Installation and commissioning guide

1ZSC000563-AAF EN, REV. 4, 2021-06-23

3

Contents

1 Safety 5

1.1 Levels of safety risks ................................................................................................................................................................... 5

1.2 Hazardous working situations ..................................................................................................................................................... 6

1.3 Safety precautions....................................................................................................................................................................... 6

1.4 Competence level........................................................................................................................................................................ 6

2 Product description 7

2.1 Design ......................................................................................................................................................................................... 7

2.2 Technical specifications............................................................................................................................................................... 10

2.2.1 General specifications ............................................................................................................................................... 10

2.2.2 Mechanical loading.................................................................................................................................................... 11

3 Delivery 13

3.1 Incoming inspection..................................................................................................................................................................... 13

3.2 Transportation ............................................................................................................................................................................. 13

3.3 Storage........................................................................................................................................................................................ 13

3.4 Lifting........................................................................................................................................................................................... 14

3.4.1 Lifting the transport box............................................................................................................................................. 14

3.4.2 Lifting the bushing out of the transport box ............................................................................................................... 15

4 Installation 19

4.1 Tools ............................................................................................................................................................................................ 19

4.2 Consumables .............................................................................................................................................................................. 19

4.3 Preparations ................................................................................................................................................................................ 20

4.3.1 Installation of lifting tools ........................................................................................................................................... 20

4.3.2 Lifting the bushing for installation on the transformer................................................................................................ 22

4.4 Installation at the transformer factory .......................................................................................................................................... 24

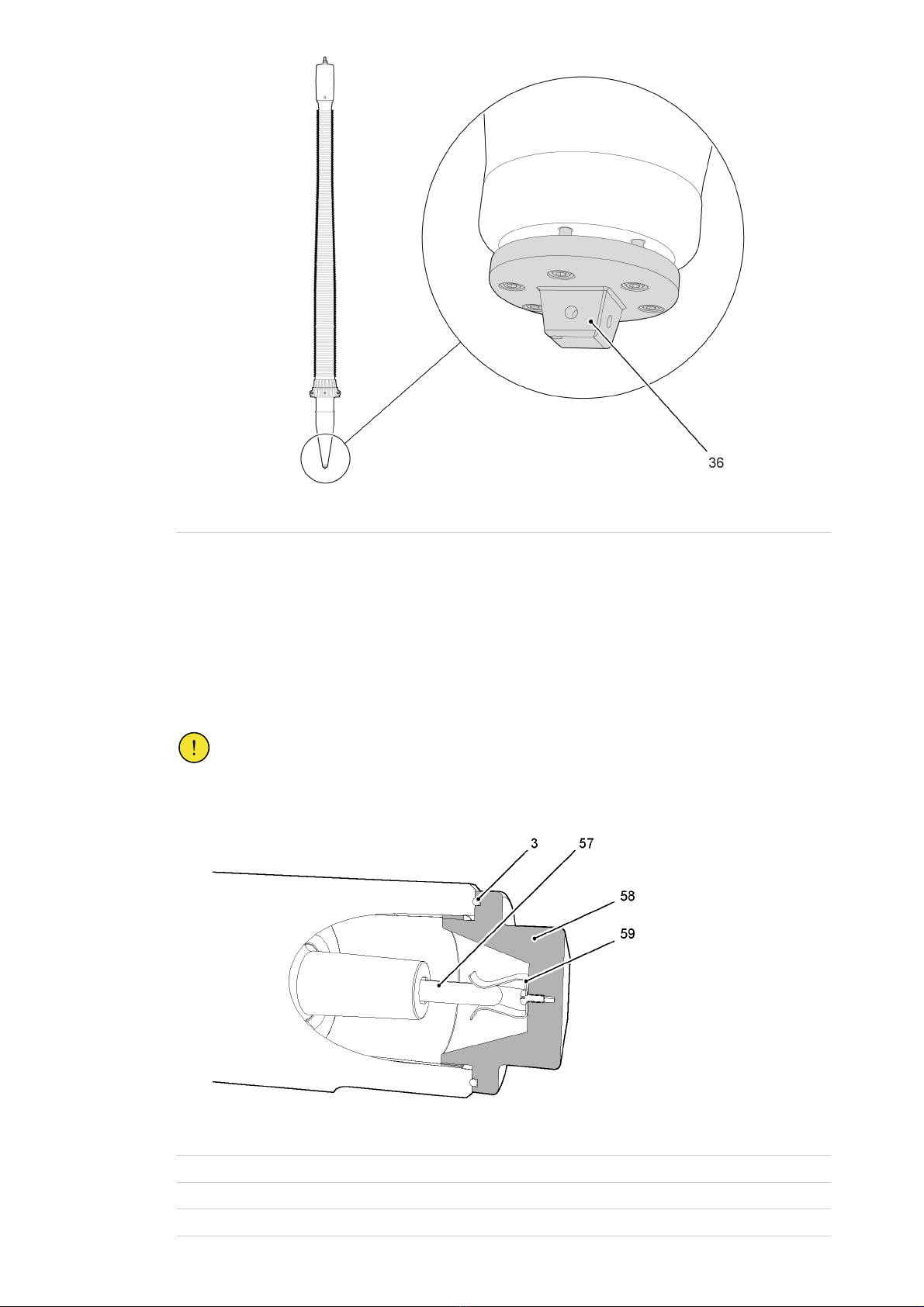

4.4.1 Removal of the lower draw rod with bottom contact from the bushing ..................................................................... 24

4.4.2 Installation of the small bottom contact (N1=4) in the transformer ............................................................................ 27

4.4.3 Installation of the large bottom contact (N1=6) in the transformer ............................................................................ 29

4.4.4 Installation of the bushing on the transformer ........................................................................................................... 31

4.4.5 Installation of the bushing with the fixed bottom contact ........................................................................................... 34

4.5 Installation at site......................................................................................................................................................................... 36

4.5.1 Preparations at site ................................................................................................................................................... 36

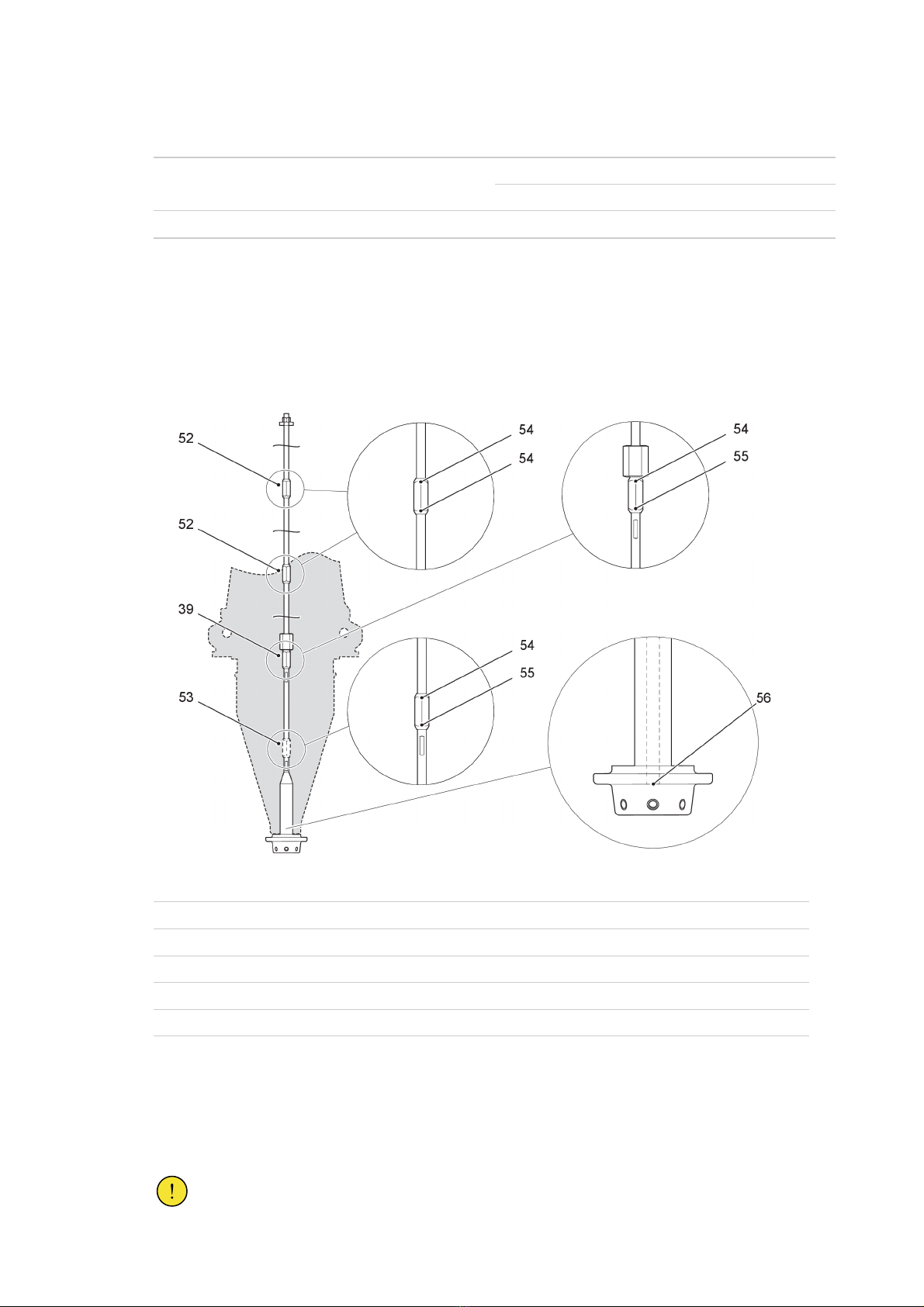

4.5.2 Installation of the bushing on the transformer at site................................................................................................. 39

4.5.3 Installation of the bushing with the fixed bottom contact ........................................................................................... 34

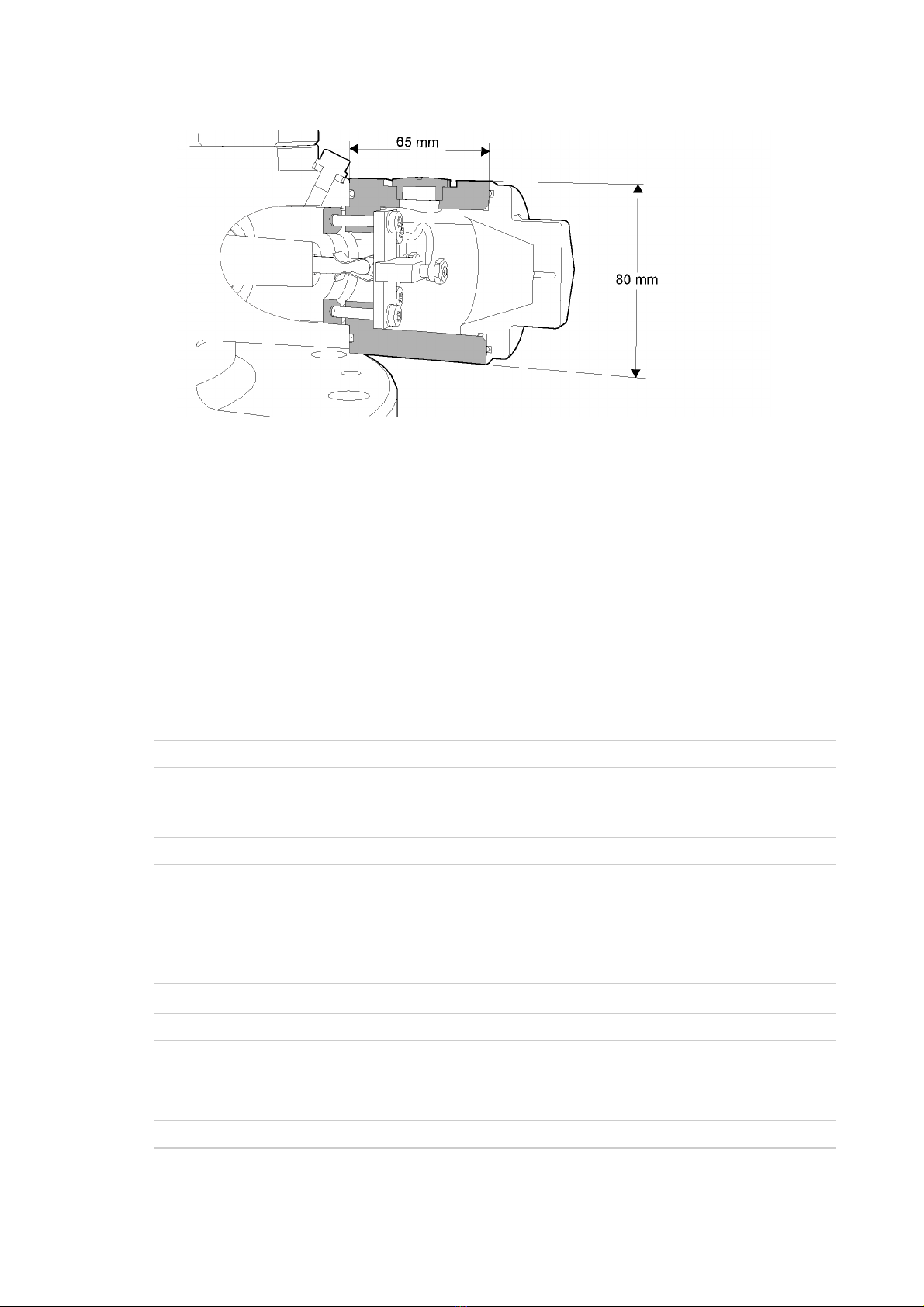

4.6 Hydraulic tightening of the draw-rod nut...................................................................................................................................... 45

4.7 Minimum oil-level in transformer ................................................................................................................................................. 49

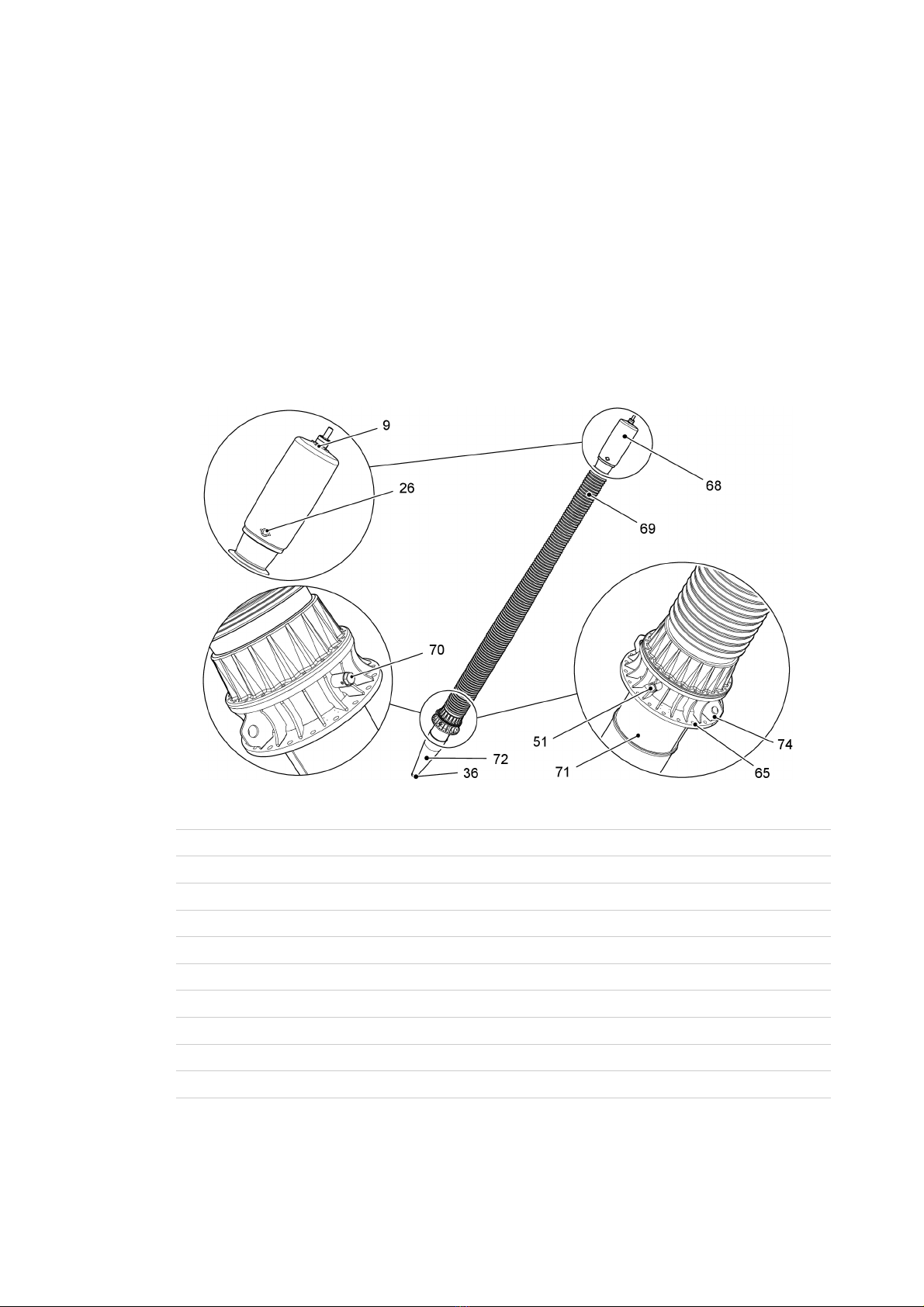

4.8 Installation of the outer terminal .................................................................................................................................................. 49

4.9 Grounding of the bushing flange ................................................................................................................................................. 52