ABB ACS880-01 Series User manual

Other ABB Controllers manuals

ABB

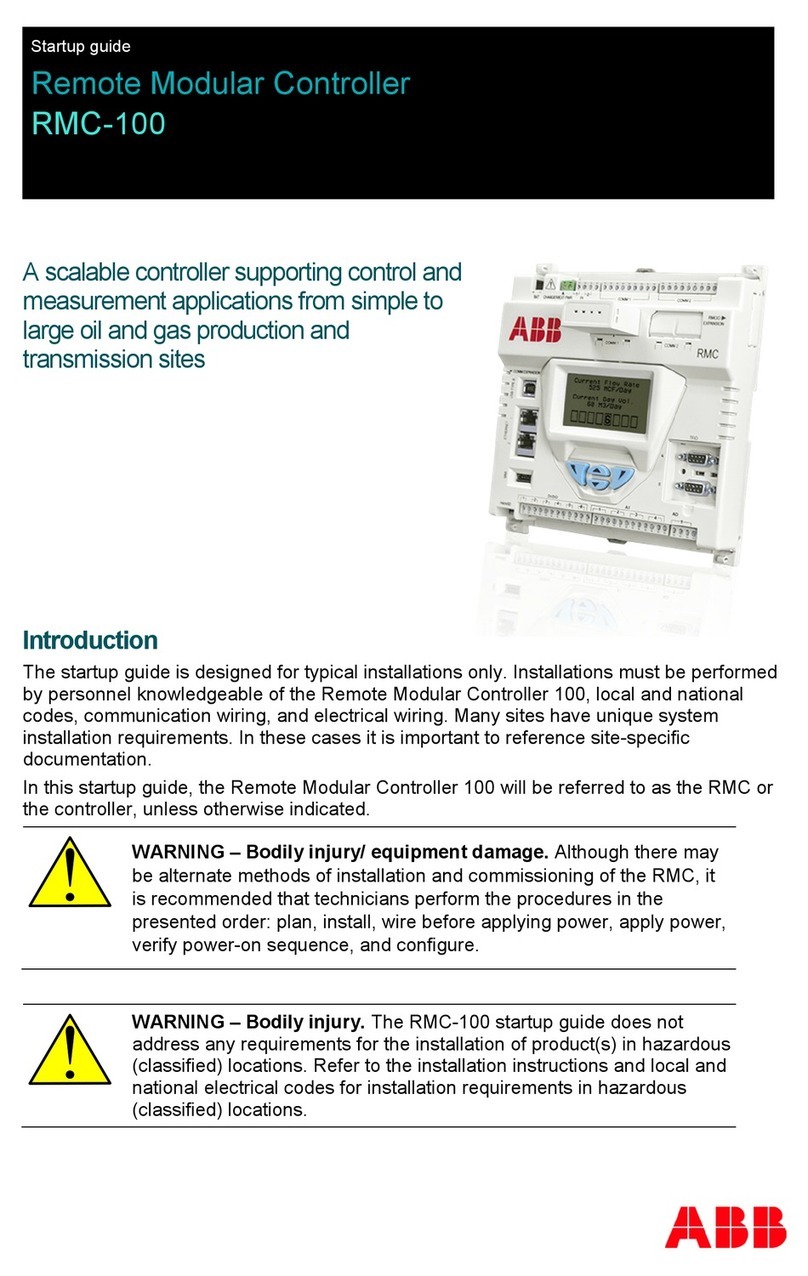

ABB RMC-100 User guide

ABB

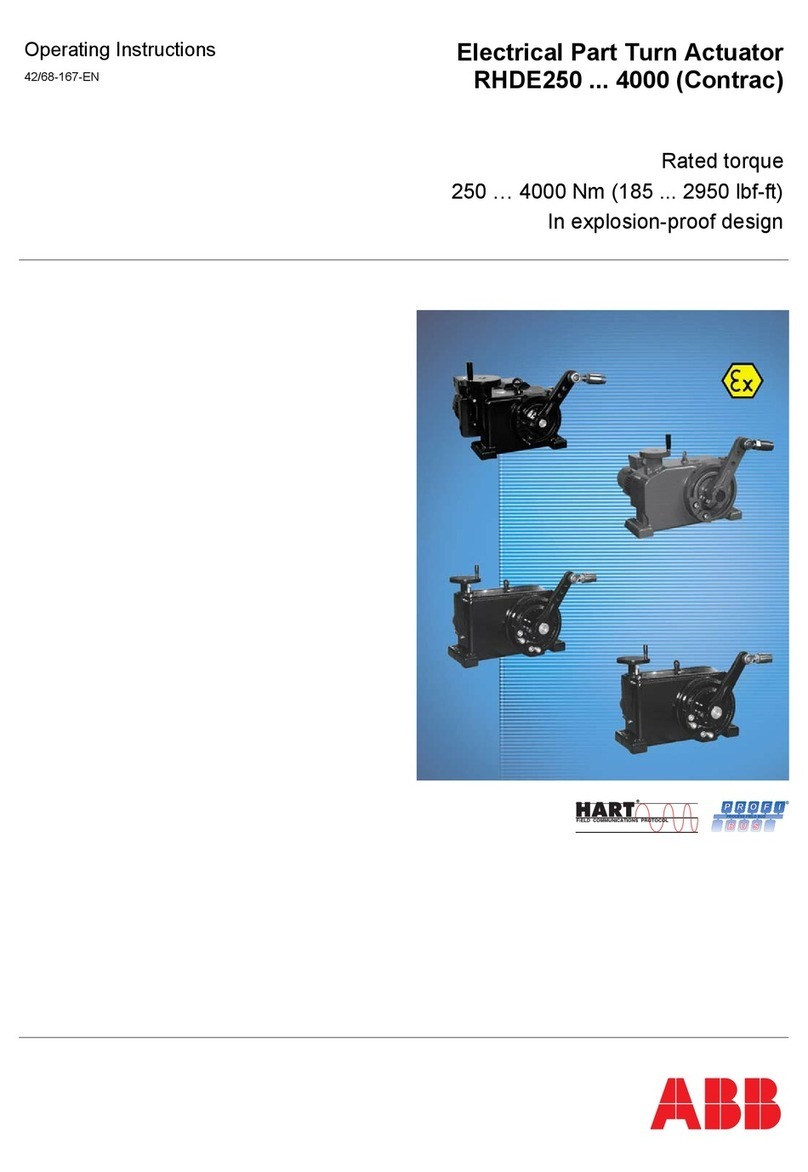

ABB RHDE250 User manual

ABB

ABB ACS 600 MultiDrive User manual

ABB

ABB i-bus SA/S 12.16.6.1 User manual

ABB

ABB AC500 Series User manual

ABB

ABB Welcome M2300 User manual

ABB

ABB AC 800F Installation and operation manual

ABB

ABB COMMANDER 500 User manual

ABB

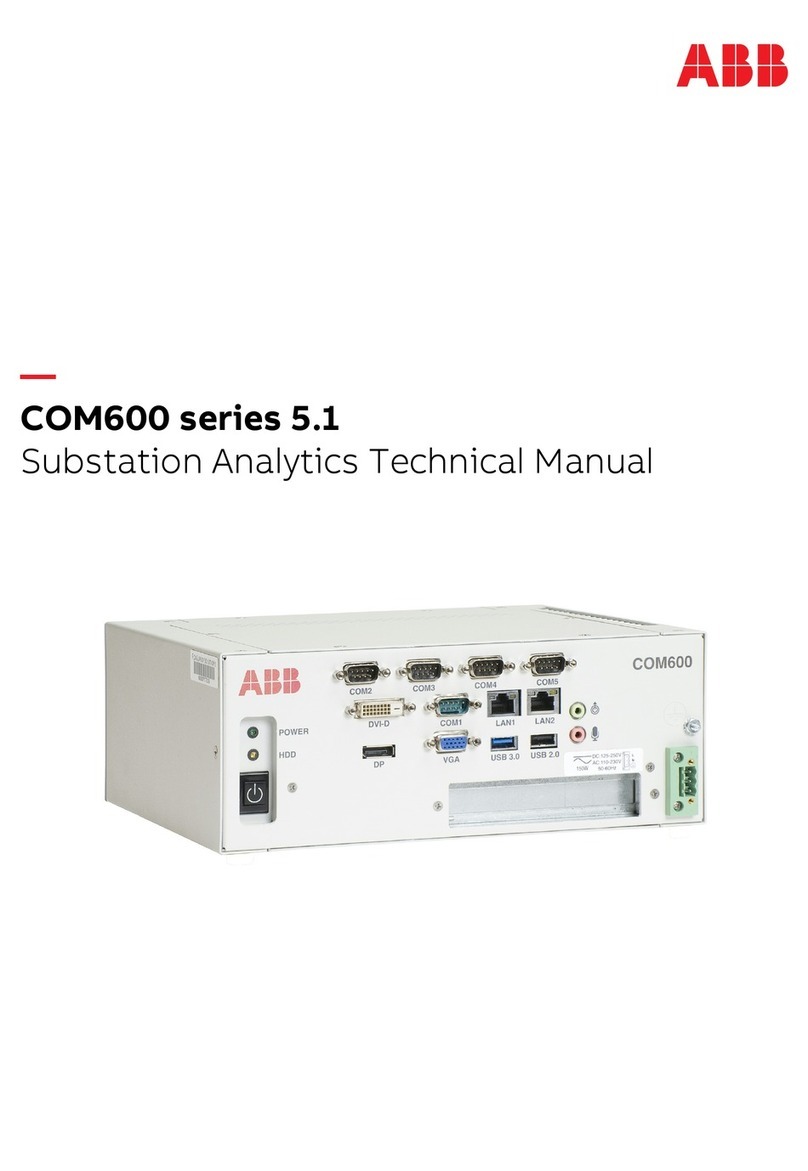

ABB COM600 series User manual

ABB

ABB i-bus EIB/KNX AA/S 4.1 User manual

ABB

ABB PLUTO Safety-PLC User guide

ABB

ABB COM600 series User manual

ABB

ABB MS132-32-HKF1-11 User manual

ABB

ABB ACQ580 Troubleshooting guide

ABB

ABB PS D75 840 Series Technical specifications

ABB

ABB ACS550 Series User manual

ABB

ABB IRC5 Compact Instructions for use

ABB

ABB ACQ810-04 User manual

ABB

ABB AC500-eCo Starter-Kit User manual

ABB

ABB ACS880-37 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions