3

1. Introduction .....................................................................................................................................................5

1.1. General.................................................................................................................................................5

1.2. Intended application.........................................................................................................................6

1.3. Warranty ..............................................................................................................................................6

1.4. Information on electromagnetic compatibility...........................................................................6

1.5. Required qualifications for personnel who handle the motor .................................................6

1.6. Manual and related documents ...................................................................................................... 7

1.7. Safety................................................................................................................................................... 7

1.8. Contraindications.............................................................................................................................. 7

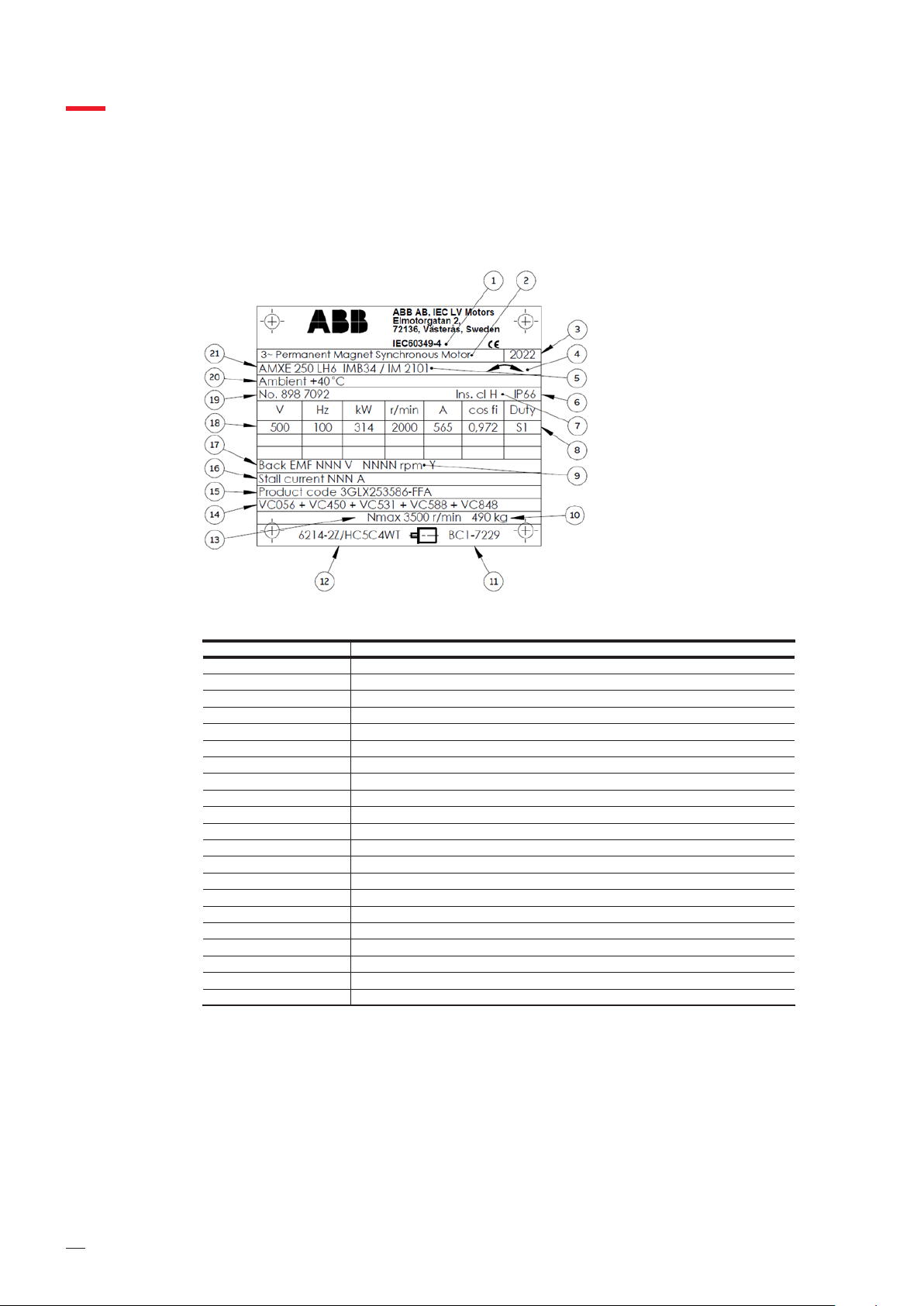

2. Product description .......................................................................................................................................8

2.1. Technical data .................................................................................................................................. 10

2.2. Expected lifetime..............................................................................................................................11

3. Transportation and Storage....................................................................................................................... 12

3.1. Transportation................................................................................................................................. 12

3.1.1. Delivery to customer ..................................................................................................... 12

3.1.2. Inspection of delivery..................................................................................................... 12

3.1.3. Lifting of motor .............................................................................................................. 13

3.2. Storage ............................................................................................................................................. 15

3.3. Removal of corrosion protection before commissioning........................................................ 15

3.4. Insulation resistance check ........................................................................................................... 15

4. Motor installation.......................................................................................................................................... 16

4.1. Preparation and lifting ................................................................................................................... 16

4.2. Installation of coupling .................................................................................................................. 16

4.3. Installation of motor........................................................................................................................17

4.3.1. Flange mount....................................................................................................................17

4.3.2. Side mounts......................................................................................................................17

4.4. Liquid cooling system installation ............................................................................................... 18

4.5. Electrical installation ...................................................................................................................... 19

4.5.1. Connection of power supply.........................................................................................20

4.5.2. Earth point ....................................................................................................................... 21

4.5.3. Auxiliary connection ....................................................................................................... 21

5. Operation........................................................................................................................................................22

5.1. Failure mode operation..................................................................................................................22

6. Inspection and maintenance ......................................................................................................................23

6.1. Inspection and maintenance intervals ........................................................................................24

6.2. Inspection and maintenance actions ..........................................................................................24

6.2.1. Visual inspection.............................................................................................................24

6.2.2. Detailed visual inspection.............................................................................................24

6.2.3. Bearings............................................................................................................................25

6.2.4. External shaft seal ..........................................................................................................25

6.2.5. Shaft spline ......................................................................................................................25

6.2.6. External cleaning.............................................................................................................25

6.2.7. Touch-up painting...........................................................................................................26

—

Table of contents