3BNP102777D017 G

ABB AbilityTM Smart Sensor EX User Manual

Smart Sensor XYZW

Smart Sensor variant

XYZW Description Article

Number Product

Revision

Smart Sensor BASA Bluetooth, Standard Performance 4JNO000026R002 A

Smart Sensor HCHC WirelessHART, High performance, Long life 4JNO000026R003 A

Smart Sensor BCHC Bluetooth, High performance, Long life 4JNO000026R004 A

ABB AbilityTM Smart Sensor product coding XYZW:

X: Host comm. Type Y: Power / battery Z: Sensor & IO W:Encapsulation type

B: Bluetooth A: 2.4 Ahbattery S: Standard performance A

H: WirelessHART C: 8.5 Ah battery H: High performance C

Smart Sensor is certified for mounting in mines (group I), gas hazard zone 0 (group IIC) and dust

hazard zone 20, indoor and outdoor, according to standards as defined below. For full standard

compliance see “Declaration of Conformity”.

EN/IEC60079-0: 2018/2017, Explosive atmospheres: Equipment – General requirements

EN/IEC60079-11:2012/2011, Explosive atmospheres: Equipment protection by intrinsic safety "i"

EN 50303:2000 GroupI, Category M1 equipment intended to remain

functional in atmospheres endangered by firedampand/or

coal dust

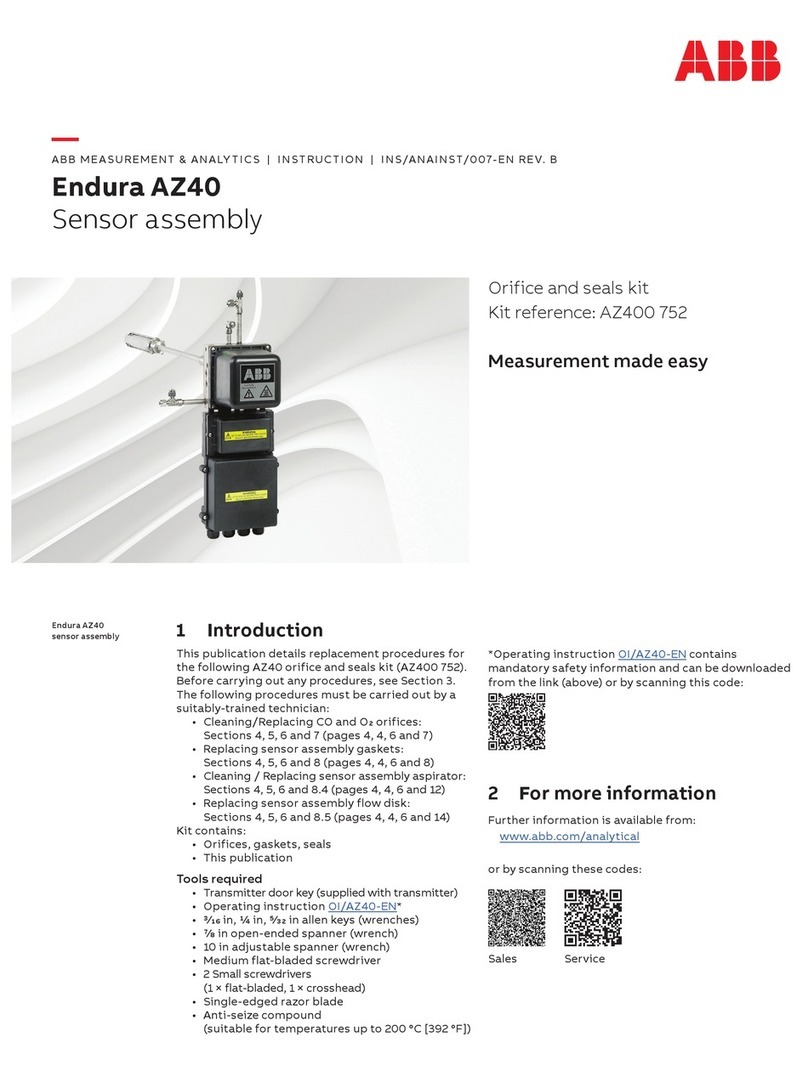

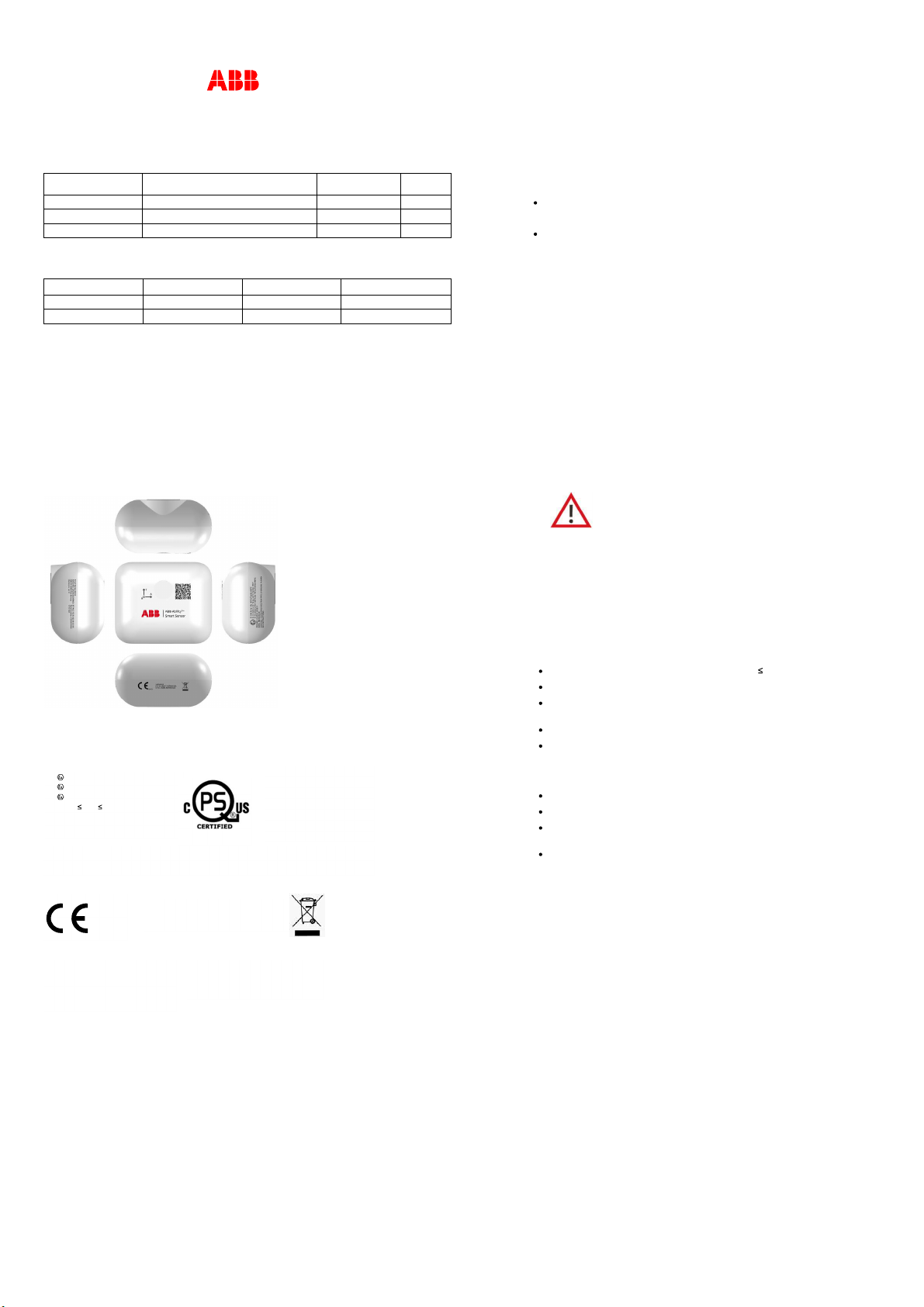

Figure 1 ABB AbilityTM Smart Sensor Enclosure

1. Marking on modules

2. Feasible locations for use of Smart Sensor

ABB Ability Smart Sensor is feasible for use in the following hazardous areas:

(a) In-door and outdoor

(b) Mines

(c) Locations with danger for explosive gas

(d) Locations with conductive or non-conductive dust

3. Special conditions for mounting hazardous areas

3.1 Earthing of sensor

To avoid possibility for buildup of charge on sensor, it is required to connect the sensor to

a metallic surface (with threaded hole for M6 or ¼’’ 28 UNF screw) which is connected to

earth.

3.2 Avoidance of electrostatic discharge

Under dry conditions, the surface of the Smart Sensor may accumulate electrostatic

discharge. To avoid this to happen, the following precautions shall be done:

Avoid using a dry cloth when cleaning, or touching with other isolating objects (use

wet cleaning equipment)

Avoid installations locations with direct air flow, or protect from airflow

3.3 Mechanical damages

If enclosure is damaged by mechanical or chemical reasons, the sensor shall be

removed from Ex zone as soon as reasonable possible.

4. Installation

4.1 Mechanical

Installation is done by using M6 or ¼’’ -28 UNF socket head screws. Installation is done

on dedicated points with threaded holes pre-prepared on machine, or by using mounting

adapters for machine cooling ribs or for gluing on flat or curved surfaces.

For good connection to bearing vibrations, mounting on metal surface in direct

connection to bearing outer ring is recommended.

For best possible pickup of motor magnetic field, motor side mounting is recommended.

When installation in Ex zone, make sure that there is electric connection between sensor

metal base and machine below.

For detailed mounting instructions see “Smart Sensor Installation Manual” available on

the Smart Sensor product website.

Use a torque wrench, torque approx.. 10 Nm applied on the

screw, to give sufficient pressure between machine and sensor.

This gives good pickup of vibration and reduces risk for

loosening sensor by unintentional twisting.

4.2 Sensitivity to electric fields

Avoid having unshielded power cables crossing in the immediate proximity of the Smart

Sensor. This may create false high frequency vibration signals

5. Environment

The operating temperatures are from -40°C to +85°C

IP degree IP66, dust tight and protected against powerful jets of water

Pollution degree 4 according to definition in IEC 61010-1, continuous conductivity

due to conductive dust, rain or other wet conditions

Air humidity 0% - 100% condensing

There are no restrictions on installation altitude

6. Radio performance

Aim for free line of sight for optimal communication

Aim for installation with distance to ground (if possible >1 m)

See Smart Sensor User Manual available on product WEB page for detailed

information on how to achieve best possible radio performance

With WirelessHART, improved distance and performance can be achieved by

adding repeater sensors at good locations

7. Radio certification statements

Modification statement:

Changes or modifications to the equipment will void the user's authority to operate the

equipment.

Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Class A Interference Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

II 1 G Ex ia IIC T4 Ga

II 1 D Ex iaIIIC T157°C Da

-40°C Tamb +85°C

PRESAFE 19 ATEX 14930X

IECEx PRE 19.0044X LR1608-1

WARNING – POTENTIAL ELECTROSTATIC CHARGING HAZARD –SEE INSTRUCTIONS

AVERTISSEMENT - RISQUE DE CHARGE ÉLECTROSTATIQUE

Cl I, Zn0, AEx ia I Ma

Cl I, Zn0, AEx ia IIC T4 Ga

Zn 20, AEx ia IIIC T157°C Da

Cl I, Div 1, Gr A, B,C and D T4

Cl II, Div 1, Gr E, F and G T4

Cl III, Div 1

0470

Contained

FCC ID:2ANYT-SSPM00xAA

IC no: 23283-SSPM00xAA

Serial number: C2xxxxxxxx

BT MAC: 50:31:AD:XX:XX:XX

WH MAC: 001B1E1A9AXXXXXX

Smart Sensor xxxx

Article No: 4JNO000026R00x

ABB AS 0666 Oslo Norway

Ole Deviks vei 10