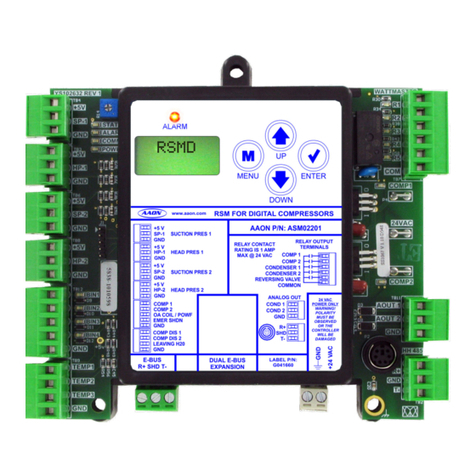

7RSMD2R Technical Guide

INSTALLATION AND WIRING

Electrical Environmental Requirements

General

Correct wiring of the main unit controller and its modules is the most

important factor in the overall success of the controller installation

process. The main unit controller and modules are factory installed

and wired at the AAON factory. Some of the following information

may not apply to your installation if it was pre-wired at the factory.

However, if troubleshooting of the controller or modules is required,

it is a good idea to be familiar with the system wiring.

Wiring

The modules must be connected to an 18-30 VAC power source

of the proper size for the calculated VA load requirements. All

transformer sizing should be based on the VA ratings listed in Table

1, this page.

NOTE: If the temperature at the controller is below -4ºF

(-20ºC), the display refresh rate could be less

responsive.

WARNING: When using a single transformer to power

more than one controller or expansion module,

the correct polarity must always be maintained

between the boards. Failure to observe

correct polarity will result in damage to the

unit controller, RSMD2R, and any associated

module.

Please carefully read and apply the following information when

wiring the unit controller, RSMD2R, and any associated module.

1. All wiring is to be in accordance with local and national

electrical codes and specications.

2. All 24 VAC wiring must be connected so that all ground

wires remain common. Failure to follow this procedure

can result in damage to the controller and connected

devices.

3. Minimum wire size for 24 VAC wiring should be

18-gauge.

4. Minimum wire size for all sensors should be 24-gauge.

Some sensors require two-conductor wire and some

require three-or four-conductor wire.

5. Minimum wire size for 24 VAC thermostat wiring should

be 22-gauge.

6. Be sure that all wiring connections are properly inserted

and tightened into the terminal blocks. Do not allow wire

strands to stick out and touch adjoining terminals which

could potentially cause a short circuit.

7. When communication wiring is to be used to interconnect

HVAC Unit Controllers together or to connect to other

communication devices, all wiring must be plenum-rated,

minimum 18-gauge, two-conductor, twisted pair with

shield. AAON can supply communication wire that meets

this specication and is color coded for the network or

local loop. Please consult your AAON distributor for

information. If desired, Belden #82760 or equivalent

wire may also be used.

8. Before applying power to the HVAC Unit Controller,

RSMD2Rs, and any associated modules, be sure

to recheck all wiring connections and terminations

thoroughly.

Powering Up

When the controller and modules are rst powered up, the POWER

LED should light up and stay on continuously. If it does not light up,

check to be sure that you have 24 VAC connected to the controller,

that the wiring connections are tight, and that they are wired for the

correct polarity. The 24 VAC power must be connected so that all

ground wires remain common. If after making all these checks, the

POWER LED does not light up, please contact AAON Controls

Support for assistance.

Control

Device

Voltage

VA Load

Operating

Temperature

Humidity

(Non-

Condensing)

RSMD2R

Controller

18-30VAC 18 -4°F to 158°F

-20ºC to 70ºC 0-95% RH

Inputs

Resistive Inputs require 10KΩ

Type 3 Thermistor

24VAC Inputs provide 4.7kΩ Load

Outputs Relay Outputs: 1 Amp

maximum per output.

Table 1: RSMD2R Controller Electrical and

Environmental Requirements