting lugs.

Only lift the cabinet up vertically (deviation up to a maximum of

60°) to the lifting lugs.

Lift the LVRSys™ switch cabinet up smoothly avoiding any jerks.

Systems with more than 800 kg can only be lifted vertically –

straight up!

CAUTION!

Damage to the system will occur if the switch cabinet is dropped!

Always move the LVRSys™ switch cabinet smoothly & evenly.

Page 13

4.2.4 Pole Mount cabinet with crane lugs

Two mobile crane lugs are installed on the upper edge of the control cabinet. These are

intended to lift the system.

Abbildung 4-6 mobile crane lugs

4.2.5 Lifting the Transformer with a crane using the lifting lugs

Systems with a preliminary stage and two transformer blocks must be lifted into the ground

base.

DANGER!

Risk of fatal injury if the transformer block is dropped !

Ensure that nobody is standing nearby or under a

suspended load.

CAUTION!

Damage to the system if the transformer block is dropped!

Always secure transformer block using all lifting lugs provided.

Only lift or lower the transformer block in a vertical movement

(deviation up to a maximum of 60°) to the lifting eyes.

Ensure the lifting is done smoothly without any jerks to the

transformer block.

Page 14

We take care of it.

Figure 4-7 Transformer block with four lifting lugs

Use all four lifting lugs.

4.2.6 Concrete base

DANGER!

Risk of fatal injury if the concrete base is dropped or falls over!

Ensure that nobody is standing close-by or under

a suspended load.

There are no special transport considerations.

Page 15

5. Installation

DANGER!

Risk of death due to electric shock!

Only install LVRSys™ in a de-energised state.

CAUTION!

Destruction of components by short-circuit forces!

Use cable clamps in the in- and output of the LVRSys™.

CAUTION!

Destruction of components due to overload!

Only connect the low-voltage grid in BYPASS operation.

(See chapter 6.2)

Sequence for the connection to the low-voltage grid:

Disconnect the low-voltage grid.

Installing the system

Check assembly

Make sure that the system is in Bypass mode

Connect the low-voltage grid.

NOTE!

Aluminum con-

ductor

For direct connection terminals

With aluminum conductors, the oxide layer must be mechanically

removed immediately before contacting and treated with acid- and

alakali-free grease.

The installation location must be kept as free as possible from mois-

ture or aggressive atmosphere.

If an aluminum conductor is used, the screw in the terminal body of

the screw terminal must be tightened to the maximum permissible

tightening torque of the respective terminal block.

If the conductor is connected again, the conductor pretreatment

must be repeated.

For flat connection (also PEN/PE rail)

Aluminum conductors must only be connected to the copper busbar

with specially designed cable lugs (cable lugs with galvanic tinning or

Al-/Cu cable lugs).

Page 16

We take care of it.

5.1 Fuse protection

For protection against short circuits and continuous overcurrents, all systems are equipped

with protective devices in accordance with Table 5-1/Table 5-2. In externally fused systems,

the rated current of the fuses must not exceed the rated currents of the respective

systems.

Only after consultation with the A. Eberle Support Team may larger fuses than specified

be used.

5.1.1 Fuse protection for systems with switch-disconnector-fuses

Protective devices

Coordinated fuse protection 400 V L-L

NH fuse gG NH2

32 A (22 kVA system)

63 A (44 kVA system)

100 A (70 kVA system)

160 A (110 kVA system)

200 A (144 kVA system)

250 A (175 kVA system)

355 A (250 kVA system)

NH fuse gTr NH3

630 A (400 kVA system)

910 A (630 kVA system)

Table 5-1 Fuse protection of the systems at the switch-disconnector-fuse block input (400 V

L-L)

Protective devices

Coordinated fuse protection 230 V L-L

NH fuse gG NH2

32 A (13 kVA system)

63 A (26 kVA system)

100 A (41 kVA system)

160 A (64 kVA system)

200 A (84 kVA system)

250 A (101 kVA system)

355 A (145 kVA system)

NH fuse gG NH3

2 x 500 A (400 kVA system)

Table 5-2 Fuse protection of the systems at the switch-disconnector-fuse block input (230 V

L-L)

Page 17

5.1.2 Fuse protection for systems with NH disconnectors

Protective devices

Coordinated fuse protection 400 V L-L

NH fuse gG NH2

32 A (22 kVA system)

63 A (44 kVA system)

100 A (70 kVA system)

160 A (110 kVA system)

200 A (144 kVA system)

250 A (175 kVA system)

355 A (250 kVA system)

NH fuse gTr NH3

630 A (400 kVA system)

910 A (630 kVA system)

Table 5-3 Fuse protection of the systems at the disconnector block input (400 V L-L)

Protective devices

Coordinated fuse protection 230 V L-L

NH fuse gG NH2

32 A (13 kVA system)

63 A (26 kVA system)

100 A (41 kVA system)

160 A (64 kVA system)

200 A (84 kVA system)

250 A (101 kVA system)

355 A (145 kVA system)

NH fuse gG NH3

2 x 500 A (400 kVA system)

Table 5-4 Fuse protection of the systems at the disconnector block input (230 V L-L)

5.1.3 Fuse protection for systems with automatic circuit breakers

Protective devices

Coordinated fuse protection 400 V L-L

Automatic circuit breaker C

32 A (22 kVA system)

63 A (44 kVA system)

100 A (70 kVA system)

Table 5-5 Fuse protection of the systems at the automatic circuit breaker input (400 V L-L)

Protective devices

Coordinated fuse protection 230 V L-L

Automatic circuit breaker C

32 A (13 kVA system)

63 A (26 kVA system)

100 A (41 kVA system)

Table 5-6 Fuse protection of the systems at the automatic circuit breaker input (230 V L-L)

Page 18

We take care of it.

5.2 Fuse protection (internal side)

System

F8 (3x)

F9 (3x)

Resistors Trafo

big-X2

Resistors

Trafo small-X2

32 A 6 % to

32 A 10 %

D01GG40V16

582.1203

X

MI5HT25V0,63

582.1020.00.63

MI5HT25V0,63

582.1020.00.63

63 A 6 % to

160 A 6 %

D02GG40V25

582.1205

X

MI5HT25V2

582.1020.02

MI5HT25V0,63

582.1020.00.63

160 A 8 % to

160 A 10 %

D02GG40V25

582.1205

X

MI5HT25V5

582.1020.05

MI5HT25V1

582.1020.01

200 A 6 % to

355 A 8 %

D02GG40V40

582.1207

X

MI5HT25V5

582.1020.05

MI5HT25V2

582.1020.02

355 A 10 % to

580 A 8 %

NH00GR50V80

582.1246

D02GG40V25

582.1205

MI5HT25V8

582.1020.08

MI5HT25V5

582.1020.05

580 A 10 % to

910 A 6 %

NH00GR50V100

582.1247

D02GG40V35

582.1206

MI5HT25V8

582.1020.08

MI5HT25V5

582.1020.05

910 A 8 % to

910 A 10 %

NH00GR50V125

D02GG40V50

582.1208

MI6SA12,5V25

MI5HT25V6,3

582.1020.06.30

Table 5-7 Protection of the systems internal side

Measuring voltage taps Output voltage (XF) are protected with G-fuse links super-fast FA

5x20 3.15 A (MI5FA25V3.15 / 582.1018). Measuring Voltages Input voltage (XF) are

protected by G-fuse links super-fast FA 6.3x32 3.15 A (MI6FA25V3.15).

Table of contents

Other a-eberle Controllers manuals

Popular Controllers manuals by other brands

MKS

MKS HPS 947 Series Operation and maintenance manual

Neuralynx

Neuralynx SpectraLynx quick start guide

Atkinson Electronics

Atkinson Electronics PVLC-40MD quick start guide

Evco

Evco EV3 Mix instructions

Unitronics

Unitronics Vision OPLC V130 Replacing

Maguire Products

Maguire Products Weigh Scale Blender WSB Operation & maintenance manual