Document: v0.4 / Document No.: 6AGA000008-0607-EN | Date: 22-05-2019 Page 5of 25

Glossary

AC

Alternating Current.

ACM

ACS Control Module

ACS

Automatic Control System. In this charger

system the pantograph.

CAF

Customer Acceptance Form.

Charge control set

Set of sub-system of the charger systems

which includes theACS, the control module

for the ACS, the communication unit and a

status indicator of the charge process.

DC

Direct Current.

Grid provider

Company responsible for the

transportation and distribution of electricity.

HMI

Human Machine Interface; the screen on

the charger.

HVC

Heavy Vehicle Charger.

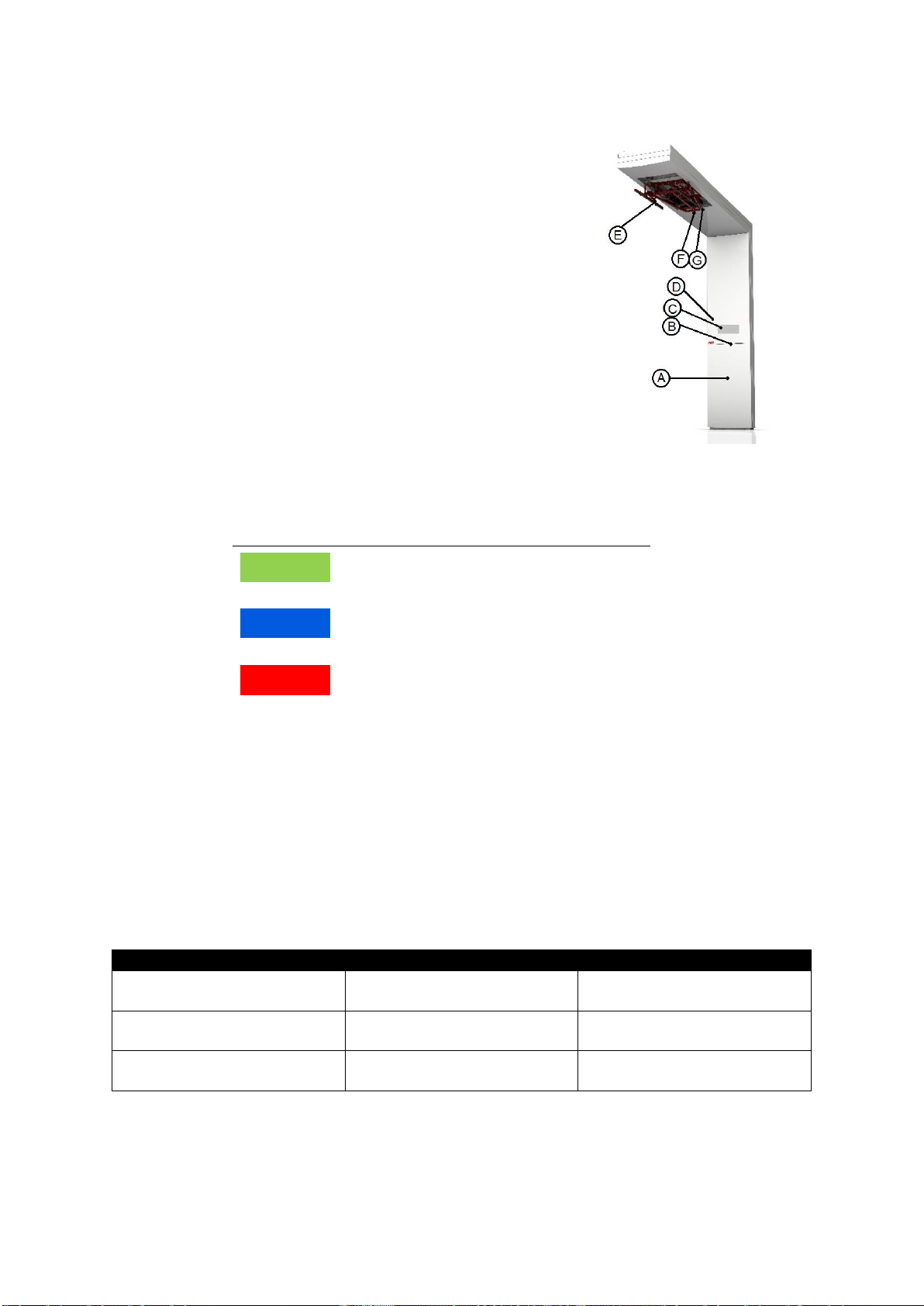

Power Cabinet

Intermediate unit that provides 150 kW of

DC power to the Charge control set. Gets

its power from a power distribution board.

Interlock

The Interlock is an isolated current loop

and is a feature that makes the state of two

mechanisms or functions mutually

dependent.

LAN

A computer network that interconnects

computers systems within a limited area.

NOC

ABB Network Operating Centre; remotely

checks the correct functioning of the

charger.

MCB

Mechanical Circuit Breaker

OppCharge

Is a trade name of fast charging method for

electric vehicles.

Owner

The legal owner of the charger.

Pantograph

The mechanical contact linkage of the

charger through which the DC charge

power is electrical transported to the

electrical vehicle.

PE

Protective Earth.

PPE

Personal Protective Equipment. Equipment

such as safety shoes, helmet, glasses,

gloves.

RCD

Residual-Current Device.

RFID

Radio-Frequency IDentification. RFID is a

communication technology by means of

radio waves to transfer data over a very

short distance between a reader and an

electronic tag or card.

Site operator

The entity is responsible for the day to day

control of the charger. The site operator

can be the owner, but not necessarily.

User

The owner of an electric vehicle, who uses

the Charge Station to charge that vehicle.

WiFi

A technology that allows electronic devices

to connect to a wireless LAN (WLAN)

network.