6

Table of contents

Safety Instructions 3

Table of contents 6

DCT880 Manuals and Tools 8

List of manuals............................................................................................................................................... 8

Documentation............................................................................................................................................... 9

DCT880 Information....................................................................................................................................... 9

Introduction 10

Chapter overview ..................................................................................................................................... 10

Before You Start ...................................................................................................................................... 10

What this manual contains....................................................................................................................... 10

Target group ............................................................................................................................................ 10

Associated publications ........................................................................................................................... 10

Storage and transport .............................................................................................................................. 10

Name plate................................................................................................................................................... 11

Type code .................................................................................................................................................... 11

Ratings ......................................................................................................................................................... 11

Voltage ratings ......................................................................................................................................... 11

400 V / 525 V units, current and power ratings ....................................................................................... 12

690 V units, current and power ratings .................................................................................................... 12

Fault Tracing Thyristors 14

Tools ............................................................................................................................................................ 14

For commissioning and fault tracing ........................................................................................................ 14

Additionally for service and preventive maintenance .............................................................................. 15

How to detect a faulty thyristor .................................................................................................................... 15

A fuse is blown......................................................................................................................................... 15

Output current measured by an oscilloscope .......................................................................................... 15

Thyristor diagnosis................................................................................................................................... 16

How to find a faulty thyristor ........................................................................................................................ 16

Standard thyristor power controllers size T1 … T4 (20 A ... 740 A), without +S500 ............................... 16

Blown fuses.............................................................................................................................................. 16

Faulty thyristor ......................................................................................................................................... 16

Standard thyristor power controllers size T5 (890 A … 960 A), without +S500 ...................................... 17

Blown fuses.............................................................................................................................................. 17

Faulty thyristor ......................................................................................................................................... 17

Thyristor power controllers size T1 … T4 (20 A ... 740 A), with +S500................................................... 17

Blown fuses.............................................................................................................................................. 18

Faulty thyristor ......................................................................................................................................... 18

Handling the Semiconductors 19

General Instruction how to handle semiconductors..................................................................................... 19

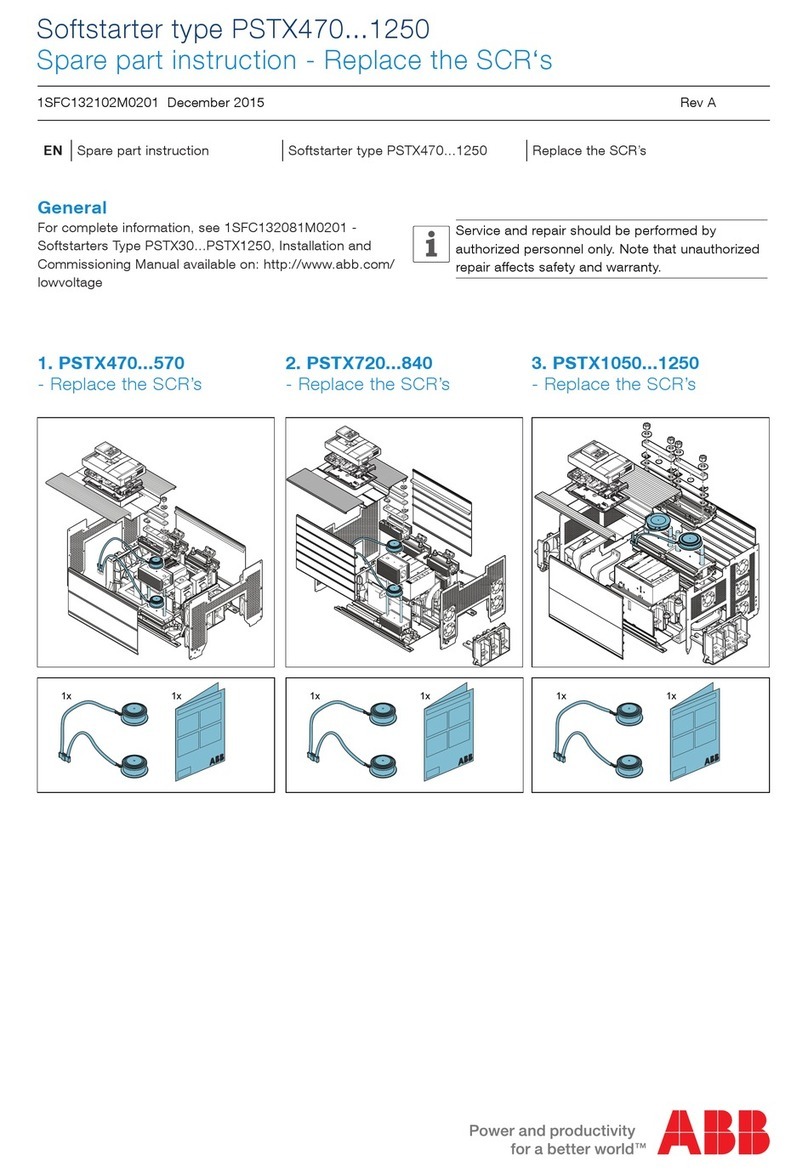

Exchange thyristors sizes T1 … T4 20

Installation of thyristor modules in thyristor power controllers size T1 … T4 (20 A ... 740 A) ..................... 20

Required tools.......................................................................................................................................... 20

Find faulty thyristor modules.................................................................................................................... 20

Remove faulty thyristor modules ............................................................................................................. 21

Install new thyristor modules ................................................................................................................... 26

Thyristor module terminals ...................................................................................................................... 27

Exchange thyristors size T5 29

Installation of thyristor modules in thyristor power controllers size T5 (890 A … 960 A) ............................ 29

Table of contents

3ADW000449R0101 DCT880 Service Manual e a